Sebacic acid stepped onto the scene at a time when natural resources were shaping chemistry labs more than petrochemicals. People in India first found ways to pull it from castor oil, an everyday crop in their region. European chemists took note, and by the turn of the 20th century, the material started pushing into everything from early plastics to lubricating greases. Factories changed as demand grew, with the focus shifting from labor-intensive extraction to reliable, scalable manufacturing. This progress unlocked the possibility of advanced nylon fibers, lasting coatings, and flexible plastics, setting up a foundation for today’s specialty chemicals industry.

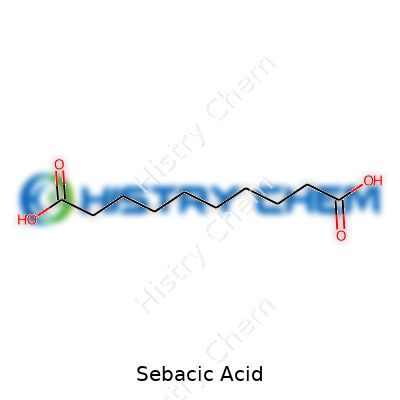

Sebacic acid stands as a ten-carbon dicarboxylic acid, giving it flexibility when blended into polymers. Its structure lets it play the backbone in tough nylon types such as nylon 6,10, used in bristles, gears, and fuel lines. Industrial plants package it as a fine, white powder, making it easy to mix and ship. In some circles, its reputation comes more from what gets built with it—heat-resistant plastics, bio-based polyesters, corrosion inhibitors, and high-grade lubricants. End-users look for reliable supply chains, consistent product specs, and a steady purity that won’t wreck batches further down the line.

Sebacic acid melts around 133 degrees Celsius and boils past 294 degrees, with a solid, powdery texture. The substance dissolves in alcohol and ether while staying hardy in water. Its stability helps it hold up well under pressure and heat, crucial during polymerization. More than that, its dicarboxylic nature means both ends can bond in reactions, an open invitation for chemists to make stronger, more flexible materials. The acid has little taste and no color, but anyone handling large amounts gets a whiff—a mild, fatty smell lingering in the air.

Manufacturers fixate on purity. Most customers demand at least 99 percent pure Sebacic acid, stripped of residual oils or unwanted byproducts. Packaging labels mark batch numbers, country of origin, weight, and recommended storage conditions—usually cool, dry, and airtight—to keep moisture and foreign particles at bay. Quality checks follow strict industry standards, often set by ASTM or ISO, which audit things like melting point, moisture content, and particle size. Certificates of analysis travel with each drum or bag, a paper trail meant to keep producers and buyers honest.

Castor oil starts the journey for nearly every batch of Sebacic acid. First, chemists saponify the oil, splitting it with a strong base to get ricinoleic acid. High temperatures and pressure send this acid through a cracking process, slicing up the long molecules into shorter fragments, with Sebacic acid and octanol as chief products. Some setups recycle heat from this split, cutting costs and waste. Tech upgrades have streamlined the job, using stainless steel reactors, better catalysts, and real-time analysis to reduce byproducts and sharpen yields. By-products find their own markets, sometimes feeding into flavors, fragrances, or alternative fuels.

The two carboxylic groups on Sebacic acid offer a playground for chemical reactions. Chemists routinely convert it into esters for use in biodegradable lubricants and plasticizers. Reacting the acid with diamines produces nylon, specifically nylon 6,10, valued for toughness and low friction. Suppliers also tweak the backbone to create alkyd resins for paints or polyurethane foams with built-in fire resistance. Its structure lets researchers experiment with cross-linked gels or drug delivery systems, making it a staple in labs where new materials take shape faster than regulatory codes can keep up.

Sebacic acid takes on different names in the lab and on the loading dock. Chemists jot down "decanedioic acid" on paperwork, a nod to its ten-carbon chain. Industrial buyers spot synonyms such as 1,8-octanedicarboxylic acid. Specialty brands and chemical retailers stamp proprietary product codes and trade names, though the base ingredient rarely changes. In global trade, customs forms might list any of these, and knowing the aliases eases international shipments. Mislabeling has cost companies plenty, either through delayed shipments or fines for safety misclassification.

Workplace safety, more than anything, drives trust in suppliers. Material safety data sheets warn about dust inhalation and skin irritation, though the acid isn’t fierce like some industrial reagents. Ventilation, gloves, and eye protection form the basic defense, and storage in sealed bins limits air exposure. OSHA and EU REACH regulations rank this substance with mild irritants but demand tracking and containment in case of spills. Fire response teams learn to handle it as a combustible organic powder, especially in dust-prone factories. Training and signage matter here—the difference between a safe shift and a workplace incident often comes down to routine and oversight.

A run through any plastics plant, cosmetics lab, or automotive parts factory turns up Sebacic acid in surprising places. It gives nylon toothbrush bristles their snap, shapes casings for electronics, and finds its way into engine coolants or plasticizers for soft PVC. Medical researchers appreciate the biocompatibility; they use it in slow-release drug carriers and tissue scaffolds. The cosmetics world takes advantage of its softening power, folding it into creams, lotions, and specialty soaps. Sustainability experts value its renewable source, usually castor oil—a step up from most fossil-derived chemicals crowding the market.

Academic and corporate labs stay busy looking for new tricks Sebacic acid can pull. University papers highlight its role in green chemistry, especially in biodegradable plastics that rot down cleanly. Big chemical companies pour money into better catalysts and energy-efficient reaction routes. Innovation spreads from classic uses—like nylon or lubricants—out into new bio-polyesters, carbon-neutral fuels, and lightweight composites for cars or phones. Collaboration between public and private sectors—sometimes between competitors—has sped up patent filings and tech licensing, tightening the gap between basic research and commercial rollout.

Toxicologists dig deeper than surface warnings. Current research shows Sebacic acid posing low threat to humans and the environment, with test animals tolerating large doses before side effects appear. Environmental fate studies show little buildup in waterways or soil, as microbes break it down quickly. This profile helps push biobased alternatives in sensitive applications like packaging or cosmetics. Still, labs remain ready to flag unexpected bioaccumulation or side effects, and companies investing in new uses monitor risk assessments to preempt regulatory headaches.

Looking ahead, the spotlight will stay on renewable sourcing and sustainability. The world’s push to cut plastic waste has brightened prospects for Sebacic acid in biodegradable packaging, green lubricants, and next-generation medical materials. Castor farmers could see higher demand if trends keep moving toward biopolymers, especially in Asia and South America where supply chains grow fast. Stricter environmental standards might nudge chemical giants to speed up research into energy-saving production or to widen the use of byproducts. Tech advances—especially in fermentation, process intensification, and catalyst design—stand to lower costs and carbon footprints even further, promising a future where Sebacic acid underpins everyday products with a smaller environmental toll.

People rarely stop to think about the backstory behind nylon fabrics or the lubricants that keep machines running smoothly. Sebacic acid, a white powdery compound derived from castor oil, plays a big part in these everyday materials. As someone who appreciates innovation that goes beyond buzzwords, I like getting into the real reason why a material like sebacic acid keeps showing up in so many surprising places.

Some of the softest and most flexible nylon fibers come together using sebacic acid. While nylon 6,6 often gets most of the attention, nylon 6,10—made using sebacic acid—brings real creativity to the mix. It’s lighter, absorbs less water, and resists wear and tear better than older blends. If you’ve worn running shoes or handled a toothbrush that flexes without snapping, you’ve probably benefited from nylon 6,10. Hospitals and clinics go through piles of disposable gloves made with this same chemistry. People expect these items to be soft, strong, and comfortable, even if they never ask how it works.

People driving cars on a cold morning rarely connect that silent ease to sebacic acid. Gear oils, hydraulic fluids, and greases often include sebacic acid-based esters, which perform under enormous pressure and a range of temperatures. Modern vehicles rely on lubricants that don’t break down quickly and keep everything moving without clunky friction. Reliable lubricants keep repair bills under control and help reduce waste from mechanical failures.

Anyone who’s swallowed a pill that went down smoothly can thank the pharmaceutical industry’s trust in safe excipients. Sebacic acid supports slow-release pharmaceutical coatings that steadily release medicines into the body. The Food and Drug Administration recognizes the safety of this material for internal use. This isn’t a flashy breakthrough, but the steady science means fewer side effects and better results from long-term therapies.

Sebacic acid offers an alternative to petroleum-based chemicals. Farmers grow castor beans in India, Brazil, and China. This renewable source means less dependence on oil and a shorter, more flexible supply chain. Some automotive firms pick sebacic acid-derived polymers for car parts and interiors because these biobased plastics are friendlier to the planet.

Sourcing large quantities of castor oil faces its own hurdles—weather, market swings, and fair pay for growers all shape the supply chain. Farmers working with castor beans handle plants that can irritate skin, making safety gear and fair labor practices more important than most people realize.

Chemists keep searching for ways to make production cleaner and more efficient. Lowering the energy used in refining or reusing waste byproducts can trim costs and waste. Companies that put worker safety front and center and pay special attention to their environmental impact stand out—not just for their profits, but for their long-term contribution to healthier communities.

Looking beyond the chemistry textbook, sebacic acid shows up in work boots, IV tubes, the family car, and everyday pill bottles. The fact that this compound, with roots in castor oil farming, forms a link between global agriculture, clean manufacturing, and simple comforts at home, feels like the kind of progress worth paying attention to. Real value comes from sticking with materials that prove their worth—time and again—in the places that matter most.

Sebacic acid shows up in plenty of daily essentials, from lip balms to lotions and even nail polish. It’s a dicarboxylic acid, usually made from castor oil, so it feels familiar for anyone interested in greener ingredients. If you squint at the ingredient list on your moisturizer, you might spot it there, often as part of a longer compound name. The cosmetics world relies on it for a smooth feel and some useful chemical properties that help the final product stay together.

One big question hovers: is this stuff actually safe for your skin? Plenty of research points toward sebacic acid having a low chance of causing problems. The U.S. Food and Drug Administration (FDA) allows its use in certain indirect food applications, which tells you something about it not being particularly harsh. The Cosmetic Ingredient Review (CIR) Expert Panel reviewed it and similar materials and didn’t find any major issues with safe use in cosmetics.

Dermatologists often look at irritation and allergy potential. In this case, sebacic acid hasn’t raised many red flags in patch tests. Some lab studies show it does not easily penetrate the outer skin barrier, which lowers the risk of it reaching deeper tissue or the bloodstream. That’s a big deal for people with sensitive skin or allergy worries. Plus, cosmetic chemists have used it for years without widespread reports of trouble.

People trust their skincare to do no harm, so transparency matters. Brands need clear ingredient lists. While sebacic acid has a pretty good track record, not every skin type is the same. Some people may experience irritation from pretty much any acid—even ones labeled “gentle.” If redness or itching appears after trying a new product, it’s smart to patch test or talk to a dermatologist.

Quality control plays a huge role. Sometimes, trace impurities show up during manufacturing. If companies skimp on purification, those trace amounts can lead to unexpected problems—nothing to do with sebacic acid itself, just sloppy processing. Reputable brands know this and work with trusted suppliers, usually sharing more about their ingredient sources with curious consumers.

There hasn’t been a major wave of recalls or lawsuits connected to sebacic acid in personal care. Incidents are rare, so rare they hardly touch the radar, which matches the scientific outlook. Studies on the skin barrier and cell health suggest this acid does not accumulate in the body, and it gets processed quickly if it enters through skin contact. That stands in contrast with some longer-chain acids and silicones, which can take longer to break down or leave residues.

Many eco-conscious shoppers appreciate that sebacic acid grows from castor plants, not fossil fuels. Ingredient safety isn’t just about test tubes and labs—it’s linked to where ingredients start and how they’re used. Castor oil is well-known in wellness circles for being safe and sustainable. That helps support positive views of sebacic acid by association.

The industry can always do better for people with sensitive skin. Brands should continue funding research and posting full ingredient disclosures, especially for those with conditions like eczema or allergies. Consumer voices push companies toward safer preservative systems and more thorough safety checks, not just for the headline ingredients, but for every part of the formula. Listening to customer stories and medical experts—not just looking at lab data—helps make products safer and more pleasant for everyone.

Sebacic acid may not be a household name, but this organic compound plays a much bigger role than most people realize. It pops up in products like cosmetics, lubricants, and nylon, and its roots stretch back to renewables—often castor oil. Chemically speaking, sebacic acid follows the formula C10H18O4. To visualize it in its pure state, imagine a powdery solid that leans toward white, sometimes with a tinge of cream depending on purity and storage. The appearance might seem simple, yet this powder carries more influence than meets the eye.

Consistency in the look and feel of sebacic acid signals something important: purity. If you find granules clumping or a color hinting at something other than white, that signals either contamination or improper storage conditions. Several chemical industries care deeply about purity since contaminants can trip up production, cause breakdowns, or even influence product safety. As someone who’s tinkered in a college chemistry lab (often the source of squeaky lab stools and faint chemical whiffs), it becomes second nature to check color and texture before diving into experiments—because a yellowed chemical almost always turns into an unexpected headache.

The real clout of sebacic acid comes from its structure: ten carbon atoms arranged neat as a chain, carboxylic acid groups bookending both sides. This set-up puts it into the dicarboxylic acid family. These groups make sebacic acid reactive and flexible, so it bonds easily with other molecules. For this reason, it gets transformed into nylon-6,10, a plastic used in things like machine gears and brush bristles. That versatility attracts manufacturers who need strong, lightweight polymers. In the world of chemical formulas, C10H18O4 doesn’t just sit on paper—it spurs industry and innovation.

A large part of today’s sebacic acid starts off as castor oil seeds, usually harvested in India or China. That means a renewable plant—not petroleum—forms the backbone of an entire industrial chain. Using biobased sources cuts reliance on fossil fuels, supporting global efforts to sweep up the environmental mess that comes with oil-based chemicals. Some folks might argue that mass-scale production puts pressure on farmland and water, but the search for green feedstocks will keep driving improvements. Industry should encourage crop rotation practices that reduce environmental impact while meeting sebacic acid demand.

Researchers and professionals alike keep a watchful eye on sebacic acid quality. Storage plays a huge part in keeping its white color and powdery texture. Dampness or sunlight can turn quality raw materials into less predictable troublemakers. Strict adherence to quality checks prevents such slip-ups. Labs tend to rely on tried-and-true tests—melting point checks, spectrometry, or chromatography—to confirm that nothing funky made its way into the batch. Having worked on a few analytical chemistry projects, I can say the difference between a clean and a contaminated product often gets decided in those final few steps.

As demand for more sustainable products grows, the spotlight on sebacic acid will only intensify. Researchers look toward enhanced purification techniques and more energy-efficient production cycles. These approaches promise a cleaner product and fewer emissions along the way. For industries banking on renewable sourcing, partnering with farmers and developing rural supply chains can help foster economic growth that feels good for producers as well as planet.

Sebacic acid, despite its chemical-sounding name, starts its journey in a much less intimidating place: fields of castor plants. Farmers cultivate these resilient crops in India, Brazil, and China, where the climate encourages tough green pods to yield castor beans. My own garden couldn’t pull off such a feat—these beans aren’t forgiving or suburban—but many rural families in India consider castor fields a generational story.

Deep down, castor oil sits packed with a molecule called ricinoleic acid. This isn’t just a nice-sounding scientific word. It’s the reason castor oil ends up in so many products, from lubricants to those ancient, childhood remedies our parents forced on us when we got sick. Factories soak, press, and treat the beans just to draw out this oil, setting the stage for manufacturing sebacic acid.

Extracting ricinoleic acid sets the clock ticking on a series of chemical reactions. There’s no magic wand; just heat, pressure, steam, and some careful use of chemicals. Manufacturers combine the castor oil with caustic soda, then break down the structure through processes called saponification and cracking. Steam and pressure rip open the long molecules until, at the end, science hands us sebacic acid. No one can claim this sequence is glamorous—it smells strong and leaves plenty of waste behind.

During my years researching sustainable materials, the environmental cost of these steps kept coming up. Factories churn out byproducts such as glycerin and yet another acid, which often builds up unless reused creatively. Some producers, eager to reduce their waste footprint, recycle these leftovers as fertilizers or industrial inputs. The results look promising, though many factories in developing countries lag behind in cleanup and emission control.

Few people know that this acid acts as the backbone for making nylon, certain plastics, cosmetics, and even medicines. Companies depend on it to produce bristles for toothbrushes, flexible hoses, and lightweight automobile parts. Walk through any supermarket, and you’re probably handling something that started off as a castor bean.

Global demand for biobased products is surging, and sebacic acid fits the bill. Made from castor oil instead of petroleum, it promises a lower carbon footprint. This doesn’t mean production is clean everywhere. Some regions keep up with regulations, treat wastewater, and install filters—others don’t. Communities living near plants that cut corners face polluted water and thick air. I met workers in Gujarat who worry about the caustic runoff affecting their fields, a story echoed in manufacturing towns worldwide.

Better oversight needs to reach both farmers and factories. If buyers make clear they only want acid produced with traceable, responsible farming and safe waste handling, more companies will feel pressure to act. Nonprofits have pushed for certification programs—the kind that track the beans, score factories, and audit waste streams. Some big chemical companies have already enrolled, and results show healthier communities and less environmental damage.

Switching to green chemistry—using enzymes, milder conditions, and fewer harsh chemicals—could trim pollution even more. Right now, researchers keep tinkering in labs, looking for affordable ways to scale up these breakthroughs. Strong demand for cleaner products, support for farmers growing castor beans sustainably, and factory upgrades all play a part in changing the story.

Sebacic acid may look like just another white powder, but the path from field to factory tells a much deeper story about how supply chains affect everyday lives.

Sebacic acid, that reliable dicarboxylic acid with plenty of industrial uses, ends up travelling the globe in all sorts of packages. I’ve worked with teams in both the specialty chemicals and plastics industries, so I’ve seen how the way you ship, store, and handle a powder like sebacic acid actually shapes workflows for everyone from the production manager to the janitor. A company that overlooks packaging details often runs up bigger headaches than it bargained for.

Paper or plastic bags dominate the daily grind. Think of the 25kg paper sacks you’ll see stacked neatly at chemical warehouses, double or triple layered to blunt moisture and resist punctures. Manufacturers often seal the whole lot in polyethylene liners within those sacks. Nobody wants to deal with spilled acid powder, and a busted bag costs more than just downtime—fine sebacic acid dust can trigger safety shutdowns and extra cleaning. Some operations favor full-on PE woven sacks, especially for long hauls or rougher environments.

Big difference comes down to how the acid will be used. Smaller plants may move bag after bag by hand, keeping things simple and nimble. Yet larger outfits swing toward handling forked pallets, shrink-wrapped for weather resistance. I’ve seen some buyers swear by vacuum-sealed or heat-sealed bags just to keep humidity out. A little moisture ruins a load fast—lumps, clumping, or even degradation are a real threat.

High-volume customers, like plasticizers or nylon makers, can’t waste time hauling sacks. Here, the industry turns to flexible intermediate bulk containers (FIBCs). These “big bags” or bulk sacks swallow up to a ton of material. Usually woven polypropylene, they’re rugged, stackable, and surprisingly nimble with forklifts. A lot of European buyers insist on dust-proof seams and extra liners. I remember one supplier cutting corners on liner thickness—result: lost an entire shipment to moisture creep during a rainy season.

For exports or truly massive quantities, steel drums or even fiber drums make an appearance. These drum options offer better protection from impact and weather but add to handling costs and require special equipment. Some resin makers order sebacic acid in special ISO tank containers—especially if the acid comes pre-dissolved or in suspension. This almost feels like a different world compared to bag and sack operations, where everything runs on a different scale.

People forget about what goes under and around those sacks. Untreated wood pallets rot or splinter, leaving mess and safety risks. A lot of European and North American operations now specify heat-treated pallets, even switching to plastic ones for easy cleaning and longer life. It’s the same story with labeling—certain customs checks now require tracking codes, bilingual warnings, and even QR codes. I’ve watched a missed label stall a full container for two extra weeks at Rotterdam.

Regulatory pressure has pushed some suppliers to drop unnecessary plastics or toxic inks in favor of more recyclable options. There’s also an increasing demand for return programs on FIBCs—clean and refill instead of trashing after a single use. Admittedly, change moves slowly in the chemical supply chain. A decade ago, almost no one questioned single-use plastic liners. Today, customers and regulators both ask tougher questions.

Sebacic acid’s journey depends more on packaging than most realize. Every bad packaging choice echoes all the way to plant floors, shipping docks, and even the customer’s risk profile. If you want a smooth operation, you’ve got to pick the package like it matters—because it really does.

| Names | |

| Preferred IUPAC name | decanedioic acid |

| Other names |

Decanedioic acid

1,8-Octanedicarboxylic acid Sebacinsäure NSC 407143 |

| Pronunciation | /sɪˈbæsɪk ˈæsɪd/ |

| Identifiers | |

| CAS Number | 111-20-6 |

| Beilstein Reference | 1208737 |

| ChEBI | CHEBI:28039 |

| ChEMBL | CHEMBL416 |

| ChemSpider | 6027 |

| DrugBank | DB02957 |

| ECHA InfoCard | The ECHA InfoCard of product Sebacic Acid is: **"03e9823c-d7aa-43ff-ae4e-4ccaf36a40be"** |

| EC Number | EC 204-673-3 |

| Gmelin Reference | 10536 |

| KEGG | C00487 |

| MeSH | D010141 |

| PubChem CID | 986 |

| RTECS number | VS7875000 |

| UNII | 6L9LL4VZ8H |

| UN number | UN1875 |

| Properties | |

| Chemical formula | C10H18O4 |

| Molar mass | 186.22 g/mol |

| Appearance | White powder |

| Odor | Odorless |

| Density | 1.21 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | 0.77 |

| Vapor pressure | 0.3 mmHg (at 160°C) |

| Acidity (pKa) | 4.72 |

| Basicity (pKb) | 2.90 |

| Magnetic susceptibility (χ) | -58.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.419 |

| Viscosity | 1.02 mPa·s (at 150°C) |

| Dipole moment | 1.15 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 202.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1271.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -5726.1 kJ/mol |

| Pharmacology | |

| ATC code | A16AX10 |

| Hazards | |

| GHS labelling | **GHS07, GHS08** |

| Pictograms | GHS07, GHS08 |

| Signal word | Warning |

| Hazard statements | H315, H319 |

| Precautionary statements | P264, P270, P280, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | 2-1-0 |

| Flash point | 230 °C |

| Autoignition temperature | 450 °C |

| Lethal dose or concentration | LD50 oral rat 18500 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral 16000 mg/kg |

| NIOSH | WA2625000 |

| PEL (Permissible) | PEL: 5 mg/m³ |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

Suberic acid

Azelaic acid Undecanedioic acid |