People have turned to glutaric acid for well over a century, stretching back to its earliest identification within the complex world of organic acids. Chemists in the 19th century drew fascination from the way it bridges the odd gap between smaller dicarboxylic acids and those with longer carbon chains. Its early preparations showed the potential of animal and plant tissues as feedstock, which fit the mindset of a time hungry for discovery. By the early 1900s, both laboratory and limited industrial syntheses flourished. Development roared to life by the middle of the twentieth century, with petrochemical routes granting reliable batches and the chance to engineer purity for laboratory standards and commercial demand. The need for nylon-type plastics and new pharmaceuticals, as well as improvements in analytical techniques, gave scientists plenty of reasons to dwell on the chemistry of glutaric acid and its relatives.

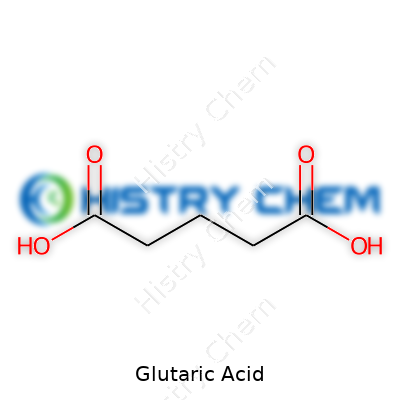

Glutaric acid stands out as a five-carbon dicarboxylic acid, a straightforward molecule that brings two carboxylic groups into striking proximity. Chemists recognize its importance as a building block in everything from pharmaceuticals and polymers to specialty resins and plasticizers. The powder usually lands in the laboratory highly pure—white, crystalline, bound for small runs of specialty compounds or as a calibration standard in analytical work. In industrial spaces, requests run from drumfuls for fixers and intermediates to tailored formulations for downstream synthesis. A glance at its most common packaging—HDPE drums, plastic jugs with product identification stamped clearly—reminds you that this acid straddles the chemical world’s boundary between commodity and specialty.

Glutaric acid rolls out as a colorless, crystalline powder, water-soluble enough to blend into a beaker without fuss. With a molecular formula of C5H8O4 and a molar mass of roughly 132.1 g/mol, it slots easily into reaction planning. The melting point hovers around 98 °C, making it easy to handle in most settings. In solution, its two carboxyl groups dissociate with ease, giving it a buffer range ideal for biochemistry, where stability counts. The pKa values roughly span 4.34 and 5.41, which lets glutaric acid play a flexible role in acid-base chemistry, especially where gradual titration is crucial. Its modest solubility in alcohols and organic solvents makes it appealing for a range of synthetic steps. The odor, slightly tart and sour, hints at its carboxylic origins.

Manufacturers typically guarantee a purity of no less than 99% for laboratory and pharmaceutical-grade batches, verified by HPLC or titrimetric standards. Moisture content, residual solvents, and heavy metal residues all sit within tight control—less than 0.1% for water, single-digit ppm levels for metals, and distinct limits laid out for organic residues tied to each synthetic route. Labels carry hazard pictograms in line with GHS, warning about skin and eye irritation. Shipping manifests follow DOT protocols for corrosives or irritants. Certificates of analysis trace each lot back to quality control data, with batch numbers, synthesis date, and expiration date front and center. Material safety data comes with readable instructions—no jargon, nothing hidden behind vague “see safety sheet” language.

Original small-scale labs relied on oxidation of related diols such as 1,5-pentanediol, using harsh oxidants like nitric acid under reflux—hard on glassware and the lungs. Today, glutaric acid often gets produced from cyclopentanone through ring-opening oxidation, letting process engineers tweak yields through catalyst selection and temperature control. Bio-based runs, though less common, use engineered microbial strains that digest simple sugars and excrete glutaric acid as a metabolic byproduct. Each method juggles trade-offs: cost, waste, energy consumption. Chemical engineers and biochemists track every variable, especially where high-throughput reactors are involved. Innovations in continuous flow chemistry mean process tweaks roll out fast, not as once-in-a-decade leaps but through small, steady improvements. What matters most is traceability, waste minimization, and reproducibility.

The two carboxyl groups make glutaric acid a capable team player in condensation reactions, especially in the hands of polymer chemists. Polyamides and polyesters with glutaric acid monomers feature in tough, flexible plastics—think fibers, insulators, and film coatings that shrug off moisture and resist cracking. Its reactivity with alcohols produces esters used as specialty plasticizers. In medicinal chemistry circles, attaching glutaric acid fragments to bioactive compounds helps tweak solubility or fine-tune metabolic stability. The acid anhydride, formed by gentle dehydration, serves as a powerful acylating agent for making advanced organic intermediates. In organic synthesis, the five-carbon backbone lends flexibility that short-chain acids just can’t muster, especially for branching off new substituents and fashioning cyclic compounds with custom properties.

Glutaric acid travels under a handful of aliases: Pentanedioic acid, 1,3-propanedicarboxylic acid, and in older chemistry texts, “dexylotic acid.” Commercial forms sometimes take on names from major suppliers, but regulations make sure the core chemical identity never gets lost. Globally, compliance with REACH, TSCA, and China’s chemical inventory keeps nomenclature consistent. The CAS number, 110-94-1, forms the linchpin for ordering, safety checks, and regulatory filings. Labels on drums or lab flasks usually repeat this info in bold, along with hazard classifications. In academic literature, “glutaric acid” dominates, but patent filings, safety sheets, and shipping manifests tend to add synonyms to avoid cross-border confusion.

In the laboratory or plant, gloves and eye protection cover the essentials. Direct skin contact may cause irritation, especially on broken skin, and the dust can tickle the airways if people get careless around open bags or while pouring. Eye washes and emergency showers should never sit far from benches or mixing tanks. Product labels reinforce strict handling: “avoid inhalation,” “store in cool, ventilated areas,” and “seal containers after use.” For waste, neutralizing with mild base before disposal is common practice, followed by thorough rinsing of vessels. Industrial storage focuses on preventing moisture uptake, since even small amounts of water can cause caking and trouble for downstream uses. Processors monitor air quality in large-scale manufacturing via sensors set to detect dust, vapor, or accidental releases, catching risks before workers get exposed. Suppliers train staff in spill response, containment, and medical actions, not as afterthoughts but as everyday habits.

Pharmaceutical developers harness glutaric acid as a synthetic intermediate, often grafting it onto core structures to improve pharmacokinetics or tune pH-dependent release. Engineers in the polymer sector dose it into plastics for improved flexibility and chemical resistance, while adhesives makers need its reactivity to anchor cross-linked matrices. In lab settings, biochemists reach for its buffering power, especially for enzymes or pH-sensitive reactions, where small shifts can wreck entire experiments. In the food industry, regulatory hurdles hold it back from widespread use, but specialty niches—like certain flavors or acidifiers—sometimes call on glutaric derivatives. Surface treatments for metals, cleaners, and water treatment chemicals fill orders for those who value mild but persistent acidity without too much corrosiveness. Paints, inks, and specialty coatings benefit from its potential to adjust viscosity and adhesion. Researchers experiment with glutaric acid as a precursor for biodegradable plastics—switching the mindset away from petroleum views toward more sustainable material streams.

Contemporary laboratories push glutaric acid beyond traditional boundaries. Biocatalysis teams design genetically modified microbes to ramp up yield, cut waste, and shrink the energy bill of large-scale production. Analytical chemists chart impurities and degradation paths in fine-grained detail, improving shelf life or qualifying the material for pharmaceuticals at stricter thresholds. Polymers research branches into new grades of polyesters and smart materials that respond to pH changes, with glutaric acid forming links that flex, twist, or dissolve under controlled cues. Medical researchers tinker with glutaric derivatives as prodrugs or diagnostic tags—chemistries that slip through cell membranes more readily than unmodified drugs. Wastewater engineers develop methods to strip glutaric acid from effluent streams, prevent bioaccumulation, and protect aquatic life from low-level but persistent exposure. Environmental scientists pursue life-cycle analysis, pressing suppliers to deliver certified low-carbon and renewable-sourced batches.

Studies show that glutaric acid, in the form typically encountered in the lab or factory, poses only mild acute threats. Skin and eye contact produce irritation, not deep burns. Inhalation of dust rarely leads to more than a scratchy throat—unless exposure becomes chronic or concentrated. The important research rises from rare cases like glutaric aciduria type I, a genetic disorder that causes glutaric acid to accumulate in the brain and disrupts neurological development. Toxicologists focus on this metabolic route, investigating how synthetic intake combines with natural pathways in animals and humans. Rodent studies at high doses suggest a low potential for carcinogenicity or reproductive harm, yet chronic ingestion remains poorly understood at the molecular level. Regulatory agencies keep reviewing new data, refining workplace exposure limits, and pushing for more transparency in long-term health tracking. Environmental risk assessments evaluate its persistence and any potential for negative effects on non-target organisms, keeping pressure on producers to reduce unauthorized releases.

Interest in glutaric acid keeps rising, mostly because its five-carbon backbone fits snugly in the push toward greener chemistry, biodegradable plastics, and bio-based intermediates. Synthetic biology stands ready to disrupt old-school petrochemical runs, promising bacteria or yeast that churn out glutaric acid under ambient temperatures instead of hazardous catalysts and high heat. Materials researchers work to fine-tune its role in smart polymers and controlled-release capsules—pushing deeper into medical technology, wearable sensors, and temporary implants. Advanced manufacturing calls for solvents, plasticizers, and additives with low toxicity and high performance, where glutaric acid derivatives get the nod. Environmental concerns weigh heavier, with emphasis on closed-loop systems, minimal-waste processing, and water purification solutions that break down glutaric residues quickly. As regulatory standards climb higher, the demand grows for clean-label ingredients, traceable supply chains, and rock-solid safety data. The agenda shifts from finding new uses to using smarter—balancing performance, sustainability, and long-term health impacts.

Growing up watching a parent work in a manufacturing lab, I learned to look past the complex names on chemical containers and see the real-world ways those compounds shape our lives. Glutaric acid is a molecule that doesn’t grab headlines but touches plenty of corners in daily routines. Found mostly as a raw material in industry, it rarely ends up on shelves at your local drugstore, but that doesn’t make it less valuable.

Factories across the world rely on glutaric acid to piece together products people use each day. You’ll find it at the base of plastic production, especially in the making of polyamides like nylon, which finds its way into clothes, carpets, fishing lines, and car parts. From personal experience touring a factory, I saw the focus placed on finding chemicals that can make stronger, lighter, more flexible products. Glutaric acid delivers that kind of performance, helping producers look for balance between strength and cost.

Its straightforward structure allows it to work as a key building block. Chemical teams, especially in the plastics and resins businesses, use it to get just the right flexibility and durability in end products. No one wants plastic gears that snap easily or shoes that break down too fast. Glutaric acid’s chain structure helps tackle those challenges.

Scientists in labs have also turned to glutaric acid when developing new pharmaceuticals. The path from raw material to medicine isn’t quick, but this acid can play a role during the creation of drugs meant to treat epilepsy and other neurological disorders. It acts as a starting point for designing compounds with targeted effects. By offering a reliable foundation, glutaric acid has found a place in the world’s search for more effective treatments.

Its importance isn’t confined to pills. Sometimes, researchers use it to create precursors for antibiotics or other specialty chemicals. My own brief time volunteering at a campus research lab taught me that building new drug compounds often begins with these surprisingly humble molecules.

This acid pops up in less obvious places. Some food flavorings rely on chemical relatives of glutaric acid for their tart or sour notes. Chemical companies sometimes use it for cleaning solvents, leather processing, or even making cosmetic ingredients soft and spreadable.

I have seen how workers in cleaning product plants appreciate raw materials that are both predictable and resilient—the supply chain disruptions of recent years made everyone more cautious, after all. Because glutaric acid comes from both chemical synthesis and can be produced through fermentation, it offers flexibility to producers wary of shortages.

There are challenges in handling and safety. Inhaling, ingesting, or coming into skin contact with glutaric acid can cause irritation or worse, requiring workers to suit up and use proper equipment. Regulation forms a buffer between industrial use and public harm, but mistakes can still happen. Investing in proper training and clear labeling matters. Companies can upgrade their monitoring systems or partner with reliable suppliers to boost safety and quality.

Demand for greener chemistry keeps growing. Bio-based glutaric acid, derived from renewable feedstocks, appeals to those aiming for cuts in carbon emissions. Supporting research into cleaner production methods and tightening waste management practices strengthens both public trust and ecosystem health.

Glutaric acid may not carry the familiar ring of table salt or baking soda, but it supports industries that thread through medicine, consumer goods, and more. Keeping a close eye on safety, sustainable sourcing, and responsible innovation ensures that its impact stays positive as needs change and grow.

Glutaric acid shows up in a lot of chemistry textbooks, but few folks would ever spot it in their daily routine. It’s a naturally-occurring compound, showing up in small amounts in the human body as part of normal metabolism. Chemists often use it in research and industry, but every so often, someone asks whether this compound belongs anywhere near their plate.

Regulators and food agencies never shy away from a tough question. They take a close look at every compound proposed for contact with food, and glutaric acid is no exception. The US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) have both gone through the research. Glutaric acid doesn’t have clearance as a food additive. Research teams usually focus more on its potential as a chemical building block rather than something to sprinkle on top of cereal or mix in for flavor.

Some forms of glutaric acid and its salts have cropped up in the animal feed industry, but that practice always stays within strict limits. Scientists weigh the benefits against safety risks. In animal studies, only controlled amounts are allowed. Large quantities haven’t been shown to benefit health or improve nutrition.

Glutaric acid works as a dicarboxylic acid. This isn’t a vitamin or mineral supplement, it’s a chemical intermediate. Too much glutaric acid inside a person’s system can cause trouble. Infants born with glutaric aciduria type 1, for example, can’t break down certain amino acids. Their bodies build up glutaric acid, which can cause brain damage. Even in folks without this rare genetic condition, dumping glutaric acid into the diet serves no proven purpose.

Lab studies also raise red flags. Large oral doses in animals have sometimes led to irritation, organ damage, or metabolic problems. Most reports on glutaric acid and safety address accidental exposure, not planned food use. There’s just not enough evidence to know how glutaric acid behaves over months or years if a person continued to consume it. Most food chemists encourage using ingredients with proven safety records instead of venturing into untested territory.

Thousands of food additives line grocery shelves or end up in packaged goods, but each one travels through a long road before approval lands. Back in graduate school, I spent more time than I’d care to admit in the toxicology library. One thing always stands out: unintended consequences lead to big regrets. Both consumers and food makers rely on a trustworthy system. Introducing new chemicals into the diet needs evidence and a record of safe use.

People today worry about toxins, allergens, and artificial additives more than ever. Parents look up E-numbers, debate synthetic flavors, and frown at new names in ingredient lists. Cutting corners with safety, especially for untested acids, shatters that confidence.

Instead of reaching for something like glutaric acid, established food acids like citric or ascorbic acid come vetted and widely accepted. These tried-and-true ingredients carry decades of food safety research behind them. Regulatory agencies and scientists keep a cautious eye on anything new and press for more research before changing the status quo.

For ingredient makers and anyone working in food science, supporting consumer health shouldn’t slip through the cracks for the sake of novelty or speed. Sticking with substances known to be safe serves everyone. The best approach always comes from asking tough questions and refusing to cut corners on evidence.

Glutaric acid crops up regularly in labs and production facilities, especially in the plastics and pharmaceutical sectors. What strikes most people handling it for the first time is its appearance—usually a white powder, easy enough on the eyes, but the real focus should fall on how it behaves behind closed doors. Storing this chemical calls for more than just tossing it on a random shelf and walking away.

Glutaric acid clings to water from the air. Those fine granules or powder grains soak up moisture quickly, which leads to lumpy clumps and eventually makes the substance useless in precise chemical reactions. The best way to preserve its quality is a tightly sealed container. I’ve seen plenty of wasted product simply because someone left a lid off overnight. Placing containers in a dedicated storage area with humidity control goes a long way. No one enjoys reordering bulk stock only to find it’s already turned brick-hard the next time it’s needed.

Glutaric acid stays stable at ordinary room temperature. It doesn’t melt at the slightest rise in heat, but that doesn’t mean the facility can ignore the storage room’s climate. Deskside windows, radiators, and poorly ventilated corners don’t make the best spots. Anything above 30°C starts to push limits. Direct sunlight isn’t a friend to most chemicals, and glutaric acid shares that sentiment. My colleagues learned the hard way when mild sun exposure gradually yellowed their sample bottles over the summer.

Chemical segregation isn’t just regulatory red tape; accidental mixing can create unwanted hazards. Glutaric acid reacts with strong oxidizers and bases. Everyday bleach, even in a spill, introduces a safety risk. Keep acids and bases on different shelves or cabinets. The bitter memory of one hurried intern combining incompatible waste streams serves as a strong reminder: label everything clearly, and double-check before relocating stock. If acids, bases, or anything reactive hide in the same room, keeping them apart is basic good practice.

Manufacturers usually send glutaric acid in polyethylene or tightly closed glass containers. Don’t swap those containers for anything that hasn’t seen a chemical compatibility chart. I once witnessed a batch ruined by someone moving it to a metal tin, leading to corrosion and contamination. Investing in good packaging upfront saves headaches—and wasted product—later. If transferring from one container to another, clean and dry the new one first. Cross-contamination spoils purity in subtle, costly ways.

Sloppy habits can make storage unsafe. Sweeping up spills, making sure every scoop and measuring cup is dry, and wiping down benches seems simple, but these basics prevent long-term storage issues. Log sheets and labels let users track how long a batch has sat in the storeroom. Any old supply deserves special attention: check for changes in color or texture before trusting it for production. Relying on proper inventory management avoids old, degraded powder fooling anyone into using compromised chemicals in a sensitive recipe.

Secure space, steady temperatures, careful packaging, and basic hygiene shield both people and the supply chain from unnecessary risk. Glutaric acid doesn't require elaborate technology to store properly, just knowledge built from experience and a steady routine. Every smart move saves money, keeps scientific projects on schedule, and guards against the kind of avoidable accidents that have no place in a well-run lab.

Glutaric acid doesn’t appear out of thin air. This five-carbon dicarboxylic acid starts its journey in the hands of chemists who have spent decades refining ways to make it both affordable and reliable. Most large-scale production draws on either biological or petrochemical routes. One common approach uses cyclopentanone, a simple building block in organic chemistry often derived from petroleum sources. Oxidizing cyclopentanone with air or oxygen, sometimes with a catalyst like cobalt, converts it into glutaric acid. Industrial plants favor this method because it gives good yield and fits smoothly into existing chemical infrastructure.

But there’s also a shift in the industry. As environmental concerns mount, more research dollars flow toward greener methods. Biotechnological routes harness microbes, tweaking their genetic instructions so they break down renewable feedstocks and churn out glutaric acid instead of their usual byproducts. As someone watching lab-scale fermenters bubble with activity, it’s impossible not to appreciate both the ingenuity and the patience demanded by this kind of work. A little yeast culture here, some metabolic engineering there — pretty soon, the conversation moves from petri dishes to discussions about tank farms and scalability.

Glutaric acid holds more significance than many realize. It helps create plastics and polyamides and serves a role in pharmaceuticals. Demand for specialty materials that help medical devices function safely and reliably keeps growing, and so does attention to how they’re made. Safety rules and public perceptions about pollution push companies to improve their processes constantly. Just last year, a report from the European Commission emphasized cutting down hazardous reagents. The traditional chemical oxidation path, while robust, carries a carbon and waste footprint that can’t get ignored.

Replacing or upgrading older methods needs more than lab success. Switching to a biotechnological route, for example, means dealing with the variability of biological systems, scaling up fermenters, and investing in downstream purification that won’t break the bank — trust me, anyone involved in process development can fill a pub with stories about “unexpected bugs” both literal and figurative. But the upside can be real. Glutaric acid derived from plant-based sugars rather than oil fits neatly into the circular bioeconomy governments and companies talk up at climate conferences.

Modernizing the synthesis of glutaric acid isn’t just about changing what happens in beakers; it’s about responding to bigger questions. Costs always matter in manufacturing, but the backdrop has changed. Regulators in regions like the EU and California push for cleaner chemical techniques. At the same time, customers along the supply chain care what’s behind the label. Collaborations between universities, startups, and established manufacturers bring change. One promising solution borrows from both worlds: hybrid processes that combine traditional chemistry with a late-stage biocatalytic step, giving the benefits of both routes while limiting downsides.

Glutaric acid production reflects a broader shift in how society thinks about molecules. Every step, from raw materials through purification, holds a chance for innovation. Watching these developments unfold up close, I’ve seen a field that listens increasingly to both environmental demands and practical concerns of the people running the plants. The process remains challenging, but rising to that challenge may make glutaric acid a quiet proof point for what sustainable chemistry looks like in practice.

You probably won’t find glutaric acid on the top shelf in your kitchen or under your bathroom sink. Still, this organic compound quietly plays a role in chemical labs, research spaces, and in some industrial processing. Chemistry students see it in organic synthesis, and manufacturers use it in creating plastics, resins, or pharmaceuticals. While it doesn’t trigger headlines like some notorious chemicals, ignoring its health risks carries real consequences.

Anyone who has worked with glutaric acid in a lab knows the sharp, upsetting smell if you get too close. Contact with the powder or solutions irritates the skin right away. Redness and an itch that does not quit signal you may have gone barehanded by accident. Eyes react even more strongly, so splashes cause immediate pain and can cloud vision for hours. Vapors sent flying through poor ventilation burn the throat and nose, making breathing an ordeal until you step outside. Asthma sufferers might find symptoms flaring up, and even the healthy struggle with coughing.

Chemical companies teach staff to avoid swallowing or inhaling fine particles. If glutaric acid gets inside the body—in significant amounts—trouble follows. It upsets the lining of the mouth, the stomach, and intestines. Folks unlucky enough to breathe dust daily face ongoing lung problems, including bronchitis or scarring.

I’ve heard experienced technicians swap stories about minor spills—nosebleeds, headaches, and the lingering taste in their mouths after careless handling. Emergency medical care sometimes becomes necessary; animal studies support the concern. Glutaric acid can spark inflammation inside tissues, with lasting effects if exposure never stops.

Factories must monitor wastewater carefully. Strong acids like glutaric acid damage aquatic environments in concentrations that seem small at first. If the chemical seeps into soil, it may disrupt microbe populations that keep fields healthy. In my own neighborhood, improper chemical dumping once led to a riverbank warning, barring kids from fishing or swimming. Most companies now follow disposal controls, but mistakes or leaks still happen. Local authorities—often stretched thin—can only address what gets reported in time.

I’ve seen labs run well and others cut corners. Gloves, face shields, and fume hoods work best when everyone uses them—and when stockrooms don’t run dry. Training fresh hires thoroughly closes more gaps than any sticker or warning sign. Clear spill protocols and visible emergency showers save hands and eyes when something gets knocked over. For everyone outside the lab, keeping factory drains blocked from stormwater inlets keeps accidental releases out of lakes or streams.

No single fix solves every hazard. Creating safer workplaces and a cleaner environment from chemicals like glutaric acid comes down to steady effort, smart rules, and fast responses to the slip-ups bound to happen. If you work anywhere near these compounds, speak up for stronger protections and check every label before you open up a new barrel or container.

| Names | |

| Preferred IUPAC name | pentanedioic acid |

| Other names |

1,3-Propanedicarboxylic acid

Pentanedioic acid Glutarate |

| Pronunciation | /ˈɡluː.tə.rɪk ˈæs.ɪd/ |

| Identifiers | |

| CAS Number | 110-94-1 |

| Beilstein Reference | 82673 |

| ChEBI | CHEBI:3099 |

| ChEMBL | CHEMBL16133 |

| ChemSpider | 570 |

| DrugBank | DB03851 |

| ECHA InfoCard | 100.007.826 |

| EC Number | 211-008-2 |

| Gmelin Reference | 60319 |

| KEGG | C00472 |

| MeSH | D005072 |

| PubChem CID | 7900 |

| RTECS number | MA8050000 |

| UNII | QTR25582JZ |

| UN number | UN3261 |

| CompTox Dashboard (EPA) | DTXSID1023704 |

| Properties | |

| Chemical formula | C5H8O4 |

| Molar mass | 132.115 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.42 g/cm³ |

| Solubility in water | Miscible |

| log P | -0.29 |

| Vapor pressure | < 0.1 mmHg (20 °C) |

| Acidity (pKa) | 4.34, 5.41 |

| Basicity (pKb) | pKb = 10.05 |

| Magnetic susceptibility (χ) | -46.4·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.434 |

| Viscosity | Viscosity: 2.00 mPa·s (20°C) |

| Dipole moment | 5.71 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 180.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -914.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2438.7 kJ/mol |

| Pharmacology | |

| ATC code | A16AX11 |

| Hazards | |

| GHS labelling | GHS07, GHS05 |

| Pictograms | GHS05, GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P264, P280, P305+P351+P338, P301+P312, P304+P340, P330, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 127.5 °C |

| Autoignition temperature | 430°C |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 oral rat 8190 mg/kg |

| LD50 (median dose) | 4300 mg/kg (Rat, oral) |

| NIOSH | GUU |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Glutaric Acid: Not established |

| REL (Recommended) | 5 kg |

| IDLH (Immediate danger) | No IDLH established. |

| Related compounds | |

| Related compounds |

Adipic acid

Succinic acid Pimelic acid Malonic acid Glutaric anhydride Glutaraldehyde 1,5-Pentanediol |