Once the foundation of modern chemistry rested on the skill of isolating organic acids and fiddling with alcohols, scientists stumbled upon the beauty of esters. In the late 19th century, researchers pushed further with large, even-numbered dicarboxylic acids. Suberic acid, hidden in the byproducts of natural oxidation or clever syntheses, captured attention among chemists, especially as cars and industrial machinery swept across Europe and the United States. The need for stable, well-behaved plasticizers and intermediates drove interest in esters of these acids. Dimethyl suberate remains something of a quiet success story from this era, surviving the shift from coal tar chemistry to the bright, precise work of modern labs. More than a relic, it is a legitimate building block that grew out of early organic synthesis, continuing its run even as approaches become cleaner and regulations stricter.

Run across dimethyl suberate in a warehouse and it rarely causes a stir. The compound presents as an ester derived from suberic acid and methanol. Industrial suppliers offer it as a colorless liquid with a faintly sweet scent, mild compared to sharper, more volatile relatives. You'll see its bottles branded under names like "octanedioic acid dimethyl ester" or “dimethyl suberanate,” traditions born from naming conventions built to simplify procurement and storage. The manufacturing world recognizes its structure for the balance between flexibility and rigidity—qualities well-suited in the production of polymers and specialty lubricants. Chemists value the ability to swap suberin linkages with minimal fuss or side reactions, so product developers can spend more time testing performance and less time troubleshooting supply chains.

Properties define application more than hope or price. Dimethyl suberate comes with a boiling point close to 260°C and gently melts above room temperature, settling somewhere around 15°C. It doesn't mix with water but relaxes easily into non-polar and moderately polar solvents, signaling promise for polymer blends, coatings, or fragrance fixes where movement across phases matters. Density dips below 1 g/cm³, keeping it lighter than water, which matters if tank storage and transport efficiency enter the picture. In my own lab years, there's a peace in knowing your solvents, plasticizers, or reactants won’t corrode containers or scare off safety regulators. Stability under oxygen and sunlight marks another plus: breakdown takes effort, so shelf-life and performance don’t surprise product managers halfway through a rollout.

Technical docs generally call for clarity—not just in physical appearance but in composition and purity. Industrial dimethyl suberate checks in at purities above 98%, with moisture content and acid values spelled out on any reputable certificate of analysis. Packaging, labeling, and UN shipping codes matter for safety and compliance, especially with regulations tightening across the EU, China, and North America. In my experience, firms that ignore, or fudge, these specs invite unnecessary problems: disrupted imports, insurance headaches, and avoidable risk during audits. That’s why buyers scan for clear labeling, full batch traceability, and paperwork that links back to each production lot regarding toxicity, composition, and even batch-level stability testing.

Reliable supply starts with sound chemistry. Commercial routes for dimethyl suberate take suberic acid—often produced by oxidizing cyclooctane, castor oil derivatives, or employing bio-based processes—and react it with excess methanol over an acid catalyst. Sulfuric acid maintains popularity, but newer facilities experiment with tungstated zirconia or even enzyme-based approaches for environmental reasons. Distillation follows, peeling off the finished ester, removing leftover acid, and recycling unreacted alcohol. Waste streams are treated or valorized—think new rules around European chemical plant discharge or U.S. Clean Water Act enforcement ramping up lately. Consistency above quantity forms the heart of modern manufacture, where an off-spec batch can exhaust time, damage relationships, or even sideline whole product lines.

As an ester, dimethyl suberate serves as a chemical chameleon—readily hydrolyzed to regenerate suberic acid, or opened up through transesterification to form new esters with different alcohols. I’ve watched teams use it as a masked acid, only to snap it open under basic or acidic conditions at a strategic step in a multistep process. It tolerates heat and moderate oxidizers but will yield under intense hydrolysis or reduction. The long, even-numbered carbon backbone sees plenty of action in cross-linking chemistry, polymerization efforts, or as a reagent for modifying natural polymers. The relative lack of branching minimizes side products, which anyone running reactions at scale can confirm matters far more to cost and waste than subtle theoretical yields.

The world of chemical sourcing breeds aliases. Dimethyl suberate pops up as "dimethyl octanedioate," "octanedioic acid, dimethyl ester," or less often as "suberic acid dimethyl ester." Each label caters to the comfort of local standards, legacy catalogs, or regulatory filings. Some will stick to Chemical Abstracts Service (CAS) numbers to sidestep the tangle of translations, but warehouse pickers or customs officials depend on labels matching the paperwork. Across different suppliers and regions, brands keep their own product codes for traceability, which allows quick verification during audits and protects against supply chain fraud—a growing concern as more suppliers enter globalized raw materials markets.

Safety teams prioritize clear hazard labeling and robust training because the industry has learned, sometimes through costly mistakes, that accidents follow oversight gaps or complacency. Although dimethyl suberate doesn’t possess acute toxicity or aggressive reactivity, long-term exposure studies matter, especially for workers exposed to production-scale volumes. Handling protocols require engineering controls to capture vapors during heated processing or filling, coupled with personal protective equipment and robust emergency spill procedures. Regulatory updates mandate thorough signal words and pictograms on even small-cap containers. Firms sticking to OSHA, REACH, and GHS labeling not only reduce citation risks, but also build trust with regulators, customers, and internal safety teams accustomed to constantly shifting compliance requirements.

Industries value dimethyl suberate for the role it plays in synthesizing specialty polyamides and polyester resins. It strengthens both flexibility and abrasion resistance in plasticizer packages for films, wires, and specialty coatings. Lubricant formulators use it to tailor viscosity in engine oils for temperature extremes. Perfume houses and flavor firms take advantage of its faint scent signature, seeking subtle esters that lend complexity at low dosage. Pharmaceutical teams sometimes reach for its backbone to build tailored prodrugs or controlled-release agents, appreciating its stability and easy hydrolysis under biological conditions. Market researchers note upticks in orders following demand spikes for eco-friendly packaging, bioplastics, and updated automotive fluids—evidence of how one molecule can echo technological and consumer shifts far outside the chemistry lab.

Lab teams and academics approach dimethyl suberate as a test bed for catalysis, green chemistry, and new polymer formulations. Research pushes toward bio-derived starting materials and milder reaction conditions to match industry’s pivot to sustainable sourcing. Teams experiment with enzymes or recyclable solid acids, even using water as a reaction solvent, to cut waste and energy costs. Intellectual property filings document a race to patent new uses, especially in the field of medical materials, biodegradable plastics, and advanced lubricants. Investment in custom derivatization highlights a move from commodity scale toward specialty applications, with the supporting technical literature growing thicker almost monthly as new uses and improved processes claim commercial potential.

Toxicologists keep a watchful eye on both acute and chronic effects of commonly handled intermediates. Dimethyl suberate, with its simple structure, rarely triggers concern at exposure levels seen in factories or labs, but pressure from NGOs and evolving regulatory science ensures ongoing scrutiny. Studies so far point to limited bioaccumulation and fairly rapid breakdown in biological systems, but scrutiny of downstream metabolites hasn't let up. New data tools and AI-driven structure-activity relationships pull in analogues for comparison, a far cry from the hunches and small datasets common a decade ago. This means that even as evidence shows low toxicity, firms take extra care in updating safety data sheets, especially for markets in California or the EU where standards can shift overnight after a burst of advocacy or a handful of new research papers.

As chemical manufacturing transitions toward greater sustainability, dimethyl suberate finds itself in an interesting spot. Demand for bio-based chemicals pushes both supply chain innovation and new synthetic biology platforms. Researchers play with fermentation techniques or enzymatic conversion of plant-based oils to yield suberic acid, which can shorten supply routes and cut the carbon footprint. Efforts are underway to expand its utility in biodegradable coatings and medical delivery vehicles, pushing boundaries that once limited diester chemistry to niche plasticizer or lubricants markets. If regulations tighten around persistent organic pollutants or fossil-fuel-derived feedstocks, you'll see industries scrambling for alternatives that match the thermal performance and processability already known for this ester. The future most likely belongs to those who integrate safer, greener production without losing sight of the unforgiving standards set by decades of industrial, pharmaceutical, and consumer product experience.

Dimethyl suberate is a chemical compound that might not pop up on most people’s radar, but a lot goes on behind the scenes with it. It belongs to the group of substances known as esters. This chemical brings together suberic acid and methanol, resulting in a clear liquid with a mild odor. It always amazes me how some of the most unassuming compounds end up having a hand in products everywhere. This one lands in several corners of daily life, even if its name doesn’t ring a bell to those outside chemistry circles.

Spend any time looking at what goes into perfumes, you’ll notice a long list of unfamiliar chemicals. Dimethyl suberate finds its way into many. Fragrance companies appreciate its mild scent that blends well without overpowering other ingredients. It acts as a fixative, helping a scent linger on the skin or fabric. For anyone chasing a signature scent that sticks around, this ester quietly makes it possible. Cosmetic creams and lotions often include dimethyl suberate for its emollient qualities. The silky-smooth texture you feel from certain skincare products? This chemical often pitches in, making those formulas more pleasant and effective.

The reach of dimethyl suberate goes further than perfume bottles and moisturizers. Take the plastics and coatings industries. Manufacturers use it as a plasticizer, softening rigid plastics and making them more workable. My experience working with materials scientists taught me how important small tweaks are in processing polymers—dimethyl suberate can turn a brittle plastic into something flexible enough for wires or medical tubing. Walking through a factory, you might spot employees blending chemicals like this to batch-up products most consumers take for granted.

You also see it used as a solvent for specialty applications, dissolving certain dyes and chemicals in ways water can’t manage. Laboratories lean on compounds like dimethyl suberate for its stable boiling point and low toxicity compared to some alternatives.

Handling chemicals in any setting comes with questions about health and safety. With dimethyl suberate, risk falls on the low side—no one wants to splash it in their eyes or inhale big amounts, but it doesn’t cause trouble in small quantities found in everyday products. That being said, more data helps everyone. Transparency reports from the European Chemicals Agency and the US Environmental Protection Agency hammer home the value of detailed safety sheets. They highlight how safe use comes down to good ventilation and basic protective equipment for workers in industrial settings.

Environmental impact stays a talking point. The compound itself breaks down in nature faster than some older industrial solvents. Still, strict rules around disposal and emissions fit with the broader move toward green chemistry. More companies want renewable sources and biodegradable options, so researchers keep exploring plant-based routes to produce esters like this.

There’s momentum in the chemical sector to develop even safer and cleaner ways to make essential compounds. Investing in greener precursors, smarter waste handling, or finding replacements with the same performance but from plant oils feeds that progress. For small labs and big corporations, following regulatory updates and consumer demand shapes future decisions. Dimethyl suberate quietly sticks around in the mix, doing its job, as more people push for a world where safer chemistry becomes everyone’s expectation—at home, in the factory, and out in the environment.

Chemicals always turn heads when safety comes up, and dimethyl suberate has started popping up in different workspaces. Factories, labs, and even some niche manufacturers work with this compound, often for its role in flavors, fragrances, or as an intermediate for more complex chemical ingredients. Anyone mixing, pouring, or even storing it will ask the same thing—how risky is this stuff, really?

Let’s get the facts out clearly. Dimethyl suberate, known in the industry for its mild scent and solvent properties, doesn’t usually jump out as a major health threat. The European Chemicals Agency and manufacturer datasheets both agree: it’s not flammable in its basic form, doesn’t pack the serious punch of some industrial acids, and isn’t classified as a carcinogen or strong irritant in most settings.

Even so, safe doesn’t mean you can toss it around like ordinary soap. Safety data sheets—those crucial guides on the shop floor—highlight potential skin and eye irritation. Inhalation in poorly ventilated areas may cause mild respiratory irritation. History tells us that workers face risks not from sudden, dramatic accidents, but slow, underestimated exposures over months or years. I’ve seen gloves ignored, only for someone to come away with dry, irritated hands day after day. Nobody pays attention to the “mild” warnings until small issues stack up.

Good practice beats any promise from a label or supplier. Labs and factories almost always require gloves, goggles, and lab coats—not because the risk is sky-high, but because risks add up. Splashing small bits can cause annoying rashes, especially for people with sensitive skin. Contaminated hands touch faces, lunch, phones. It’s not dramatic, but it leaves an impact.

Spills should be cleaned immediately, even if they seem minor. Disposable wipes, prompt clean-up, and keeping the area aired out stop bigger problems. Simple ventilation works wonders—open a window or kick on the extractor fan. My own time spent helping set up new chemical handling stations drove home how often safety gets shortchanged for speed. All it takes is one person in a hurry and one unmarked container.

Reliable guidance only comes from trusted scientific reviews and agency reports, not sales sheets or guesses from colleagues. The ECHA registration dossier sets exposure limits and recommends standard protective gear. The U.S. Environmental Protection Agency also puts out relevant advice for workplaces. These endorsements don’t just list problems—they outline sensible steps that most shops and labs already run with, like requiring PPE and proper training for anyone handling obscure chemicals.

Anyone using dimethyl suberate needs clear information, training, and gear that fits—not just PPE dumped in a corner. Supervisors who check in regularly and encourage people to speak up about minor symptoms foster a stronger safety culture. Reporting even mild irritation or strange smells lets small issues get solved before they snowball.

Managers and workers who communicate honestly and stay vigilant build safer spaces. Regular review of safety protocols, easy-to-read chemical labels, and a culture where speaking up is valued turns a set of boring routines into true protections. People having a say over their gear and practices leads to fewer skipped steps and less risk, and in my experience that keeps both nerves and hands intact.

Dimethyl suberate usually turns up as a clear, colorless liquid with a faint sweet odor. I’ve handled samples in the lab that have the same almost oily feel you get when handling other esters. It pours smoothly, doesn’t leave behind any residue, and light glints right through. At room temperature, it stays liquid, and unless you give it a real chill—down below -20°C—it isn’t going to solidify.

This ester boils at around 261 to 265°C and freezes at about -18°C. Water wants nothing to do with it. Try mixing a beaker of dimethyl suberate with water, and you’ll see them separate before your eyes. On the other hand, it takes to organic solvents—like ethanol, diethyl ether, or chloroform—without fuss. Those years I spent working with organic extractions taught me that solubility matters more than people think because it shapes safety practices and waste disposal.

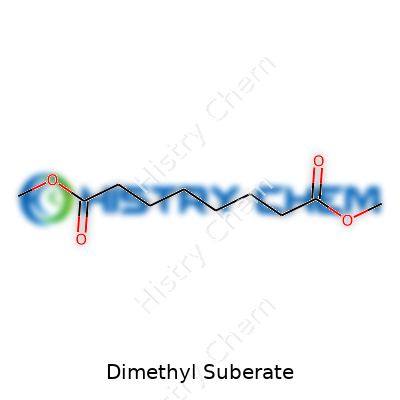

Chemically, dimethyl suberate’s formula is C10H18O4. Its structure features two methyl ester groups linked by a six-carbon aliphatic chain. In practical terms, this means it keeps fairly stable under normal conditions. You can store it in a regular glass bottle, away from heat and direct sunlight, and it won’t react with air or moisture the way more sensitive chemicals do. Typical reactions involve saponification—break it down with a base, and you’ll end up with suberic acid salts and methanol.

You won’t find dimethyl suberate raising alarms in most safety data sheets. Skin irritation can result from careless contact, especially if the liquid sits too long, and breathing in too much of its vapor isn’t a good idea in any lab. Fire risk stays low compared to many solvents, carrying a flash point near 110°C. I’ve noticed in workplace training sessions that materials like this get mistaken for ‘inert’ liquids too often, so I always push for gloves and good ventilation out of habit.

People often overlook properties like boiling point or solubility unless forced to troubleshoot a practical issue. My time helping with fragrance formulation proved that details matter—someone trying to blend dimethyl suberate needs to know it doesn’t dissolve in water or that it holds up under heat. Its unusually low odor and persistence under normal conditions help maintain scent compositions without breaking down over time.

Chemicals that resist easy breakdown, like dimethyl suberate, highlight the need for proper disposal. No one wants esters building up in soil or water, affecting wildlife. It’s important to lean on established chemical waste streams, and not just send expired stock down the drain or with the regular trash. Professional experiences taught me that clear labeling and regular staff training head off most problems before they start, especially in settings where bulk quantities get handled.

Labs and industry groups continue updating guidelines on handling chemicals like dimethyl suberate. Getting the little things right—storing containers tight, labeling everything clearly, ventilating workspaces—can save a lot of headaches. Facts about its behavior stem from published research and safety data, not rumor. Ongoing evaluation lets teams catch new developments or concerns as they arise instead of letting small issues balloon into real hazards.

People tend to overlook the simple things that keep hazardous chemicals from becoming a serious headache. In everyday work with dimethyl suberate, I’ve seen that even a mild solvent can create problems if ignored on the shelf or handled carelessly. This compound gives off a sweet smell, which fools some into thinking it’s harmless, but the guidelines for storing it are no joke. Too much complacency leads to preventable spills and headaches nobody wants.

Sturdy, tightly sealed containers matter far more than fancy labels and perfect shelving systems. If air and moisture sneak in, you’ll end up with degraded product and extra safety concerns. Ordinary glass or high-quality plastic bottles with screw tops do the trick. Make sure lids stay clean—any residue dries up and eventually weakens the seal. In some labs, folks use amber bottles as a habit from storing sensitive liquids. While this makes sense for light-sensitive compounds, dimethyl suberate stands up to light pretty well. Focus more on a good seal than on light protection.

Temperature makes a bigger difference than you might think. Hot storerooms boost internal pressure inside bottles, especially once summer hits. Dimethyl suberate may not catch fire easily at room temperature, but it still flashes at 130°C, so keeping the bottles cool is common sense. Refrigerated or air-conditioned chemical cabinets work, as long as no food stashes share the space. Avoid any spot near open flames or heat sources. In my own workspace, bottles always go onto the middle shelf of a well-ventilated cabinet, never shoved into hard-to-see corners or left on benches after a hectic day. Out of sight, out of mind doesn’t end well.

I’ve outright lost track of dimethyl suberate bottles in crowded storage rooms, only to find them months later mixed among bases and oxidizers. That’s just asking for trouble; accidental mixing can spell disaster. Acids, bases, oxidizers–they all belong elsewhere. An organized system helps staff stay on top of things. Color-coded shelving or bold hazard labels make it hard to miss where each bottle belongs. After cleaning up one too many sticky messes, nobody in my lab stacks supplies deep. One bottle per space, each visible and listed on a log, saves a ton of headaches if an emergency happens.

Regulations for storing chemicals sound daunting, but the basics come down to habit. I’ve watched new staff get lax with bottle handling only to face a minor leak. Old timers sometimes forget that even “mild” chemicals need respect. Good organizations run regular refresher briefings. They teach everyone—from junior technicians to the boss—what happens if storage slips. I’ve learned that it’s smart to post up-to-date safety sheets right where chemicals are stored, with diagrams and checklists people can actually use during their shift. Fewer missteps happen when staff understand why storage matters.

I’ve seen some labs lock up their solvents behind extra doors, install specialized ventilation systems, and add spill trays beneath every shelf. Those steps make sense if you’ve got lots of chemicals or tight regulations in play. For most situations, though, staying tidy, labeling well, and sticking to a daily storage check routine build a solid foundation. Missing even one of those steps could lead to ruined materials—or much worse. Responsible storage isn’t glamorous, but it means less stress for everyone and a safer workspace every day.

Dimethyl suberate pops up on the labels of plasticizers and flavorings and in labs that work with specialty chemicals. It’s made by combining suberic acid—a substance found in a few plant oils—with methanol. Folks who’ve worked in chemical plants or food research facilities might have come across its sharp, almost fruity odor. It’s a material built for function, not drama, often used in coatings, adhesives, and flavorings.

On paper, dimethyl suberate doesn’t wave red flags. It isn’t radioactive, doesn’t qualify as a heavy metal, and doesn’t stick around in the environment for hundreds of years like PCBs or PFAS. Looking into its molecules, this compound lands somewhere between low and medium persistence. Research shows many esters like it break down by reacting with water—hydrolysis—and bacteria in soil or water eat them up too.

That said, no chemical vanishes cleanly. Dimethyl suberate, if dumped in large quantities, could overwhelm wastewater systems. In one published study, ester chemicals showed reduced oxygen uptake in aquatic life when present in bulk. It’s not likely to cause a river to turn toxic overnight, but careless bulk spills could stress a wetland or a local stream, especially around a factory.

Working with raw chemicals brings its own worries. Bottles of dimethyl suberate, stored without proper seals, send fumes into the air. These fumes irritate eyes and skin. Extended exposure, especially without ventilation or gloves, wrecks comfort at work and leaves your lunch tasting funky. In my time shadowing an R&D technician, a leaking cap meant running outside, coughing for air. Training updates for the crew happened after that, focusing on containment and quick clean-up.

The hazards usually start and end behind closed doors. Waste handling becomes a domino effect issue: solvents need separating, leftover mixtures need treating. If these slip through—say an old drum dumped behind a small plant, or a drain never checked—it’s no longer just a safety training hiccup, but a community problem.

Published toxicology surveys, including those from the European Chemicals Agency, label dimethyl suberate as relatively low in acute toxicity to mammals and less bioaccumulative than common pesticides. Water fleas (Daphnia), common stand-ins for aquatic environmental studies, survive relatively high concentrations without dramatic population drops, though chronic exposure can add up.

So, compared to something like chlorinated solvents or flame retardants, dimethyl suberate isn’t setting off alarms. Still, absence of high-profile incidents doesn’t clear it of responsibility. Long-term, low-dose releases—drains, run-off, tiny leaks that add up—could pressure a watershed. Organic esters sometimes act as minor toxins in snail embryos and soil microfauna, signaling changes that take years to show up further up the food chain.

For users, manufacturers, or safety officers, common sense goes farther than high-tech solutions. Tighten up waste tracking, train teams to react fast, and push for simple solvent recovery rather than disposal. Support for green chemistry, such as swapping out hazardous feedstocks for more biodegradable choices, helps not just facilities but nearby communities.

Environmental testing shouldn’t just stop at what’s easy to see. Regularly sample local groundwater and sediment near storage or disposal points. If there’s one lesson from the chemical industry’s past, it’s that invisible damage shows itself slowly and can often be stopped with early action.

| Names | |

| Preferred IUPAC name | Dimethyl octanedioate |

| Other names |

Dimethyl octanedioate

Suberic acid dimethyl ester Suberic acid, dimethyl ester Dimethyl suberanedionate |

| Pronunciation | /daɪˈmiːθɪl ˈsuːbəreɪt/ |

| Identifiers | |

| CAS Number | Its CAS Number is '1732-09-8' |

| Beilstein Reference | 1207934 |

| ChEBI | CHEBI:89315 |

| ChEMBL | CHEMBL1501571 |

| ChemSpider | 73623 |

| DrugBank | DB14625 |

| ECHA InfoCard | 13f16aa2-1104-4046-b094-9e20ba4a0f4e |

| EC Number | 211-192-5 |

| Gmelin Reference | 8788 |

| KEGG | C16504 |

| MeSH | D008948 |

| PubChem CID | 10150 |

| RTECS number | VN6390000 |

| UNII | 0K1UUMA8GF |

| UN number | UN3272 |

| Properties | |

| Chemical formula | C10H18O4 |

| Molar mass | 258.33 g/mol |

| Appearance | Colourless liquid |

| Odor | Fruity |

| Density | 1.003 g/cm³ |

| Solubility in water | Insoluble |

| log P | 2.8 |

| Vapor pressure | 0.01 mmHg (25°C) |

| Acidity (pKa) | 13.1 |

| Basicity (pKb) | Product not basic |

| Magnetic susceptibility (χ) | -8.64 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4240 |

| Viscosity | 7.39 mPa·s (25 °C) |

| Dipole moment | 2.64 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 377.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -824.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4205.7 kJ/mol |

| Hazards | |

| Main hazards | May cause eye, skin, and respiratory irritation. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | Precautionary statements: P261, P264, P271, P272, P273, P280, P302+P352, P305+P351+P338, P312, P321, P332+P313, P362+P364, P501 |

| NFPA 704 (fire diamond) | 1-1-0-0 |

| Flash point | Flash point: 113 °C |

| Autoignition temperature | 237 °C |

| Lethal dose or concentration | LD50 (oral, rat): >5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): > 5000 mg/kg (rat, oral) |

| NIOSH | RN8200000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.5 mg/m3 |

| Related compounds | |

| Related compounds |

Dimethyl adipate

Dimethyl glutarate Dimethyl sebacate |