Diisopropyl sebacate joined industrial chemistry as synthetic needs branched out from the basics of lubricants and plastics. The world of esters exploded in the twentieth century, driven by a demand for safer, efficient plasticizers. Sebacic acid, a component from castor oil, turned into a hot commodity as folks searched for flexible, durable additives. Chemists bridged this acid with alcohols of various stripes, landing on isopropyl alcohol as a key partner—giving us diisopropyl sebacate. It served not only factories; medical device manufacturers and cosmetics brands found it ideal because it stood up to skin and environmental exposure. Companies in the global north and Asia pushed this molecule into more medical, personal care, and industrial products, showcasing how a once-obscure compound can impact everyday lives.

Diisopropyl sebacate stands out as a clear, colorless liquid, gentle in scent, and more agreeable for skin than earlier generations of plasticizers. Chemists working on cosmetic formulations use it for its slip, spreadability, and gentle touch. In labs and on factory floors, it acts as a plasticizer, emollient, and sometimes as a carrier for active ingredients in topical formulations. Its value comes not only from what it adds, but also from what it leaves behind: less skin irritation, low odor, and compatibility with a wide swath of formulation ingredients. Buying decisions often hinge on this safety and blendability, especially for major brands who cannot afford product recalls or customer complaints.

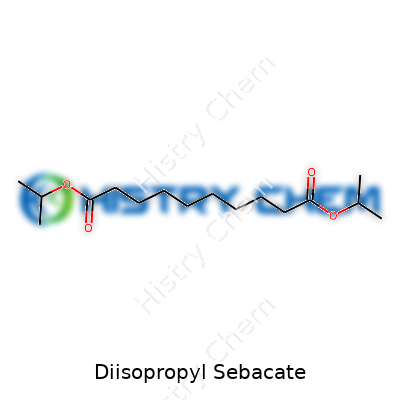

This ester comes with a relatively low viscosity, which gives products a smooth application without leaving a greasy residue. Its boiling point lands somewhere above 340°C—a testament to its stability under heat. In terms of solubility, it plays well with most organic solvents, but keeps its distance from water. Its molecular structure, a long ten-carbon chain with flanking isopropyl groups, prevents rapid breakdown, helping it last in tough settings like industrial lubricants or sunscreens laden with UV filters. The high purity often demanded in pharmaceutical or food-contact applications means consistent quality, verified batch after batch using gas chromatography or HPLC.

Product labels for diisopropyl sebacate carry more than just a name; they give buyers data on purity, color (usually measured by APHA standards), water content, acid value, and specific gravity. These specs matter in regulated markets. Brands selling finished products in Europe, North America, and major Asian economies rely on this detail to comply with REACH, FDA, or other national regulations. The chemical supplier ecosystem takes accurate, consistent labeling seriously because slip-ups threaten relationships with multinational buyers and disrupt supply chains. Bulk shipments usually land in steel drums or IBCs with barcoding and data sheets attached for traceability.

The main route to diisopropyl sebacate involves reacting sebacic acid with excess isopropyl alcohol under acidic catalysis—often sulfuric acid or paratoluenesulfonic acid. Industrial reactors heat the mixture to produce the ester and water, then distillation removes unreacted alcohol and by-products. Refinement steps polish the product, filtering impurities and fine-tuning color or odor. Scale matters: Small-batch cosmetic suppliers sometimes use glass reactors; major chemical firms move thousands of liters at a time through computer-controlled stainless systems. Stringent checks ensure that by-products stay below regulatory thresholds, because even parts-per-million problems can cause trouble in sensitive end uses.

On its own, diisopropyl sebacate resists breakdown, but chemists can coax new properties from it by hybridizing with other acids or alcohols. Hydrogenation, a common finish, bumps up stability further by saturating any stray bonds. Analytical teams use NMR or mass spectrometry to catch unintended side-reactions or impurities. Modification sometimes means tacking on functional groups that encourage greater compatibility with polymers, especially in specialty plastics or high-performance coatings. Technical service labs spend countless hours trialing blends, adjusting the backbone of the molecule to match operational needs for softness, weather-resistance, or lower migration rates in PVC.

Diisopropyl sebacate appears under various names in lab books and product catalogs. Synonyms like “Sebacic acid diisopropyl ester” or “DIS” appear in supplier datasheets. Major chemical suppliers give it trade names, sometimes pairing it with branding to suggest purity or safety for children’s toys or personal care products. These names matter to procurement officers and technical buyers, who need to match brand promises to regulatory filings or ingredient declarations. Chemtopia, Eastman, and other multinationals take time to build recognition around their grades, safeguarding against confusion in multi-lingual, multi-market environments.

Manufacturing and shipping diisopropyl sebacate happens under tight controls. Health and safety teams track exposure levels, ensuring the compound avoids skin sensitization or respiratory issues for workers. Global harmonized labels flag hazards—the material earns a “mild irritant” designation, mostly for the pure substance or concentrated vapors. Regulatory forces like OSHA in the US and ECHA in Europe scrutinize safety data sheets, pushing suppliers to test for longer-term health outcomes. Emergency teams drill spill responses, while manufacturing lines guard against static discharge or over-pressurization. The chemical’s escape into waterways brings close watching; spill kits, bunded storage, and wastewater monitoring come standard at responsible sites.

As a plasticizer, diisopropyl sebacate often enters flexible PVC, giving everything from wire insulation to synthetic leather its bend and resilience. In cosmetics, it forms the backbone for lotions, sunscreen creams, and deodorant sticks, where customers want a fast-absorbing, non-sticky feel. Pharmaceutical firms use it in capsules and topical drugs, counting on the low toxicity and skin-friendliness to pass regulatory muster. Industrial settings lean on it for specialty lubricants, anti-fog coatings, or hydraulic fluids—places that demand long service life without attack by common chemicals. Food-contact grades require even higher testing, with migration limits covered by strict government rules.

Innovation labs dive deep into tweaking the physical profile of diisopropyl sebacate. Teams work to enhance its interplay with bio-based plastics, pushing toward sustainability without losing reliability. Researchers also measure how it interacts with nanoparticles or new sunscreen actives, seeking stronger UV-blocking coatings that stay clear and stable outdoors. IP and patent teams watch for incremental advances—sometimes a new catalyst or blend brings performance gains worth guarding. Universities test it as a replacement for old, riskier phthalates, and industrial partners experiment with customized grades for medical textiles or controlled-release pharmaceutical applications. The market rewards suppliers who document advances with scientific rigor, supporting claims through peer-review, white papers, or regulatory filings.

Toxicologists evaluate diisopropyl sebacate with a long list of in vitro and in vivo models. Test results suggest low acute toxicity and minimal skin irritation, making it a favorite in personal care. Chronic exposure, reproductive toxicity, and carcinogenicity studies set the bar higher—long-term safety still drives caution, especially where products remain on the skin or close to wounds. Regulatory submissions call for repeated-exposure experiments at both high and low doses; labs publish results through agencies like the EPA, ECHA, or Japan’s Ministry of Health. Animal testing faces scrutiny, fueling more reliance on computer modeling or cell-culture studies. Formulators pay close attention to these findings, knowing today’s research shapes tomorrow’s supply contracts.

Diisopropyl sebacate holds a strong position in a world demanding safer, more durable additives. As regulators phase out older plasticizers and cosmetics giants turn toward cleaner labels, the product’s gentle profile promises more growth. The rise of plant-based starting materials nudges producers to develop renewable chemistry routes, while digitalization in manufacturing calls for tighter spec control and traceability. Emerging applications in green packaging, electronic device coatings, or even medical implants may drive the next round of investment. Companies riding the sustainable wave invest in green chemistry partnerships, publish their life-cycle data, and pursue high-profile eco-certifications. In an era of rapid product recalls and increasing scrutiny, it stands as a case study in how chemistry adapts to public health, climate, and market pressure—all at once.

Diisopropyl sebacate isn’t a name you’ll hear in daily conversation, but its effects matter to a lot more people than most realize. It’s a chemical that helps make things smoother, softer, and sometimes even safer. My first time reading about it came up during a question about why some sunscreens feel so clean on the skin compared to others. I learned that diisopropyl sebacate shows up in more bottles, sprays, and even medications than you’d guess.

If you ever rubbed in sunscreen on a hot summer day and noticed it glides on, dries down quickly, and doesn’t leave a sticky mess, there’s a good chance diisopropyl sebacate is a big reason. This chemical stands out as an emollient and solvent — basically, it helps create that sleek, easy-to-spread texture modern sunscreens often boast. It’s light, doesn’t clog pores much, and gives that “barely-there” finish people love. Some studies, like those from the Journal of Cosmetic Science, show that adding it to sunblock formulas drops the greasy after-feel. Not surprisingly, the skincare industry loves it.

Pharmaceutical companies rely on ingredients that help medication soak in where it’s needed most. Diisopropyl sebacate pops up here, too, mostly in topical formulations. It’s not the main active thing, but rather a carrier that moves the good stuff through your skin. According to research from the International Journal of Pharmaceutics, using it in ointments can boost absorption — that’s a huge deal for people counting on their treatment to work effectively.

It isn’t just about feeling smooth or spreading things evenly. Personal care and pharmaceutical companies need chemicals that don’t irritate skin or break down too quickly in sunlight. Diisopropyl sebacate fits this bill. Since it’s derived from sebacic acid, which comes from castor oil, its plant-based origin appeals to eco-conscious brands. Europe, the U.S., and many other places have tested it for safety over decades. Like anything, allergies can pop up, but pigment allergies or irritation are rare compared to other chemical additives.

Demand for cleaner, greener, and safer products keeps growing. The beauty and medical fields continue pushing for more natural ingredients, and diisopropyl sebacate already has a head start with its bio-based background. Some advocates still ask for more clarity about long-term safety, especially for children or those with skin conditions. I encourage pushing for more independent studies, open data sharing, and honest product labeling. The fewer the secrets, the fewer the headaches for people who just want a safe product that works.

Plenty of us search for products that feel good without mystery chemicals lurking. Checking for ingredients like diisopropyl sebacate gives shoppers a clearer sense of why a sunscreen or lotion works so well. As someone who relies on topical medications and prides myself on reading the fine print, I see the value in demanding safe, effective, and sustainably sourced ingredients in our everyday routines. That puts power back in the buyer’s hands and lets us make decisions rooted in real knowledge, not just flashy advertising.

Reading through the label on a new moisturizer or sunscreen often turns up some intimidating names. Diisopropyl Sebacate stands out for its scientific ring, yet this ingredient has been quietly smoothing lotions and cosmetics for decades. Investors in skin health have pointed to its role as an emollient, helping creams glide smoothly and lock in hydration. The ingredient’s reputation as a lightweight, non-greasy skin conditioner explains its surge in popularity, especially as brands respond to consumer demand for quick-absorbing, non-irritating products.

Many worry about unknowns in their beauty routines, especially after years of headlines linking certain chemicals to rashes or worse. Fortunately, the Cosmetic Ingredient Review (CIR) panel — an expert scientific committee respected in dermatology and toxicology — has evaluated Diisopropyl Sebacate for both safety and use. They didn’t find evidence pointing to allergic reactions, skin sensitization, or toxicity from topical use at levels found in cosmetics. European authorities and the US Food and Drug Administration both allow its use without special restrictions for personal care products.

Studies used by the CIR involved repeated applications on volunteers and did not turn up irritation even with concentrated exposure. Unlike ingredients that bioaccumulate or trigger hormonal effects, Diisopropyl Sebacate breaks down efficiently and leaves the body quickly. These facts address concerns about chronic exposure, especially for people who apply multiple products daily.

Despite its track record, every skin is unique. Individuals with extremely sensitive or compromised skin sometimes react unpredictably, even to ingredients that pass safety tests. In practice, I have met people who experience redness after using a new sunscreen or primer, despite all the right claims on the packaging. Patch tests remain the smartest step — dabbing a small amount on a clear patch of skin and waiting for a couple of days. In rare cases, a reaction could signal sensitivity to the specific formulation rather than Diisopropyl Sebacate itself.

Older concerns about ingredients’ effects on acne-prone skin have quieted over time. Clinical evidence and reviews by dermatologists generally place Diisopropyl Sebacate among the “non-comedogenic” options. It doesn’t clog pores for most people. Still, harsh winter weather or aggressive exfoliation can make the skin more reactive, so those prone to breakouts may want to track how their skin responds over time.

Choosing products means more than just looking for one “safe” ingredient. Personal experience and small-scale studies make clear that reactions often depend on a mix of ingredients, not just one. I recommend checking ingredient lists for fragrances or harsh preservatives if you have a history of irritation, as those cause trouble much more often than emollients like Diisopropyl Sebacate.

Transparency from brands, easy-to-read labels, and reliable third-party testing all help customers make choices. Websites like the Environmental Working Group and SkinSAFE collect consumer reports and scientific evidence to help buyers. I often guide friends and clients toward these tools. They help real people decide what to try based on their skin type and history, not just glossy advertising.

Every time a new ingredient hits the mainstream, so do new questions about long-term safety. Product safety depends on honest science, informed decisions, and paying attention to how your own skin responds. If Diisopropyl Sebacate shows up in your lotion, science suggests comfort and peace of mind for most folks. Anyone really worried or living with chronic skin issues should keep their dermatologist in the loop — because seeing your skin thrive always beats chasing trends.

Shoppers leaf through lotions and sunscreens, hunting for ingredients that sound pure or have roots traced to something growing in the ground. Diisopropyl sebacate shows up on many ingredient lists, from sunscreens to moisturizers. The question often pops up: Is it natural or synthetic? Like most things in personal care, the answer circles the way these products get made more than how companies market them.

Sebacic acid, forming the backbone for diisopropyl sebacate, comes from castor oil—a plant-based raw material. Factories convert castor oil through chemical processes, breaking it down and purifying out sebacic acid. The next step blends it with isopropyl alcohol, creating the final ester—diisopropyl sebacate.

Even though part of the material grows in the field, the finished product takes a detour through factories, chemical reactions, and strict controls. That means what ends up in lotion bottles doesn’t grow straight from a plant without human help. So, the typical bottle contains a synthetic ingredient, albeit one whose feedstock begins with something natural.

Consumers often check for natural sourcing to avoid irritation or allergic reactions. Real-world experience, plus clinical studies, show that naturally sourced ingredients can sometimes cause more skin issues than synthetic ones, depending on impurities. Synthetic versions, built under controlled settings, reach greater purity and safety for skin-contact products. Brands have leaned into this angle to promise better safety while still using substances related to nature.

The conversation also covers environmental effects. Growing castor plants uses resources, but modern chemical processing works toward less waste, lower emissions, and safer byproducts. Some manufacturers invest in greener chemistry, recycling solvents and capturing emissions. Synthetic chemistry doesn’t automatically mean heavy pollution now, and natural doesn’t always guarantee an eco-friendly label after you look at full life cycles.

Diisopropyl sebacate gives formulas that lightweight, non-greasy glide, making sunscreens and lotions more pleasant. Some studies have looked at its safety, finding it doesn’t linger in the body or cause major irritation. Honest labeling and transparency form the root of consumer trust: nobody likes being misled by overly floral marketing or claims that stretch the truth about “all natural.”

I’ve run into smaller brands touting 100% natural everything, only to dig deep and find the subtle line between starting materials and what’s actually in the jar. Diisopropyl sebacate stands out as a reminder that buzzwords sell, but facts matter more.

Consumers want choices. Some prefer botanicals and raw plant extracts. Others chase products that rub in smoothly and absorb fast, regardless of whether the molecule began on a farm. Regulations already push for accurate ingredient labeling, but real trust comes from brands that answer questions about sourcing, processing, and impacts straight-up, without flowery language or hiding behind technicalities.

If you care about natural versus synthetic, look for certifications, trace the full supply chain, and ask tough questions. Companies worth supporting answer with clarity so you can decide if a moisturizer or sunscreen fits your values—ingredient by ingredient.

Diisopropyl sebacate pops up in a lot more products than most people notice. You often find it listed as an ingredient in sunscreens, lotions, creams, deodorants, and even in some household sprays. Manufacturers use it because it feels light, spreads easily, and helps other ingredients mix better. I’ve used sunscreens and lotions containing this chemical for years, and at first, its name didn’t stick out. For people with sensitive skin or allergies, those long-winded ingredient lists start to mean a lot.

People ask if diisopropyl sebacate can trigger skin allergies. Dermatology research and cosmetic safety reviews, including assessments from the Cosmetic Ingredient Review panel in the United States, describe it as low risk when applied to healthy, unbroken skin. Most folks can use products with it without any stinging, redness, or bumps. I’ve seen family and friends with sensitive or eczema-prone skin use sunscreen containing this chemical with no problem.

Even so, rare cases of contact dermatitis can happen. The skin might react with redness or itching. Patch tests in some medical case studies have shown reactions, but these are rare compared to more notorious irritants such as fragrances or certain preservatives. If you’ve ever had a reaction to personal care products, it’s not always easy to pinpoint the culprit without guidance from a dermatologist.

People with a strong history of allergies or with sensitive skin should keep an eye on how their skin responds when trying any new product—diisopropyl sebacate included. Sometimes a reaction isn’t about the main ingredient but about how it interacts with other chemicals in the formula. I once heard from a friend who thought she was allergic to a popular sunscreen, only to find the real problem was a fragrance blended into the mix—not the diisopropyl sebacate.

Mislabeling and lack of clarity in ingredient lists can complicate things. A study published in “Contact Dermatitis” pointed out that, while diisopropyl sebacate is generally non-sensitizing, its presence combined with other chemicals might have unpredictable effects. In my experience, simplicity is key for anyone who wants to avoid surprises. Single-ingredient patch tests help sort out which component causes trouble.

Anyone using cosmetic products, especially those with sensitive skin, should read labels closely. If a rash shows up after applying a new lotion or sunscreen, stop using it and consult a dermatologist. Patch testing is a useful tool. I ran my own test last year for another emollient and learned just how specific my triggers can be. Boards like the American Contact Dermatitis Society offer patch testing lists, which can be shared with doctors.

Doctors and allergists advise starting with new products in small amounts—one spot at a time—so reactions don’t spiral out of control. Avoiding products with a long laundry list of unknown chemicals reduces the odds of trouble. When in doubt, stick to established, well-reviewed brands that publish their safety data online. Trustworthy information and some trial and error protect skin and peace of mind.

Diisopropyl Sebacate does a lot of heavy lifting in skin and hair products, even though its name sounds more like something from a chemistry textbook than a bathroom shelf. Stepping away from the marketing gloss, one can see its real appeal lies in how it feels on the skin and the help it gives product formulas. In day-to-day life, nobody enjoys sticky lotions or greasy sunscreens. Being someone with oily skin, I’ve thrown away countless creams that leave me feeling even shinier by lunchtime. But products with this ingredient glide on without heaviness. That smooth, almost silky finish isn’t just luck—it’s this compound doing its job.

Cosmetic chemists look for ingredients that spread easily and don’t cause breakouts. Diisopropyl Sebacate earns its place because of these qualities. It delivers that easy-to-spread texture, giving a protective layer without clogging pores. Data from consumer studies, including those backed by the Personal Care Products Council, note that it outperforms heavier plant oils for quick absorption. As someone prone to acne, I notice fewer flare-ups when using sunscreens, serums, or even makeup removers that contain this ingredient.

Sunscreens often depend on how well active ingredients get distributed across the skin. If a filter sits in one spot, patches can burn and protection drops. Adding Diisopropyl Sebacate to sunscreen formulas helps these actives spread more evenly over the face and body. This little boost can make the difference in sun safety—a fact recognized by regulatory bodies across North America and Europe. Studies published in peer-reviewed cosmetic science journals show formulations with this emollient get more consistent UV-blocking, helping people avoid sunburns and long-term skin damage.

People with sensitive or allergy-prone skin always seem to read ingredient lists with a magnifying glass. The fewer fragrances and harsh additives, the better. Diisopropyl Sebacate rarely causes irritation. The Cosmetic Ingredient Review panel classifies it as safe, even for kids and folks with eczema. In households with small children and adults who struggle with rashes, it becomes a trusted staple. Having tested dozens of baby lotions over the years, I’ve found the ones using this ingredient consistently leave soft, soothed skin by the evening bath time.

Sustainability and environmental safety catch more attention each year. Diisopropyl Sebacate, derived from renewable sources such as plant-based sebacic acid, stands out in greener formulations. Companies already label products containing it as “biodegradable,” taking some of the guilt away from tossing empty bottles in the recycling. In a world where ingredient safety and traceability shape buying decisions, its long-standing use and cleared safety for skin contact help ease consumer worries. The shift toward this greener chemistry makes a strong case for continued use in cosmetics.

The future for Diisopropyl Sebacate in cosmetics looks solid. Some researchers point out new uses as demand for texture innovation grows—think cooling gels or lightweight creams for humid summers. Brands experimenting with less is more formulations keep reaching for this ingredient to cut down on fillers. For shoppers who want comfort and skin compatibility without the fuss, its presence on a label is a good sign.

| Names | |

| Preferred IUPAC name | Di(propan-2-yl) decanedioate |

| Other names |

DIS

Sebacic acid diisopropyl ester Bis(1-methylethyl) sebacate |

| Pronunciation | /daɪˌaɪ.səˈprəʊ.pɪl sɪˈbæ.keɪt/ |

| Identifiers | |

| CAS Number | 110-19-0 |

| 3D model (JSmol) | `3d:CC(C)COC(=O)CCCCCCCC(=O)OCC(C)C` |

| Beilstein Reference | 1206051 |

| ChEBI | CHEBI:90531 |

| ChEMBL | CHEMBL2078883 |

| ChemSpider | 12494 |

| DrugBank | DB11267 |

| ECHA InfoCard | 13c6c3db-efb1-44f6-b11a-44f001090b9d |

| EC Number | 203-782-2 |

| Gmelin Reference | 569545 |

| KEGG | C19227 |

| MeSH | D002940 |

| PubChem CID | 8907 |

| RTECS number | AF8750000 |

| UNII | R6U3YN85T4 |

| UN number | UN3082 |

| CompTox Dashboard (EPA) | EPA CompTox Dashboard: DTXSID2035836 |

| Properties | |

| Chemical formula | C18H34O4 |

| Molar mass | Then the molar mass of Diisopropyl Sebacate is **314.49 g/mol**. |

| Appearance | Colorless transparent liquid |

| Odor | Odorless |

| Density | 0.95 g/mL at 25 °C |

| Solubility in water | insoluble |

| log P | 3.13 |

| Vapor pressure | 0.01 mmHg (25°C) |

| Acidity (pKa) | pKa ≈ 25 (very weakly acidic, typical of ester alpha protons) |

| Magnetic susceptibility (χ) | -7.48·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.445–1.449 |

| Viscosity | 9.5 mPa·s (25 °C) |

| Dipole moment | 2.93 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 683.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -7827.8 kJ/mol |

| Pharmacology | |

| ATC code | D11AX16 |

| Hazards | |

| Main hazards | Causes serious eye irritation. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS08 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P280, P303+P361+P353, P370+P378 |

| NFPA 704 (fire diamond) | 1-1-0-0 |

| Flash point | 140°C |

| Autoignition temperature | 355 °C |

| Lethal dose or concentration | LD50 (oral, rat): > 5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral, rat: 64,000 mg/kg |

| NIOSH | Not Listed |

| PEL (Permissible) | No OSHA PEL established |

| REL (Recommended) | 50 mg/m³ |

| Related compounds | |

| Related compounds |

Sebacic acid

Diisopropyl adipate Dimethyl sebacate Dioctyl sebacate Diethyl sebacate |