People found practical uses for esters like diethyl sebacate back in the industrial surge of the early 20th century. Factories craved chemicals that could stretch polymers and serve as plasticizers, and chemists noticed the flexibility granted by diethyl sebacate’s long-chain backbone. Soldiers carried equipment made from improved polymers softened by this silky ester, and its role kept growing through wartime and peacetime shifts. As synthetic chemistry advanced, demand rose steadily, mostly from the plastics, fiber, and flavor industries. Several generations of researchers learned its synthesis as a rite of passage in the organic lab, guided by the search for reliable methods, cost savings, and less toxic inputs.

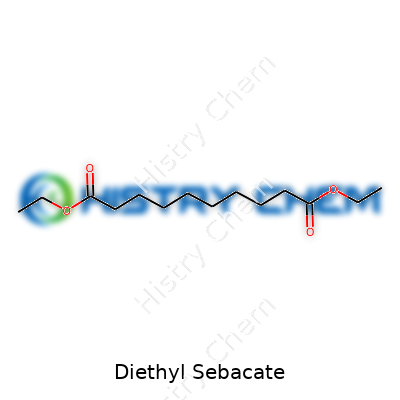

Diethyl sebacate appears as a clear, colorless, oily liquid that resists water. Its mild scent reminds some laboratory veterans of green apples, adding a slightly nostalgic touch. With a two-ester functional group connected by a ten-carbon chain, this molecule offers unusual flexibility. Manufacturers package it in drums or bulk tanks, labeling with safety details and purity level, because consistency matters for technical and safety reasons. Often, the fine chemicals sector sells it under the chemical name—diethyl sebacate—but it pops up in trade catalogs under names like diethyl decanedioate or sebacic acid diethyl ester.

A straightforward chemical formula—C14H26O4—tells a story of balance between hydrocarbon and oxygen-rich regions. Boiling comes around 298°C, and freezing sets in at minus 18°C, making this fluid hardy in extreme settings. It mixes well with alcohols and many common solvents, yet stays mostly aloof from water. Its refractive index, density, and low volatility turn it into a friendly ingredient for custom plastics and lubricants. The ten-carbon backbone gives it enough length to space out polymer chains without turning rubbery mixes brittle or sticky.

Suppliers list purity percentages, typically 99% or above, and caution about moisture. Standard labeling reflects guidelines set by health and environmental bodies: signal words, hazard pictograms, and first-aid steps. Packaging industries rely on tight sealing and checklists for confirmation of batch numbers and date of production. Buyers check certificates for phthalate content, residual acids, and ester content, since each affects the performance in sensitive gear or food-grade items.

Laboratories and factories produce diethyl sebacate through esterification, mixing sebacic acid (made from castor oil or adipic acid routes) with ethanol and a touch of acid catalyst, usually sulfuric. Skimming water drives the reaction to completion. Operators filter, distill, and wash it to high purity. Many companies switch to continuous flow reactors or greener catalysts like sulfonated resins to lower emissions and waste. Over the years, chemical engineers have pushed for better recovery of ethanol and recycling of byproducts, mostly to keep costs down and cut environmental impact.

This ester resists gentle conditions, but strong bases or acids chop it apart—hydrolysis snaps it back to sebacic acid and ethanol. Chemists can tweak the ethyl groups, swap out the acid backbone, or hook on other functionalities with heat and fancy reagents. Diethyl sebacate provides an anchor for graft polymerization or a reactant in specialty flavor and fragrance synthesis. Some projects rely on transesterification, swapping out ethyl groups for bulkier or custom-tailored alkyl chains, leading to new performance traits.

Markets and standards lists identify diethyl sebacate under synonyms such as sebacic acid diethyl ester, decanedioic acid diethyl ester, and the common abbreviation DES. It occasionally wears a trade name when used in niche fragrance or medical applications. Buyers in food or pharma fit it under regulatory codes referencing the same chemical backbone, avoiding confusion in supply chains.

While not acutely toxic at low exposure, operators always treat diethyl sebacate with respect. Gloves, goggles, and fume hoods remain the norm during lab and production work. Extended inhalation or skin contact can irritate, and accidental spills on hot surfaces demand prompt cleanup. Safety data sheets flag it as combustible and recommend keeping it away from open flames or oxidizers. Food and cosmetic sectors insist on tighter impurity checks and allergen testing before batch release. Regulatory shifts push producers to provide expanded environmental impact reports and worker training, and every step gets logged for traceability.

Industrial labs pour thousands of gallons of diethyl sebacate into polymerization tanks, chasing that elusive balance between safety, cost, and product strength. It acts as a dependable plasticizer for PVC, cellulose acetate, and specialty rubbers, keeping credit cards flexible, cable insulation smooth, and some synthetic leathers supple. In personal care, it slips into fragrances and sunscreen lotions, helping dissolve key ingredients and spreading scents evenly across skin. Diethyl sebacate serves as a carrier for flavorings—think green apple and berry—nestled within chewing gum or soft drinks, registered as GRAS (Generally Recognized as Safe) in the US when purity holds to food-grade standards. Pharmaceuticals benefit from its solvent powers, especially in soft gel capsules and topical ointments, and some insect repellent blends use it as an active carrier.

Universities and R&D labs keep returning to diethyl sebacate for new green chemistry projects. Biodegradable plastics research leans on its renewable origins, especially when processes start from plant-derived sebacic acid. Startups experiment with advanced recycling and zero-waste distillation, hoping to cut costs and environmental debts. Material scientists test whether swapping diethyl sebacate with related esters will create tougher, lighter, or more heat-resistant products, while biochemists scrutinize its role in drug delivery systems for emerging therapeutics. Flavors and fragrances research push it into volatile blends, expanding beyond historic apple and grape notes to sharper, modern scents. Electronic engineers in the flexible circuitry space dip test samples for next-generation insulation, hoping for lower leaching and higher thermal stability.

Older toxicity testing showed low risk in typical use, but new pressure grows to check breakdown products and chronic exposure. Environmental toxicologists measure how diethyl sebacate breaks down in soil and water, and metabolites in humans or animals, to spot any slow-release hazards or bioaccumulation. In most applications, it stays at concentrations far below thresholds for concern, though researchers stress the value of routine re-testing as production ramps up and regulations shift. Special teams in pharma and food research screen for allergic reactions, interactions, or long-term metabolic quirks, and public health officials watch for signals in consumer abuse cases. For bulk uses, emergency response crews drill for accidental spills, knowing that cleanup routines impact local waste streams and surrounding air and water quality.

Looking ahead, shifts in green chemistry and bioplastics may carve out bigger roles for diethyl sebacate from plant-derived feedstocks. Consumer brands keep testing bio-based plasticizers for children's goods and clean-label packaging, raising demand for tighter traceability. Automation and smart reactors stand to shrink production footprints, cut off-gassing, and save on energy. Pharmaceutical labs track its solubilizing power for a new generation of medicines with tricky delivery demands, and regulatory boards push for lower residual solvents and improved lifecycle analysis. Tech industries sizing up improved insulation and high-flex films may turn to diethyl sebacate for a balance of endurance, processability, and cost. All these changes depend on keeping safety, transparency, and sustainability front and center, making this once-humble ester more important than ever.

Diethyl sebacate pops up more often than most people expect. This colorless liquid doesn't shout out for attention, yet industries reach for it every day. Plastic manufacturers use diethyl sebacate to make plastics softer and easier to shape. For example, that flexible vinyl raincoat or soft tubing at the hospital may rely on this very ingredient. The ability to make plastics bend helps both toy makers and the automotive world alike.

People may not notice it, but diethyl sebacate also factors into personal care. Perfumes and skin creams include it thanks to its ability to blend other things smoothly together. My time in a small skincare lab showed me how important the right “carrier” is for getting a texture that spreads evenly. Diethyl sebacate absorbs quickly and doesn’t leave a heavy layer behind, making it a favorite in lightweight lotions.

Safety teams in labs and factories keep a close eye on the chemicals used near people. According to the U.S. Food and Drug Administration, diethyl sebacate earns approval for indirect contact with food and skin. This doesn’t mean any chemical is harmless—just that, in controlled amounts, safety checks back this use. Most reports through regulatory databases show that short-term, light skin exposure tends not to trigger irritation or allergic reactions.

Of course, too much of anything throws a system out of balance. Prolonged contact or inhaling high amounts can still cause discomfort. Keeping chemical use responsible forms the backbone of good industry practice, and storage areas need clear labels. Regular risk checks, with data from groups like the European Chemicals Agency, help companies keep workplace safety tight.

Scientists often need a reliable “solvent”—something to dissolve or carry another ingredient—when formulating medicine. Diethyl sebacate fits this need in pharmaceuticals. The World Health Organization and pharmaceutical publications mention it as a solvent and plasticizer in coating tablets and capsules. This helps pills keep their shape, while coatings last longer and stay tougher in harsh storage conditions.

Pesticide makers also tap diethyl sebacate because of its properties as a carrier. It allows the active ingredients to cover crops evenly, creating better coverage with less waste. Years working with an agriculture startup taught me how balance in formulation means better results for farmers, and ultimately, safer produce on the shelf.

Some industries pay close attention to potential impacts on health and the world around us. Plasticizers in general can build up in water and soil over time. By tracking new research and working with safer alternatives, manufacturing can keep up with environmental demands. A few companies recently switched to naturally-derived options or less persistent chemicals. This movement grows as public awareness sharpens.

The lesson shows up clear as day: understanding chemicals like diethyl sebacate, their uses, and their impact supports both safer products and a cleaner planet. Manufacturers, regulators, and everyday people share responsibility in making choices that work now and keep tomorrow in mind.

Diethyl Sebacate comes from sebacic acid, which often comes from castor oil. Manufacturers use it as a plasticizer, ingredient in cosmetics, and solvent. The clear liquid finds its way into perfumes, creams, and insect repellents. Some folks might recognize it as a softening agent, helping give lotions a smooth texture. Chemists like it because it works well with oily and watery ingredients.

Plenty of personal care products rely on diethyl sebacate. Skin lotions, sunscreens, conditioners, beard oils, and certain medical creams all tap into this ingredient. Companies use it for helping mix oils and water, giving creams that silky feeling, and making scents stick to skin. The fact that it spreads nicely and doesn’t clog pores also makes it popular for medical ointments.

Research on diethyl sebacate dates back several decades. Toxicologists and safety organizations such as the Cosmetic Ingredient Review (CIR) and European Chemicals Agency (ECHA) took a close look at its effects on skin. In most studies, scientists did not see much irritation, swelling, or allergic reactions—even after repeated application. In animals and humans, researchers found no evidence of cancer, birth defects, or hormone disruption from typical skin use.

One reason diethyl sebacate gets a green light: it has trouble soaking deep into the skin. It prefers to hang out on the surface, acting as a barrier more than a penetrator. For the average person spreading on a little lotion each day, there’s little evidence of health risks. The US Food and Drug Administration (FDA) also allows the ingredient in indirect food contact, so it pops up in packaging too.

Not everyone breezes through with zero issues. Someone with super reactive, eczema-prone, or broken skin may notice stinging or redness, especially with formulas that include other harsh chemicals. While rare, a handful of case reports have linked diethyl sebacate with irritant or allergic contact dermatitis. Anyone who reacts badly to new skin products should check labels and test a small patch before full use.

Scientists haven’t caught diethyl sebacate building up in the body or causing trouble for organs, so the ingredient isn’t seen as a high-priority toxin. Still, studies usually follow short-term or occasional use. Workers exposed to concentrated, large amounts—like in a lab or factory—face different risks and need protective gear, since heavy inhalation or ingestion could affect the gut or breathing.

It pays to know what sits inside beauty and skin-care routines. Long ingredient lists deserve a glance, especially for people with allergies or chronic skin conditions. Diethyl sebacate sometimes appears under “perfume” or “fragrance” umbrellas, so companies don’t always list it on front labels.

Reading up on each ingredient pays off. Groups like the Environmental Working Group (EWG) and CIR regularly update databases with cosmetic safety info. Dermatologists and pharmacists keep up with research, so ask a professional about worries with specific lotions or sprays.

Some lean toward “greener” or hypoallergenic products when shopping. Fragrance-free creams often drop solvents and softeners like diethyl sebacate. Brands with clear ingredient lists and allergy testing build more trust. If a product triggers itching or redness—diethyl sebacate or not—stop using it and try something simpler.

Plain language on labels, up-to-date research, and real-world patch testing matter most. Personal care companies need to listen when shoppers push back on foggy labels or swap stories about skin problems. Safety for the skin starts with awareness and honest communication between makers, regulators, and customers.

Diethyl Sebacate often turns up in labs, manufacturing plants, and even fragrance blending rooms. Manufacturers reach for it when producing plastics, resins, or flavors. With its clear liquid form and faint scent, it gives the impression of being harmless. It pays to remember, though, that substances like these become trouble when handled with carelessness. Even a mild compound can turn dangerous if someone leaves it open on a bench, close to a radiator, or under a glaring sunbeam.

Think about the last time a simple mistake turned your ordinary day sideways—like forgetting milk in the trunk for just a few hours. Diethyl Sebacate doesn’t spoil that fast, but it’s far from indestructible. I have seen containers start to sweat or form deposits inside within a year when workers skip basic precautions. Laboratory guidelines and technical sheets highlight the necessity to keep the liquid tightly sealed, as it doesn’t mix well with moisture or air. Even trace water in the atmosphere creeps in and kicks off a slow breakdown of the compound through a process called hydrolysis. That’s why chemical suppliers always recommend storing Diethyl Sebacate in a well-sealed container away from humidity.

Colleagues might sometimes shrug off temperature warnings if a solvent doesn’t freeze or boil easily. This relaxed attitude often leads to headaches later, especially in summer months when temperatures rise and direct sunlight streams through warehouse windows. Diethyl Sebacate prefers a cool, shaded environment—think 15 to 30°C. In one warehouse I worked in, a small bottle left by a sunlit windowed shelf started to yellow after three weeks. Not only does light encourage degradation, but heat warps the integrity of chemical containers. It’s no fun cleaning up leaks that could have been avoided by simply choosing a shaded spot.

This solvent carries a flashpoint in the 140°C range. While not flammable like gasoline, careless placement near heat vents, welding equipment, or even coffee makers sets up a real risk. Over time, vapors from the liquid collect at the base of storage rooms or around poorly ventilated shelves. I’ve read reports showing that these vapors can catch fire if an ignition source pops up, causing injury and financial loss. That’s one reason supervisors insist on marked, ventilated chemical storage spaces well away from any heat source.

Mixing chemicals out of curiosity, or storing incompatible products in the same area, sometimes happens in smaller labs lacking chemical hygiene training. Diethyl Sebacate stays stable with most organics but should not be near strong oxidizers, acids, or bases. I have seen ruined ingredient stocks and pitted shelving caused by accidental spills or vapor mixing. Smart storage means regular label checks and keeping oxidants and acids on a completely separate shelf.

Rules on chemical storage didn’t emerge from bureaucracy—they reflect decades worth of accident data. Regular safety training drives good habits, not just regulations. Real safeguards include double-checking every bottle cap and never assuming yesterday’s clean-up was enough. Personal experience shows that leaks, strange smells, or unexplained stains always mean something got ignored. Quick, shared inspections and reminders go further than written policies when building a responsible workplace.

Anyone working around Diethyl Sebacate benefits from a few core habits: keep containers shut, store in a cool, dark place, avoid sparks and heat, and don’t mix storage with reactive chemicals. It’s not just about compliance—it’s about making sure everyone leaves work in good health. Safe storage is a shared job. Getting it right reduces waste, cuts down on costly cleanup, and keeps peaceful sleep at night.

Anyone spending time in the world of chemicals, especially in pharmaceuticals or plastics, bumps into diethyl sebacate sooner or later. This clear, oily liquid often acts as a plasticizer or solvent. Its reputation in manufacturing circles comes from its ability to improve the flexibility of plastics and assist in distributing substances evenly in a mixture.

Solubility questions come up all the time, and for good reason. Talking about what dissolves in what can get complicated, but water is always the starting point. Diethyl sebacate, with its long carbon chain, just does not play well with water. The scientific answer says it: barely over 0.03 grams dissolve in every 100 milliliters of water at room temperature. If you’re measuring this out, you’ll see that’s very little. Drop some into a glass of water, and you'll spot the oil floating on top or forming little beads.

Most folks don’t worry about solubility unless it suddenly matters. For formulators in pharmaceuticals, food, or cosmetics, it matters every day. If a substance doesn’t dissolve, it tends to separate, which can ruin a batch or make a product lumpy or ineffective. Diethyl sebacate’s reluctance to mix with water means someone designing a water-based lotion won’t use it as a key ingredient. Skipping this detail can mean wasted resources, possible recalls, and disappointment down the line.

Sometimes the wrong choice of solvent leads to unstable medicines or ineffective personal care products. Regulatory agencies aren’t too forgiving, and with good reason. Drugs in particular demand predictable performance, and that starts with knowing how the ingredients behave in each other.

Not every chemical book or supplier’s website explains why a solvent acts the way it does. A simple rule: long, nonpolar (hydrocarbon) chunks—like in diethyl sebacate—don’t comfortably break apart and hide between water molecules. Reading the safety data sheet, and seeing words like “practically insoluble in water,” isn’t nitpicking. It avoids surprises in the lab, saves money, and keeps the wrong stuff from making its way into finished products.

Looking forward, formulation science keeps growing sharper. Making emulsions, or fine dispersions of oil in water, still calls for surfactants and the careful hand of chemists or engineers. Expect more companies to lean on newer tools and smarter ingredient databases that highlight solubility up front to guide the product design phase. Mistakes around solubility tend to cost less than they did decades ago—mainly thanks to improved documentation and more transparent communication between suppliers and users.

For anyone on the ground, reading a technical sheet or prepping a batch, staying cautious around solubility quirks pays off. Facts like the stubbornness of diethyl sebacate around water don’t just collect dust in books—they shape safer, better products for everyone.

Diethyl sebacate carries the chemical formula C14H26O4. This molecule belongs to the family of esters, specifically created by reacting sebacic acid with ethanol. In high school chemistry, I learned how such reactions work in a beaker, but plenty of folks use this substance outside of a lab setting every day.

Some might glance at that formula and wonder if it’s just another specialty chemical stuck in a science textbook. From what I’ve seen, diethyl sebacate shows up in a surprising number of products. It serves as a plasticizer for plastics, often finds its way into coatings and inks, and even pops up in fragrances and cosmetics. That’s not just trivia. People surround themselves with things made softer or more flexible thanks to this ester, and most never know it.

Stumbling onto this compound in an ingredients list once made me realize how deep chemistry reaches into daily life. Companies use diethyl sebacate to alter material properties—think plastics that feel nice but don’t crack or fragrance oils that last instead of evaporating too quickly. Insect repellent manufacturers sometimes lean on this ester as a carrier, helping the active repellent stick around longer on skin.

Reliable data matters. The U.S. National Library of Medicine’s PubChem database points to C14H26O4 as the correct formula. Chemists across global labs reference this source for confirming authenticity, and manufacturers must trust that formula before adding the compound to their product lines.

Transparency matters more than most people realize. Modern shoppers have started scanning product ingredients before making purchases, thanks to smartphones and a growing concern about what goes on or near their bodies. Regulations in many countries require chemicals like diethyl sebacate to appear honestly on labels. Mistakes in listing formulas or confusion about a compound’s identity erode trust and spark regulatory trouble.

I once met a friend who wanted to know why her favorite sunscreen suddenly smelled different and felt greasy. Turns out a minor switch in the ester used, which included a trade-off between price and performance, caused a chain reaction of customer complaints. Manufacturers can avoid these stumbles by sticking to established formulas and studying how even subtle changes impact the end product.

Science doesn’t stop at the classroom door. Researchers continue working with esters like diethyl sebacate, reviewing long-term environmental effects and tracking how they break down after use. The Environmental Protection Agency supports deeper analysis into these breakdown products, aiming to ensure that additives in consumer products don’t harm people or the planet.

Consumers push for cleaner, safer, and more environmentally friendly ingredients. That pressure leads companies to perform thorough reviews of every molecule in their supply chain. Diethyl sebacate, with its well-studied formula, sets an example. Openly sharing correct chemical information and supporting ongoing studies makes products safer today and lays the groundwork for better solutions in the future.

| Names | |

| Preferred IUPAC name | Diethyl decanedioate |

| Other names |

Sebacic acid diethyl ester

Diethyloctanedioate Sebacate diethyl DES Diethyl sebazate |

| Pronunciation | /daɪˌiːθəl sɪˈbeɪkət/ |

| Identifiers | |

| CAS Number | 110-40-7 |

| Beilstein Reference | 635144 |

| ChEBI | CHEBI:132978 |

| ChEMBL | CHEMBL3183659 |

| ChemSpider | 5083 |

| DrugBank | DB14060 |

| ECHA InfoCard | 100.003.436 |

| EC Number | 203-743-0 |

| Gmelin Reference | 8827 |

| KEGG | C14393 |

| MeSH | D02.241.081.700.700.700 |

| PubChem CID | 8047 |

| RTECS number | AF9275000 |

| UNII | 6F189S1M47 |

| UN number | UN2525 |

| Properties | |

| Chemical formula | C14H26O4 |

| Molar mass | Molar mass of Diethyl Sebacate is **258.37 g/mol** |

| Appearance | Colorless oily liquid |

| Odor | Odorless |

| Density | 0.98 g/cm³ |

| Solubility in water | Slightly soluble |

| log P | 3.47 |

| Vapor pressure | 0.03 mmHg (25 °C) |

| Acidity (pKa) | pKa ≈ 25 |

| Basicity (pKb) | 15.55 |

| Magnetic susceptibility (χ) | -7.44e-6 cm³/mol |

| Refractive index (nD) | 1.427 |

| Viscosity | 13.9 mPa·s (25 °C) |

| Dipole moment | 2.53 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 576.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -706.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -6712.6 kJ/mol |

| Hazards | |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | Precautionary statements: "P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P303+P361+P353, P304+P340, P305+P351+P338, P312, P337+P313, P403+P235, P405, P501 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | Flash point: 215 °F (102 °C) (Closed cup) |

| Autoignition temperature | 215 °C |

| Explosive limits | Explosive limits: 0.7–6.5% |

| Lethal dose or concentration | LD50 (oral, rat): 5630 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 8200 mg/kg |

| NIOSH | JQ8225000 |

| PEL (Permissible) | PEL: 5 mg/m3 |

| REL (Recommended) | 5 mg/m³ |

| Related compounds | |

| Related compounds |

Dimethyl sebacate

Dibutyl sebacate Disodium sebacate Sebacic acid |