2-Octanol made its entrance into scientific records back in the 1800s, part of a flurry of alcohol isolations that followed advances in distillation. Chemists at the time experimented with plant oils, and the linear eight-carbon backbone structure attracted attention for its unique fragrance and its oily nature. Over time, industrialization steered the conversation towards larger-scale synthesis as the demand for synthetic lubricants, solvents, and plasticizers climbed in the 20th century. Through World Wars and economic shifts, 2-Octanol’s production kept pace with the expanding scope of organic chemistry labs and factories, finding a spot not only in laboratories but in fields as diverse as cosmetics and agriculture.

2-Octanol, sometimes called octan-2-ol or sec-octyl alcohol, stands out for its colorless appearance and distinctive mild, almost fatty odor. Commercially available 2-Octanol fits into formulations for flavors, fragrances, and specialty chemicals. Its straight-chain structure and secondary alcohol group give it an edge for various modifications, contributing properties valued by manufacturers of coatings, detergents, and lubricants. Unlike shorter-chain alcohols, it brings a balance of volatility with a sturdier backbone that holds up in applications needing both solvency and a degree of stability.

The molecular formula, C8H18O, translates into a boiling point hovering around 179°C and a melting point near -38°C. With a relative density around 0.82-0.83 (at 20°C), 2-Octanol resists mixing with water but blends smoothly with most organic solvents. Its moderate vapor pressure and flash point above 80°C reflect why industries prefer it where both performance and safety matter. Reactivity centers on the secondary alcohol group, opening paths for oxidation, esterification, and etherification. Such chemistry paves the way for countless tailored applications, but also frames safety protocols due to flammability and potential health impacts.

Producers and suppliers focus on purity above 98 percent, measuring residual water, color, and absence of related impurities. Labels in line with international regulations flag hazards such as flammability and possible skin or eye irritation. Storage guidance emphasizes airtight containers, stable temperatures, and good ventilation. Globally harmonized system (GHS) labels highlight the need for protective gloves, eye protection, and clear first-aid instructions. All of these details remain front and center on technical data sheets, shaping procurement decisions in industries from pharmaceuticals to agrochemicals.

Industrial pathways to 2-Octanol usually start with fractional distillation and hydrogenation. Producers source feedstock like castor oil or further treat 1-octene using hydration over acidic catalysts. Hydrogenation of methyl octanoate, another common method, brings strong yields when paired with a suitable metal catalyst. Each route juggles cost, environmental footprint, and scalability, but the goal remains consistent: reliable delivery of high-purity product at volumes that serve the entire range from pilot labs to sprawling plants.

2-Octanol’s secondary hydroxyl lends itself well to versatile transformations. Oxidation leads to 2-octanone, a valuable intermediate for fragrances. Reacting the alcohol group with acids creates esters used as plasticizers or scents. Halogenation, sulfonation, and transesterification all expand its reach in further synthesis. Such reactivity also means analysts and technicians must control process parameters tightly, minimizing byproducts and ensuring consistent batch quality. Routine testing with gas chromatography and infrared spectroscopy allows fine-tuning at every stage.

Across catalogs and scientific literature, 2-Octanol appears as sec-octyl alcohol, octan-2-ol, octyl alcohol, and secondary octanol. Some trade formulations blend 2-Octanol with minor branched isomers, but labeling clearly separates these from the straight, secondary version. Regulatory registers list the product under CAS number 123-96-6. Distributors maintain databases mapping synonyms and regional naming conventions, helping buyers steer clear of cross-contamination or spec mix-ups.

Handling 2-Octanol requires attention to engineering controls, good personal protection, and close adherence to established safety guidelines. Skin contact can cause irritation, so gloves and full-length garments prevent accidental splashes. Splash goggles or face shields add a layer of defense in pilot and production settings. Good ventilation keeps airborne concentrations below exposure limits recommended by agencies like OSHA and NIOSH. Facilities installing vapor recovery and emergency showers make sure workers stay protected during routine operations or cleaning tasks. As with most organic solvents and alcohols, fire safety training ranks high, and operations document waste management practices for both regulator and internal audits.

Manufacturers rely on 2-Octanol in an impressive variety of final products. The flavor and fragrance sector values its subtle yet characterful scent, processing it for use in perfume bases, soaps, and detergents. Paints and coatings gain improved flow and leveling thanks to its solvency and compatibility. In agriculture, 2-Octanol forms a base for certain pesticides and synergists, helping enhance uptake and performance. Chemistry researchers take advantage of its reactivity for custom syntheses or as a building block in pharmaceutical intermediates. Even the mining industry looks to its frothing action in ore flotation, separating valuable minerals from waste rock.

Academic and industry labs keep pushing the boundaries of 2-Octanol chemistry. Innovators explore catalytic systems that drive greener, more cost-effective production. Others investigate the fine-tuning of downstream modifications, optimizing conditions for ester production, or specialty surfactant development. Regulatory changes around hazardous chemicals prompt a search for safer analogs or process upgrades, spurring collaborations between chemical engineers and safety scientists. Academic research uncovers new bio-based sources, such as enzymatic conversion routes, aiming at both sustainability and long-term supply security.

Toxicologists have studied 2-Octanol to map risks to workers, end-users, and the environment. Acute exposure at high doses can trigger central nervous system depression, headaches, or mild liver changes in animals. Chronic effects surface only at levels rarely found outside industrial mishaps. Studies in aquatic systems show moderate toxicity, prompting close control on releases into waterways. Regulatory bodies cap occupational exposure, balancing the need for production with worker safety. Toxicological testing continues, supported by advances in cell models and computational toxicology, refining hazard classification in response to new data.

Demand for bio-based and specialty chemicals points toward wider adoption of 2-Octanol in green chemistry applications. Producers invest in renewable feedstocks, aiming to set themselves apart from rivals relying on petrochemical sources. Downstream, new applications in pharmaceuticals, pesticides, and specialty coatings drive both volume and technical innovation. Automation and digital process control bolster product consistency, while advanced catalysis lowers emissions and energy use during manufacture. Shifting regulatory and consumer preferences for safer and more sustainable chemicals keep 2-Octanol’s long-term prospects positive, pushing the frontiers of both industrial practice and scientific exploration.

People don’t walk around talking about 2-Octanol, but it’s everywhere if you look close enough. I first ran into this stuff in an old automotive workshop, where it showed up as a component in coolants and brake fluids. At that point, it just seemed like another label among many. Turns out, its slippery quality and stable nature keep car engines happy, especially through temperature swings and heavy loads. Mechanics can spot the difference in performance when the right ingredients come into play, and 2-Octanol often plays an uncredited role in getting the job done well and safely.

Oil refineries and processing plants give 2-Octanol a place where it shines. It works as a defoamer, knocking down pesky foam that can slow up chemical reactions. In factories, foam makes messes. It can turn a perfectly scheduled production line into a sticky, unreliable wait. I watched my neighbor’s food processing plant grind to a halt until the right mix of antifoaming agents landed in their tanks. Quality antifoam formulas often count on substances like 2-Octanol to solve a problem that plain water can’t touch.

Head into the world of perfumes or everyday cleaning sprays, and 2-Octanol drifts in again. It’s valued for both its own scent—a bit earthy, a bit waxy—and how easily it dissolves with other fragrance components. In household products and air fresheners, this quality takes it from the lab shelf to the supermarket. That same blending ability helps in flavor production, especially in food extracts and syrups where one wrong note can ruin the final taste. Professional flavorists use it to stabilize delicate blends so that the lemon in your soft drink tastes zesty every single time.

Many folks working the land rely on 2-Octanol for its role as an emulsifier and wetting agent. It helps pesticides stick to plant leaves, instead of sliding off with the rain. Fields see better pest control and less wasted product when wetting agents keep everything in place. Farm workers need products that can keep up with tough environmental conditions, and 2-Octanol delivers results that matter to real people working long, hard days outdoors.

Any chemical used this widely deserves a closer look. Safety sheets point out skin and eye irritation for 2-Octanol without proper handling. It gets handled in closed environments and with personal protection around, not kitchen sinks. Environmental tests show it breaks down in air and soil under typical conditions, but wastewater streams from factories can carry it off course. Manufacturers and plants I’ve spoken to invest in containment and proper disposal, since nobody wins if chemical runoff causes problems for the next neighbor down the road. Spills and leaks should always meet swift cleanup procedures, enforced by strict regulations and regular audits.

Looking ahead, sustainable alternatives to traditional chemicals catch attention from all sides of the industry. Researchers run lab tests for greener synthesis routes that use less petroleum and introduce fewer byproducts. A few startups already experiment with bio-based methods, aiming to lower overall emissions during production. If the big chemical companies decide to roll out bio-sourced 2-Octanol in a big way, cost and quality have to match up with the synthetic versions. We all have a part to play, whether by supporting responsible manufacturers or pushing for better regulations, so chemicals like 2-Octanol keep providing practical value without unnecessary risk. That balance—between function and responsibility—guides change in every industry it touches.

Most people have never heard of 2-octanol, though it turns up in more places than expected. Used in flavorings, fragrances, and as a chemical intermediate, this colorless, oily liquid helps create scents in shampoos, flavors in foods, and even components for plasticizers and surfactants. Because of how it slips into daily products, questions about its safety deserve more attention, not just by scientists but by anyone who cares about what enters their home.

Breathing in 2-octanol vapor or letting it touch skin can bring irritation. Splash it in eyes and the pain becomes real right away. Lab studies in rodents show that it irritates skin, eyes, and lungs if mishandled or if concentrations rise above typical use levels in factories or labs. At the same time, acute toxicity sits on the low end compared to more dangerous industrial chemicals—high doses can make animals drowsy or bring about breathing trouble, but it takes quite a bit to reach those effects.

In my own work handling chemicals in the research lab, gloves, goggles, and good ventilation always made up the shield. Most places that handle 2-octanol enforce those same rules. Lab safety sheets rate it as an irritant, but not a carcinogen or mutagen. It doesn't get a spot on the notorious lists of chemicals banned for everyday consumers in the US or the EU.

Pouring 2-octanol down the drain won’t help nature. Studies show it's biodegradable, which means standard biological treatment in wastewater plants can break it down. On the other hand, dumping large quantities can hurt aquatic creatures, stressing fish and water insects. My time volunteering for river cleanups showed that even "mild" chemicals, when concentrated, knock river systems out of balance.

No chemical floats above risk. Dose, frequency, and the path of exposure tell the story. In routine consumer products, 2-octanol appears at such low levels that poisoning chances drop close to zero. The main hazards show up for folks who work in plants making fragrances, cleaning products, or specialty chemicals. Manufacturers must monitor the air, supply heavy-duty masks if vapor might build up, and keep safety showers working.

That said, allergic reactions call for special attention. A handful of people may develop rashes or asthma-like symptoms, mostly due to the substance intensifying existing sensitivities. I remember a coworker who developed a mild rash after a spill—he wore gloves but had a tiny cut and the liquid seeped in. A trip to the doctor, and the symptoms cleared up, but it drove home that even less-toxic substances can bother someone susceptible.

People gain real confidence with chemicals once they know the routines: not eating or drinking around open jars, washing hands after use, wearing protective gear, and following disposal guidelines. Labeling must stay prominent on storage tanks and bottles, and secure training creates fewer opportunities for accidents. Researchers and workers benefit from clear protocols, and companies who look after both human and environmental safety reap fewer fines, injuries, and lawsuits.

As long as 2-octanol finds its way into common products, keeping an eye on its risks will matter. Solutions don't demand panic—just respect, education, and preparation.

2-Octanol often comes up in labs and industrial products, but it rarely gets any mainstream spotlight. I remember walking through a local manufacturing plant while studying chemistry, noticing the sharp, slightly oily smell coming from various bottles on the shelf. It was 2-Octanol, a substance that plays a surprising number of roles. This colorless liquid tells an interesting story through its chemical structure.

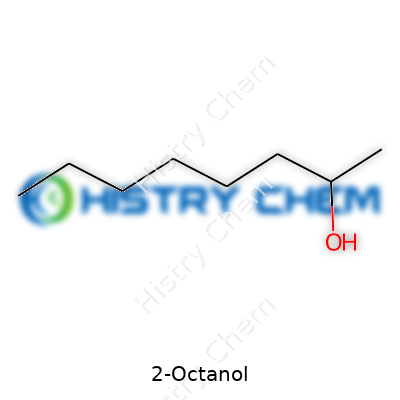

The backbone of 2-Octanol is a chain of eight carbon atoms, making it one of the higher alcohols. Chemists note it as CH3(CH2)5CHOHCH3, which means there’s a hydroxyl group (–OH) attached to the second carbon atom in that chain. This simple positioning changes the entire personality of the compound. Most people overlook this one structural difference, but the placement of the hydroxyl group makes 2-Octanol more soluble in water and more reactive than its cousins with the –OH group elsewhere.

Walking into any laboratory, tubes and bottles labeled with long chemical names fill the shelves. The formula for 2-Octanol, C8H18O, shows up often. It isn’t just a string of letters; it’s a hint at real-life applications where this molecule matters. The carbon backbone gives the molecule its strength and bulk, while the –OH group at the second carbon provides that slight polarity, nudging it to dissolve in certain solvents or break down under specific reactions.

The way a molecule is built often influences what it can do. 2-Octanol’s structure, especially the position of its functional group, gives it a unique edge in making flavors, fragrances, and even surfactants. I remember some food chemists talking about how even small differences in alcohol structure change aroma and taste. The way this eight-carbon chain bends and interacts determines why it pops up in perfumes and cleaning products.

Producers of plasticizers and lubricants also harness this structure. The slightly bulky but flexible nature of 2-Octanol lets it fit right into mixtures that need to soften plastics or improve the performance of engine oils. Chemically, it’s that secondary alcohol group that reacts differently than a primary one—offering options in further synthesis. Certain pharmaceuticals and pesticides begin their journey from this molecule. Research continues on using it as an intermediate, thanks to the ease of modifying the –OH group at the second position.

No chemical is totally without risk. I’ve worn my fair share of gloves and goggles handling alcohols like this. It absorbs through the skin and can irritate eyes and lungs. Safety standards from the CDC and OSHA call for well-ventilated spaces and protective gear. Industries improve their storage and handling practices to reduce accidents, and tech continues to push for better protective solutions as new applications emerge.

Petrochemical origins mean environmental worries always shadow production. I’ve followed some of the latest work in green chemistry and waste reduction. Some researchers now use bio-based pathways to make 2-Octanol, lowering fossil input and hazardous byproducts. This shift goes beyond the molecule itself; it defines how industries can move toward sustainable manufacturing while still meeting high technical demands.

The tale of 2-Octanol shows that even a modest tweak to a simple chemical framework can feed a whole range of markets. Whether mixing into a cleaning spray or blending into a new eco-friendly product, its structure remains central. Understanding the specifics of this molecule helps drive smarter choices in labs, factories, and down the supply chain.

2-Octanol looks pretty harmless on paper, but the stuff demands respect. This colorless to yellowish liquid gives off a strong odor and doesn’t mix happily with water, which hints at why storage matters. History in the industry, and more than a few close calls in labs and warehouses, show 2-Octanol won’t simply sit still. Left unchecked, its vapors escape easily, turning fire hazards into real threats. Many folks underestimate how just a little heat can send things sideways.

Old habits die hard. I’ve seen companies stash drums of 2-Octanol in places meant for engine oil. That’s asking for trouble. Experience tells me chemical storage thrives on isolation. Keep it away from heat sources and direct sunlight. Open flames and sparks spell disaster, so those storage areas demand clean, electrical-safe lighting and zero smoking anywhere nearby. In one warehouse, separating flammable organics by category helped the crew sleep better at night: fewer cross-reactions and fewer regulatory headaches.

Forget repurposed plastic barrels from the back of the yard. Reliable packaging calls for strong, sealed metal drums with labels that anyone can read at a glance. Some folks use high-grade polyethylene, but only if it’s meant for alcohol storage. Metal stands up to bumps and helps block out light. In any operation I’ve been part of, clean labeling saved the day during emergencies. Spill teams spot the right drum and tackle leaks with the right kit. It’s impressive how much chaos comes from a missing label or a flimsy lid.

Many experienced chemical handlers mention how crucial good airflow proves in close quarters. 2-Octanol’s fumes don’t need much of an excuse to build up, so a space with solid mechanical ventilation cuts down vapor levels and reduces fire risks instantly. Windows alone rarely handle the job. After an early mishap with fumes in a poorly-ventilated room, my crew never slacked off on keeping exhaust fans running and checked every few months. Breathing easy means storing the stuff with fresh air always in mind.

Accidents happen even with the best training. Anyone with hands-on chemical work will know the pain that comes from delayed cleanup. Direct contact with 2-Octanol irritates the skin and eyes, so gloves, goggles, and aprons always sit close to the drums. Good teams store spill kits nearby and hold drills for response time. An emergency shower in the storage area, not hidden in a hallway, long ago became standard, shaped by hearing too many stories of burns and rushed hospital visits.

Some companies try to skip regular checks and inspections. Over years of site visits and reviews, the best-run stories come from places logging every liter that moves. Entry logs, inventory sheets, clear procedures on how to handle and transfer 2-Octanol—all of these keep both staff and regulators happy. I’ve watched well-documented sites pass audit after audit, while those cutting corners get slammed with fines or worse, facility shutdowns.

No storage method survives long without honest training. People who work with chemicals remember lessons that stick—like handling drum leaks or reading MSDS sheets under pressure. Refresher sessions each year remind old hands and teach new workers why safety gear matters. The routines get boring, but boredom’s better than the stories you hear from folks who ignored just one glove or missed a crucial alarm. Smart companies invest in this. It’s cheaper than facing a spill—and safer, too.

The chemistry world throws a lot of alcohols at us. Among them, 2-Octanol stands out, not just because of its structure but because of its distinctive physical traits. If you’ve ever uncapped a bottle (which usually brings a mild, oily scent), you notice how it behaves differently compared to something like ethanol or propanol. The colorless, viscous liquid has a slippery feel and a boiling point that's both high and practical for certain industrial needs, roughly around 179°C. This matters when you’re using it in processes where low-volatility substances are safer or more practical.

People often overlook how slick, oily compounds like 2-Octanol blend with other materials. It doesn’t mingle easily with water, so you won’t see it dissolving in your tap anytime soon. Instead, it finds kinship with organic solvents like ether and chloroform. This selective solubility shapes where 2-Octanol fits: surfactants, lubricants, and fragrance carriers. Its octanol-water partition coefficient sheds light on its tendency to favor fats over water, signaling routes into living tissues and implications for environmental impact.

Aromatic but stable, 2-Octanol doesn’t flash off at room temperature. At about 85°C, it starts to give off enough vapor to catch flame, but its autoignition temperature sits well above what you’d find in daily settings. If you spend time in laboratories or factories, safety rules come from knowing points like this. Higher boiling points also cut down on respiratory risks during production and lower risk of accidental ignition in regular handling.

On the scale, 2-Octanol has a density close to 0.83 g/cm³ at room temperature—lighter than water, so any spill sees the liquid float, not mix. This floating behavior creates easy cleanup when used in controlled settings, but it also means that in the event of a release into the environment, contamination will hug water surfaces. Tracking movement after a spill turns into a manageable routine task, but failure to contain can create surface films that disrupt aquatic ecosystems.

It starts to freeze near -38°C, so you can count on it flowing even through chilly storage rooms. Colder temperatures don’t turn it into slush, unlike some oils. This melt point expands its usability in applications that demand liquidity, such as in lubricants or specialty coatings, and in places where unheated warehousing is standard. Regular oils harden in cold; 2-Octanol shrugs off winter like it’s another Tuesday.

Sustainable manufacturing calls attention to all steps in a chemical’s life, including its escape routes. 2-Octanol’s tendency to float and slowly evaporate puts responsibility on handlers to emphasize leak prevention. Facilities can invest in secondary containment—amenities as basic as catch pans or as advanced as automated shutoff valves—to minimize release. There’s no substitute for regular staff training or transparent incident reporting in keeping communities and waterways safe.

We spend a lot of time looking for substances that bridge the gap between industry and usability. 2-Octanol fits that mold. Its slick texture, high boiling point, and resistance to freezing make it a go-to for manufacturers needing flexibility without sacrificing safety or performance. Paying attention to features like density and solubility shapes responsible usage—a lesson echoed by environmental regulations worldwide. Knowing these details leads to smarter, safer, and more sustainable choices, both in industry and daily life.

| Names | |

| Preferred IUPAC name | octan-2-ol |

| Other names |

2-Hydroxyoctane

sec-Octyl alcohol Octan-2-ol Ethyl hexyl carbinol |

| Pronunciation | /tuː ˈɒktənɒl/ |

| Identifiers | |

| CAS Number | 123-96-6 |

| Beilstein Reference | 478022 |

| ChEBI | CHEBI:35697 |

| ChEMBL | CHEMBL15919 |

| ChemSpider | 7154 |

| DrugBank | DB14019 |

| ECHA InfoCard | 100.120.00 |

| EC Number | 01-2119471302-50-XXXX |

| Gmelin Reference | 1631763 |

| KEGG | C02328 |

| MeSH | D007245 |

| PubChem CID | 8097 |

| RTECS number | RH6950000 |

| UNII | 346E9E4P8T |

| UN number | UN 3082 |

| Properties | |

| Chemical formula | C8H18O |

| Molar mass | 130.228 g/mol |

| Appearance | Colorless liquid |

| Odor | characteristic;rosy |

| Density | 0.824 g/cm³ |

| Solubility in water | 1.1 g/L (20 °C) |

| log P | 2.9 |

| Vapor pressure | 0.022 mmHg (25°C) |

| Acidity (pKa) | 16.09 |

| Basicity (pKb) | 15.38 |

| Magnetic susceptibility (χ) | -7.05×10⁻⁶ |

| Refractive index (nD) | 1.419 |

| Viscosity | 13.1 mPa·s (25 °C) |

| Dipole moment | 2.33 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 296.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -393.7 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | –4786.7 kJ/mol |

| Pharmacology | |

| ATC code | V03AX23 |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS02,GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P210, P280, P301+P312, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 93 °C |

| Autoignition temperature | 410 °C |

| Explosive limits | 1.1% - 6.4% |

| Lethal dose or concentration | LD50 oral rat 2050 mg/kg |

| LD50 (median dose) | LD50 (median dose) of 2-Octanol: "3.3 g/kg (rat, oral) |

| NIOSH | NIOSH: SE3675000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of 2-Octanol: 50 ppm (skin) |

| REL (Recommended) | 50 ppm |

| IDLH (Immediate danger) | 500 ppm |