Looking back at the story of 1-Chlorododecane, the trail winds through the advances in organic chemistry starting from the twentieth century. Laboratories honed the art of producing straight-chain alkyl halides like this one, originally aiming to explore their reactivity for pharmaceuticals, agrichemicals, and surfactants. Early research often centered on short-chain analogs, but as chemical manufacturing grew, so did interest in compounds like dodecyl chloride. The rise of petrochemical industries led to ready access to lauryl alcohol and dodecane, setting the stage for larger-scale production. Over the years, 1-Chlorododecane served as a precursor for more complex molecules, especially in periods when specialty chemicals took center stage for coatings, personal care, and textile auxiliaries.

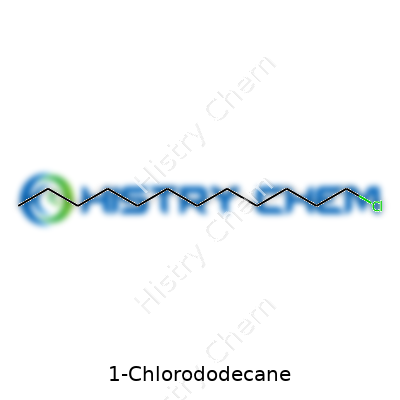

1-Chlorododecane belongs to the family of alkyl chlorides, with a linear twelve-carbon skeleton and a chlorine atom attached to the end. Its structure makes it more than just a laboratory curiosity — this molecule shows up in surfactant synthesis, specialty material formulations, and organic synthesis. Its reputation as a reactive intermediate stands out in fields where chain length and functional group placement really affect outcomes. Chemical suppliers commonly offer it as a clear liquid, and its uses cross boundaries from industrial labs to manufacturing floors.

This compound presents itself as a colorless to pale yellow liquid with a faint sweet odor that reminds chemists of other chlorinated hydrocarbons. Boiling point hovers around 263°C, and a melting point near -3°C keeps it nicely liquid at room temperature. It doesn't mix well with water, forming a separate layer due to its hydrophobic chain. Density lands at about 0.85 g/cm³. Chemically, it resists oxidation but reacts well in nucleophilic substitutions, thanks to the terminal chlorine. Many solvents dissolve it, which makes handling convenient in organic synthesis work.

Suppliers provide 1-Chlorododecane with purity levels often exceeding 96%, and the analytical details — like refractive index, water content, and acid value — get reported right on technical datasheets. Containers usually display precautionary symbols for flammable liquids and hazardous substances. Labels highlight the need for gloves and goggles during handling. Batch numbers, origin, and production dates also show up for traceability, while storage instructions stress cool, dry, and well-ventilated conditions to avoid decomposition.

Manufacturers rely on well-established pathways. Most commonly, lauryl alcohol reacts with hydrogen chloride gas or thionyl chloride under controlled conditions. The result? The hydroxyl group swaps out for a chlorine atom, forming 1-Chlorododecane. Efficiency depends on factors like temperature, molar ratios, and presence of catalysts such as zinc chloride. Careful drying and distillation remove impurities and side products. That approach helps meet the standards chemists demand for downstream applications.

1-Chlorododecane shines in substitution reactions, especially with nucleophiles such as amines, alkoxides, and thiols. Chemists use it to attach long alkyl chains onto diverse core molecules, creating everything from surface-active agents to phase-transfer catalysts. Reductive dechlorination gives dodecane, while oxidation can yield dodecanoic acid derivatives. Its chain length offers hydrophobic properties for modulating solubility in mixed formulations, and the chlorine opens doors for further functionalization. The chemistry textbooks fill with examples of these transformations.

Across catalogs and chemical inventories, 1-Chlorododecane shows up under different names: dodecyl chloride, lauryl chloride, 1-chlorododecane, and n-dodecyl chloride. Language changes, but chemical identity persists. These synonyms ensure that researchers and procurement teams find what they need, even if naming conventions shift from region to region.

Anyone working with 1-Chlorododecane needs to take its hazards seriously. Direct contact irritates skin and eyes, and the vapor can bother airways in unventilated spaces. Its flashpoint sits around 110°C, so open flames or sparks spell trouble. Labs and factories adopt strict protocols: splash-resistant goggles, nitrile gloves, and fume hoods. Workers receive regular training, emergency showers stand close by, and spill kits stay well-stocked. Waste disposal follows environmental rules — chlorinated organics never go down the drain.

The uses cover a lot: surfactant makers reach for 1-Chlorododecane to build cationic or nonionic surfactants, especially for textile processing and detergents. In the pharmaceutical sector, it extends carbon chains on drug candidates for improved absorption. Polymer chemists add it during the synthesis of specialty plastics that need particular flexibility or hydrophobicity. Oilfield services depend on its chemistry for mud additives, where wetting and dispersing properties make drilling smoother. Industrial researchers even explore its role as a phase-change material and lubricant base.

Academic labs investigate new reactions using 1-Chlorododecane as a test substrate, probing mechanisms in organometallic chemistry and catalysis. Industrial R&D teams tweak derivatives, targeting biodegradable surfactants and even green solvents. Computational chemists model its interactions to predict performance in blends or predict toxicity. Scientists keep sharing results through patents and journals, pushing boundaries with catalyst improvements and process intensification.

Studies focus on acute and chronic hazards: ingestion brings risk of central nervous system depression or liver stress, while chronic exposure links to dermatitis in industrial workers. Inhalation studies with rodents reveal dose-dependent toxicity. Environmental assessments show persistence due to the stable carbon-chlorine bond, with potential for bioaccumulation. Regulatory agencies monitor workplace air and skin exposure limits, and research presses on for better understanding of breakdown pathways once discharged.

Optimism runs high that greener synthetic routes and better waste treatment technologies will cut environmental impact. Biodegradable alternatives and lower-toxicity analogs emerge from ongoing research. The drive for sustainable chemistry propels work into using renewable feedstocks or recyclable catalysts. In specialty chemical markets, 1-Chlorododecane’s structure keeps it relevant for novel surfactants and advanced materials, but environmental scrutiny shapes the path forward. Industries adjust, scientists innovate, and regulations evolve to keep up. Personally, I’ve seen colleagues rework entire processes to fit evolving guidance, proving that chemistry never stands still — it adapts.

Most people never hear the name 1-chlorododecane outside of a chemistry lab. On the surface, it just sounds like another mouthful pulled from a material safety data sheet. Dig a little deeper and you find it’s a long-chain compound, lined up with a chlorine atom, showing up in more places than expected. Across my years handling chemical safety and talking with industrial workers, many ask if all these specialty chemicals really matter outside of factories. Yes, they do — especially ones like this.

1-chlorododecane sees steady action as an intermediate. That word basically means it’s a stepping stone, not the star player. Big chemical companies turn to it when crafting other ingredients, especially surfactants and lubricants. Surfactants hold cleaning products together. They pull the grease off dishes, lift the stain from your shirt, and help detergents rinse clean. This chain, with its chlorine addition, helps bind oil to water and kicks off certain reactions. Without it, the process slows down or costs more. I’ve seen facilities demand high-purity batches so the final product meets legal limits for quality and residue.

Its other main job: making lubricants tougher and more stable. Machine oils, coolants, and greases in heavy engines or cutting equipment last longer and run cooler when specialty additives come into play. These additives, including ones made from 1-chlorododecane, prevent wear and keep metal shavings from clogging machinery. Down at the auto garage or on assembly lines, reliability costs less downtime—and less money wasted on replacements.

Earlier in my career, I worked with hazardous materials teams, and one question always repeats: after manufacturing, where do these chemicals end up? If companies slip up, runoff or leaks from plants can send compounds like 1-chlorododecane into the water or soil. The chlorine atom makes it stickier and less likely to break down fast. Researchers warn that, at high doses, chlorinated hydrocarbons may cause nerve or liver issues, or harm local wildlife. Precautions at production and storage sites make the biggest difference, keeping chemicals secure and piping waste through cleaning systems before release.

In real-world settings, I’ve seen strict inventory controls cut risk. Constant monitoring and automated alarms help spot leaks fast, so any threat to health or environment stays low. Places I’ve visited train workers on safe transfer and spill response, using protective gear and air filtration. Tech has improved, but human focus is what keeps chemicals where they belong—out of water supplies, hands, and lungs.

Sustainable manufacturing pushes for greener solvents and additives each year, and folks in the industry are paying attention. There’s been a push for closed-loop systems where byproducts find a second life, re-entering production lines or being neutralized. Public reporting, waste audits, and real community engagement offer some of the best guardrails. Whether you’re in the lab, the factory, or the local water board, pressure for safer ingredients and better oversight grows. It’s possible to build products that work well and keep the rest of us protected. Each step, from the batch reactor to the bottle on the store shelf, adds up—and people are watching now more than ever.

Among the array of organic compounds available today, 1-chlorododecane grabs attention for chemists and those in industrial fields. This molecule has the chemical formula C12H25Cl. It’s a simple compound at first glance, but its uses reach beyond just an academic exercise. I came across it during a college lab practical, where we spent a whole afternoon trying to synthesize and characterize it. Anyone handling laboratory chemicals sees quickly how clarity about formulas and naming conventions makes life easier and safer.

Chemical names can sound intimidating, but there’s order behind them. The name “1-chlorododecane” breaks into “dodecane” – a straight, 12-carbon alkane chain, and “1-chloro” – a chlorine atom attached to the very first carbon. Organic chemistry classes make it clear: the main backbone provides structure, and the chloride at position one tweaks its behavior. The total number of hydrogen atoms drops by one from pure dodecane (which is C12H26) because a hydrogen leaves to make room for the chlorine.

Mistakes with chemical formulas can cause real trouble. A mix-up with a single carbon, hydrogen, or halogen changes how a substance acts in the world. For example, swapping the chlorine from the first to another position in dodecane makes an entirely different molecule. It’s like switching a bolt size when fixing a car—you can’t expect the same fit. I’ve seen mix-ups in student labs where a wrong formula led to incorrect risk assessments. That kind of mistake, on an industrial scale, risks wasted resources or even safety hazards.

Industries use 1-chlorododecane as a specialty chemical and in organic synthesis. It finds a place in surfactants, intermediates, and sometimes as a reference in research. The straight-chain structure means predictable reactivity, and a single chlorine atom on the chain helps further chemical modifications.

I remember seeing it as a reactant for producing other functionalized molecules. Organic synthesis often starts with something as straightforward as a haloalkane. The right starting material means better control over cost and purity, which keeps experiments clean and product development predictable. A mislabelled or misunderstood compound shows up in these bottlenecks and could impact everything from material properties to environmental fate.

To prevent errors, students and professionals should double-check formulas and practice drawing structures regularly. I keep a set of index cards with common compounds and their correct structures—this habit saved me plenty of headaches during undergrad studies.

Industries could improve workflows by broadening access to digital chemical databases. Technologies using quick structure-verification tools encourage fewer slipups in both research and manufacturing. It also helps to foster a culture where asking for clarification is standard, not a nuisance. Getting the formula right for a compound like 1-chlorododecane sets a solid foundation for safe and effective work, whether in a classroom or a production plant.

People working in the chemical industry have likely seen 1-chlorododecane show up in supply inventories. The substance appears as a clear, oily liquid and it falls into the family of organic chlorinated compounds. Manufacturers use it as a raw material in synthesis, and you might find it as an ingredient in lubricants, detergents, and a few specialty pesticides. Most folks never encounter it at home, but it’s a familiar presence in certain plants and laboratories.

Not all industrial chemicals demand panic, but taking 1-chlorododecane lightly can lead to trouble. Safety data sheets list it as an irritant—contact with skin may lead to redness or rashes, and splashes in the eyes burn. If you’re unlucky enough to breathe in its vapors, expect coughing, dizziness, or headaches. The smell may not warn you until it’s already floating in the air at a risky level.

Swallowing this liquid goes beyond a bad taste. People risk nausea, abdominal pain, or even vomiting. Animal studies show that high exposures might harm the liver and kidneys over time. It doesn’t qualify as a “major” carcinogen like benzene, but there’s little long-term research in humans. That lack of information should nudge users toward caution, not complacency.

Operating filling lines and valves, I saw that workers can get splashed or inhale vapors during spills, transfer, or maintenance. Without gloves, overalls, and proper training, exposure rates climb. Storage tanks sometimes vent or leak, and that means the chemical heads into the local air or soils. If it finds its way down the drain or into a watercourse, aquatic life faces risks. The substance breaks down slowly and can build up in the tissues of fish and small animals.

Reducing risk never boils down to a single gadget or rule. Facilities should use decent ventilation wherever the chemical gets stored, mixed, or poured. Personal protective equipment—gloves, splash goggles, well-chosen coveralls—becomes important, not optional. Training new workers in handling and cleanup lowers the odds of accidents.

Regular walk-throughs with an eye for leaks or accidental spills help spot problems before anyone gets hurt. Companies should make sure spills get cleaned quickly with proper absorbents, never with soap and water that might spread the chemical around. Waste containers labeled for chlorinated organics protect both people and the environment, making sure this substance doesn’t end up in places it shouldn’t.

Where replacement proves possible, less hazardous alternatives deserve a look. My time in chemical plants taught me that some processes hang onto older substances out of habit, rather than real need. Chemists and engineers who keep up with industry journals often find replacement products that do the same job with reduced risk—though switching sometimes takes real investment. No replacement should get used without careful review, but finding better options for worker health can pay off in the long run.

Treat 1-chlorododecane with the same care you’d give a hot tool or a sharp blade. Understand the safety data, and demand protective measures from management if they’re lacking. Complacency opens the door to accidents. A little attention to how this chemical moves, where it gets stored, and how to handle it after an accident can mean the difference between routine work and an emergency.

Respect for these hazards leads to better health, safer workplaces, and fewer stories about regrettable exposures. That’s a lesson everyone in the industry learns sooner or later—best to do it before something goes wrong.

1-Chlorododecane, often found in laboratories and some industrial settings, doesn’t show up in everyday life. It’s a long-chain fatty alkyl chloride, used to make other chemicals, surfactants, and sometimes as a research agent. It owes its sharp smell and clear appearance to its structure. My own experience working in labs taught me that you can’t take shortcuts with chemicals, even ones that seem harmless at first glance. Simple negligence can trigger dangerous spills or worse.

This liquid doesn’t play well with sunshine or heat. Direct sunlight can slowly degrade it, so dark, well-ventilated rooms work best. Temperatures should stay steady and cool—room temperature or below—since higher heat speeds up evaporation, releasing those vapors into your workspace. Vapors are what you want to avoid breathing. I’ve seen many chemists label containers and add vapor-absorbing material like activated charcoal close by, just in case there’s a slow leak.

Containers need to hold up against corrosion, so high-density polyethylene or glass works well. Metal will react, so keep it out of steel cans or anything with rust. Screw-top bottles with tight seals cut down on leaks. Never stack containers more than two layers deep. Over-stacking risks broken bottles if someone accidentally bumps a shelf, turning a routine day into clouded fumes and panic.

Nitrile gloves and lab coats form the front line of defense. Even with “minor” chemicals, I always wore splash goggles—one close call with a routine liquid convinced me years ago. Fume hoods prevent vapors from drifting across workspaces. They also protect other workers, especially since some people feel the effects quicker than others.

Good science means clear labeling on every bottle. Simply reading “dangerous—chlorinated hydrocarbon” stands out far more than a cryptic formula scrawled in faded ink. Separate your storage; 1-Chlorododecane doesn’t belong next to oxidizers or acids. Combine the wrong chemicals, and you risk fire or toxic fumes. Keeping an updated inventory helps, too—no surprises lurking in the back of a cabinet.

Chemical spills come down to how fast and prepared you are. A small leak? Use absorbent pads and ventilate the area. Disposal means bagging the waste in chemical-resistant liners and sending it to a licensed chemical disposal facility. Don’t pour it down the drain. I’ve seen facilities fined for that, plus it’s a risk to groundwater.

Eye wash stations and showers in the room are non-negotiable safety gear. Quick action after exposure limits the damage. Posting emergency contacts and cleaning instructions right by storage areas gives everyone the info they need in a pinch.

Even seasoned staff benefit from regular training. Overconfidence leads to mistakes. Thorough review of safety data sheets and drills with spill kits pay off. Sharing stories of minor incidents reminds everyone to stay alert. If you work with this kind of chemical, being ready beats being sorry—no one wants to scramble because someone didn’t review a procedure.

Treating 1-Chlorododecane with care doesn’t just protect workers or one facility; it protects the wider community from slow leaks or mishaps. Smart, steady discipline keeps both people and environment safer, every single day.

Setting foot in a research lab or production plant, purity is more than a checkbox—it's a dealbreaker. With 1-chlorododecane, the percent purity can set the stage for how efficiently it will integrate into chemical syntheses, detergents, or specialty coatings. My early days hassling with inconsistent batches taught me that a declared “99% pure” isn’t just a guarantee; it's an anchor for any performance expectations further down the process. That single percent between “technical grade” and “analytical grade” can toss hours or weeks of effort into the waste barrel.

Buying from established chemical suppliers like Sigma-Aldrich or TCI often means spotting purity levels ranging from 96% up to 99%, sometimes even higher for specialized applications. But looking closer, the real story sits in the fine print: specifics on water content, residual solvents, or traces of other halogenated substances set the scene for actual usefulness. Once, I ignored a certificate of analysis listing 0.1% hexadecane impurity in a sample, thinking the figure seemed trivial. That oversight translated to frothing side reactions and a batch of polymers fit for nothing. Trust earned from reliable suppliers doesn’t come from marketing gloss, but from the technical sheets shared openly.

Chemists I know, including myself, lean hard on transparency. Infrared spectroscopy, gas chromatography, and NMR show up in most certificates. If a vendor skips these details, alarm bells go off. GC purity above 98% helps ensure nothing unexpected hitchhikes through a reaction. Free chlorine, a hidden danger, can sabotage lab work or make industrial runs unpredictable. My colleagues learned the value of demanding an NMR spectrum years ago, after a shipment labeled “high-purity” left an unyielding residue in our reactors—turns out, it had slipped through with unseen chlorinated byproducts.

1-chlorododecane’s typical commercial grades reveal the priorities of different industries. Developers in fragrance and surfactant sectors lean toward purities near 97% or 98%, with moisture content under 0.1%. Pharmaceuticals put the bar at 99% or better, with solvent residues needing to stay under 0.05%. These numbers spring from both regulatory pressure and hard-learned lessons about product recalls and failed syntheses. I’ve watched teams drop one vendor for another after failing to meet customer demands for batch-to-batch consistency.

Companies aiming for above-average product performance have begun investing in third-party batch testing. Some provide digital access to full certificates of analysis, tracking every analytical curve and impurity. That extra transparency creates confidence in selection, especially for process engineers and research chemists under tight deadlines. My work has benefited from suppliers willing to answer questions about testing procedures and flag batches that run close to the limits.

Quality management doesn't end with the supplier; responsibility stays with users. I make it a habit to double-check each new batch against old standards. It doesn’t pay to skip verification when a slight difference in composition can throw off entire processes. Everyone in the field knows that price often reflects scrutiny in testing and documentation, so saving a few dollars upfront can cost much more in lost time or ruined product.

Experience and recorded results agree—demanding suppliers who stand behind their listed purity helps everyone. Detailed certificates, batch-to-batch reproducibility, and clear limits on moisture and byproducts make better projects, fewer headaches, and a smoother path from purchase order to finished product.

| Names | |

| Preferred IUPAC name | 1-chlorododecane |

| Other names |

Chlorododecane

Dodecyl chloride Lauryl chloride |

| Pronunciation | /ˈklɔːr.oʊ.doʊˈdeɪn/ |

| Identifiers | |

| CAS Number | 112-52-7 |

| 3D model (JSmol) | `load =/cids/8182` |

| Beilstein Reference | 1730785 |

| ChEBI | CHEBI:34287 |

| ChEMBL | CHEMBL141649 |

| ChemSpider | 7136 |

| DrugBank | DB14085 |

| ECHA InfoCard | 03c9c63d-9d96-4bba-b6b5-1a1e76cf0df4 |

| EC Number | 203-931-2 |

| Gmelin Reference | 7948 |

| KEGG | C14092 |

| MeSH | D003694 |

| PubChem CID | 12400 |

| RTECS number | RK2450000 |

| UNII | YDE0M9N0NS |

| UN number | UN3082 |

| Properties | |

| Chemical formula | C12H25Cl |

| Molar mass | 232.84 g/mol |

| Appearance | Colorless liquid |

| Odor | sweet |

| Density | 0.857 g/mL at 25 °C |

| Solubility in water | Insoluble in water |

| log P | 6.90 |

| Vapor pressure | 0.0233 mmHg (25°C) |

| Acidity (pKa) | pKa ≈ -9.3 |

| Basicity (pKb) | pKb: -1.66 |

| Magnetic susceptibility (χ) | -7.83×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.429 |

| Viscosity | 4.18 mPa·s (25 °C) |

| Dipole moment | 1.83 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 395.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -168.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -7670.7 kJ/mol |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. Toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Danger |

| Hazard statements | H315, H319, H411 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P271, P280, P301+P312, P303+P361+P353, P304+P340, P305+P351+P338, P312, P321, P332+P313, P337+P313, P362+P364, P370+P378, P403+P235, P501 |

| Flash point | > 110 °C |

| Autoignition temperature | 260 °C |

| Lethal dose or concentration | LD₅₀ (oral, rat): 3100 mg/kg |

| LD50 (median dose) | LD50 (median dose): 5 g/kg (oral, rat) |

| NIOSH | SAF087 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 1-Chlorododecane: Not established |

| REL (Recommended) | 0.5 ppm |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

1-Bromododecane

1-Iodododecane 1-Dodecanol Dodecane Dodecanal |