The industrial roots of 1,9-Nonanediol Diacrylate stretch back to the 1970s, a time when engineers and chemists felt a growing need for robust materials tailored for emerging demands in polymer science. Many early efforts focused on simple diacrylates, but as technical requirements grew, long-chain solutions caught attention for their flexibility and weather resistance. Nonanediol diacrylate emerged from labs looking to improve the toughness found in existing acrylate monomers. As new patent filings increased through the 1980s, chemical companies strengthened their focus on ways to fill gaps in coatings, adhesives, and resins—driving up investment and pushing production methods out of the laboratory and into pilot facilities.

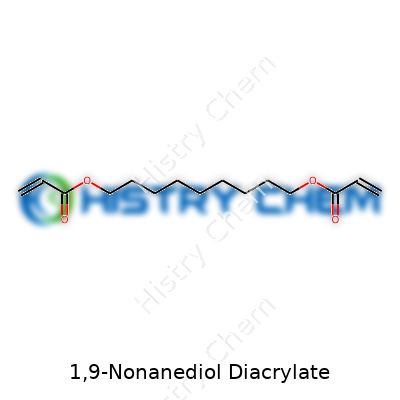

1,9-Nonanediol Diacrylate—known to chemists for its pair of acrylate groups on either end of a nine-carbon backbone—plays a leading role in specialty coatings and polymer applications. Its structure delivers a kind of flexibility lacking in shorter-chained analogs, making it useful in environments needing both strength and bendability. Research papers cite its use not only in high-solid acrylic resins but also as a crosslinker that gives finished products resilience and a longer working life. For anyone in the field of UV-curable products or flexible adhesives, this molecule often bridges the gap between brittle and floppy.

Unlike short-chain relatives, this diacrylate does not come in a brittle form at room temperature. It shows up as a clear, oily liquid, melting below zero degrees Celsius, and boiling at high temperatures—somewhere above 210°C—under reduced pressure. Solubility in many common organic solvents makes it compatible across industrial processes that rely on precise blending. Its double bonds lend themselves well to radical polymerization, and reactivity tests show it cures quickly under ultraviolet light—a property prized for fast-paced manufacturing. With a molecular weight in the higher 200s, this molecule brings heft to formulations, nudging performance upgrades that lighter analogs rarely match.

Producers of 1,9-Nonanediol Diacrylate generally present it with purity north of 95%, putting limits on free acrylic acid and residual diol to avoid unwanted yellowing or odor in finished products. Product labels plainly state hazard codes defined under GHS, pointing out its irritant potential and need for gloves and goggles in daily use. Common packaging options use UV-resistant drums, and any reputable supplier shares a lot-specific certificate of analysis—covering water content, stabilization additives (often MEHQ), and any traces of monomeric impurities. Long experience packaging chemicals has taught the industry to treat diacrylates with respect, especially given their sensitivity to light and need for cool, dry storage.

Chemists make 1,9-Nonanediol Diacrylate through a straightforward esterification reaction. They start with 1,9-nonanediol, reacting it with acrylic acid under controlled temperatures, using catalysts like p-toluenesulfonic acid along with a stabilizer to block runaway polymerization. The process favors removal of water—a trick achieved by azeotropic distillation or molecular sieves. Experience says that keeping air out reduces peroxide risks, so many reactors run under nitrogen. Once distilled and purified, the finished diacrylate arrives as a clear, pale liquid, only requiring minor tweaks depending on the customer’s technical sheet.

Once set up with this diacrylate, the typical workflow involves radical polymerization, especially under UV or electron beam conditions, to lock in toughness and chemical resistance. The two acrylate ends welcome chain extension, and blending with other acrylates enables formulators to fine-tune glass transition temperature, hardness, or even color stability. Researchers sometimes modify it further—by introducing functional groups at the terminal ends—to graft it onto polymers or build networks with more sophisticated mechanical properties. Some studies combine it with thiol-ene chemistry for custom coatings, while others look for greener alternatives to the stabilization process.

On technical datasheets and regulatory filings, this molecule appears under a range of aliases, including Nonanediol Diacrylate, Nona-1,9-diyl diacrylate, or just NDA. Some companies sell it under branded codes, though the structure never changes. The international reach of polymer applications means that regional differences in nomenclature—sometimes using local language suffixes—can pop up, but the basic identifiers remain clearly linked through CAS numbers.

Regulations around 1,9-Nonanediol Diacrylate emphasize workplace ventilation, personal protective equipment, and readiness for spills. Anyone handling this material gets a crash course in dermal and respiratory hazards, since diacrylates have a reputation for causing sensitization after repeated contact. Storage in a dark, cool place reduces the risk of premature curing, and personnel often run periodic peroxide testing to limit buildup of hazardous byproducts. Companies maintaining best practices tie their safety plans tightly to OSHA standards, blending company culture, training sessions, and incident reviews into daily operations. Experience on the plant floor brings out the importance of spill trays and emergency showers, especially during batch changes or loading and unloading of tankers.

Day-to-day use leans heavily on 1,9-Nonanediol Diacrylate’s dual strengths: flexibility and durability. Adhesive manufacturers find it a boon in products for automotive interiors and flexible device screens, while UV-cure coatings depend on its low shrinkage and good impact resistance. Its long carbon chain helps control water uptake, extending the shelf life of electronics sealants and packaging materials. Paint shops prize how it balances hardness and crack resistance, especially in clear coats exposed to sunlight. Teams in 3D printing appreciate its low volatility and fast curing, which helps speed up rapid prototyping and custom object fabrication.

Academic and industrial labs continually push for better ways to process this diacrylate, chasing safer, greener, and more energy-efficient reaction routes. Teams explore biobased feedstocks for both the diol and the acid, hoping to shift production away from fossil resources. Polymer chemists tweak the molecule’s structure for more specialized performance in medical adhesives or flexible electronics. R&D departments run comparative tests alongside other diacrylates, measuring everything from low-temperature flexibility to resistance against hydrolysis and UV degradation. These results reach technical conferences and trade shows, where cross-pollination of ideas often sparks the next round of improvements.

Studies of 1,9-Nonanediol Diacrylate’s effects turn up mostly mild irritancy and moderate sensitization risks, especially after repeated unprotected skin contact. Animal trials report limited acute toxicity, though chronic exposure has prompted calls for expanded long-term data. Occupational medicine looks closely at airborne levels in manufacturing plants, monitoring for any links to respiratory issues. Proper personal protection and real-world chemical hygiene practices keep these risks low. Laboratory work with cell cultures and small mammals helps define safe handling guidelines and exposure limits, supporting regulatory agencies and industry bodies aiming to maintain responsible stewardship.

Looking ahead, demand for performance polymers in solar panels, smart wearables, and flexible electronics looks poised to increase the footprint of 1,9-Nonanediol Diacrylate. Customers driving for lighter, tougher, and more sustainable materials often turn to this monomer during product development. As researchers chase renewable raw material sources, the odds improve for 'green' versions that cut lifecycle emissions and lower environmental impact. Ongoing improvements to photoinitiators, curing equipment, and formulation science promise broader adoption into fields such as optoelectronics, medical adhesives, and advanced composites—making this specialty diacrylate more than just a niche player, but an important tool in tomorrow’s material toolkit.

Walk down the aisles of any hardware store. Pay attention to the shelves of adhesives, glues, and durable coatings. The toughness and flexibility you see in products like dental fillings, UV-curable inks, and high-performance plastics come from special ingredients designed to work under pressure. One chemical that delivers these qualities is 1,9-Nonanediol Diacrylate. This mouthful of a compound acts as a backbone for curing and hardening, connecting molecules together to form sturdy materials.

Most people never see the name of this compound printed on any packaging, but 1,9-Nonanediol Diacrylate helps shape everything from automotive coatings to smartphone screens. Add it to a formula and the final product gains resistance to impact, scratching, and heat. Its structure gives finished polymers flexibility along with hardness, which solves old problems like cracking, warping, or yellowing over time.

Years of hands-on projects have taught me the headaches that come from inferior polymers—think peeling paint, brittle plastics, and adhesives that can’t handle a humid day. Switching to formulas with this ingredient, I noticed better results: smoother finishes, longer durability, and less call-back for repairs. The chemical’s long, nine-carbon backbone absorb stress and movement rather than snapping under pressure.

Manufacturers use 1,9-Nonanediol Diacrylate anywhere they need a blend of strong and flexible. Dental labs mix it into filling materials and sealants, knowing that chewing and temperature swings would wreck ordinary resins. Print shops depend on it for inks that dry fast under UV lamps, then refuse to smudge or flake off packaging and labels. In electronics, the compound helps insulate circuit boards, holding up against heat and constant flexing inside today’s slim gadgets.

No discussion about chemicals should ignore health and safety. Industrial settings treat this material with care, using protective gloves and good ventilation to avoid skin or respiratory contact. Large manufacturers follow strict protocols to minimize worker exposure, guided by up-to-date research on potential hazards. I keep tabs on developments from regulatory agencies and review new studies regularly, and so far, when handled correctly, industry data does not point to serious public health risks.

Environmental impact remains on everyone’s mind. The acrylate family, including this compound, brings questions about persistence in the environment and breakdown products. Current research keeps improving ways to recover, recycle, or safely destroy acrylate-based plastics after their useful life. Community recycling efforts, closed-loop processes, and innovative biobased alternatives offer a path forward. I remain hopeful that sharper research and consumer awareness will guide better practices in both manufacturing and disposal.

1,9-Nonanediol Diacrylate doesn’t show up on labels or in headlines, but modern infrastructure counts on it. Every time a new batch of flexible circuits or hard-wearing coatings rolls off the line, this chemical proves its worth. Building with smarter ingredients supports everything from clean energy technology to next-generation medical devices. The road ahead requires both sharp technical skills and real-world experience, so the materials of tomorrow do more, last longer, and leave a lighter footprint.

1,9-Nonanediol diacrylate often turns up in my research on specialty chemical feeds. It’s a mouthful, but essentially this compound shows up in inks, coatings, and sometimes adhesives. The big question people raise about chemicals like this is pretty basic: are we safe around it, or are there hidden risks?

Let’s get straight to the facts. Handling 1,9-Nonanediol diacrylate requires some respect. The manufacturers flag it as an irritant, and anyone who’s spent time in a chemical lab knows what that means. If this stuff touches skin, expect redness or even a rash. Accidentally get it in your eyes, and you’ll probably reach for the eyewash. Breathing in the vapors, especially in a room without good airflow, can set off coughing or a sore throat. I’ve seen similar acrylate monomers leave people with headaches if ventilation gets overlooked.

Chronic exposure gets even trickier. There’s evidence suggesting that, like other acrylates, sensitization is possible. That means over time, someone can develop an allergy after repeated contact, finding that even small amounts start to set off skin problems. Sensitization like this isn't quick to reverse, making workplace protocols important for those handling it day-in and day-out.

Digging into the data, I find that the main agencies—like the European Chemicals Agency—flag 1,9-Nonanediol diacrylate under skin and eye irritation. There’s less public research about it compared to some of its chemical cousins, but its structure matches other acrylates. That makes me cautious. Tests in animals showed some negative effects at higher doses, but the usual workplace exposure checks help keep levels much lower.

This chemical isn't listed on many cancer warning lists. There's no known risk tied to genetic mutations or reproductive harm, at least at the levels folks in industry would be exposed to. That said, its relatives have caused trouble in the past, and that always keeps me watchful until longer studies offer more solid data.

Waste from production lines or spills rarely makes its way straight into rivers or the soil, but it doesn’t break down quickly. Fish and other life in water can suffer if there’s a big spill. Standard practice involves strict containment, using earth berms, and chemical foams for larger accidents. My time consulting at a polymer plant taught me to stay on guard and never cut corners with waste handling—there’s just too much at risk down the chain.

I’ve watched companies embrace better safety culture by swapping disposable gloves more often and upgrading to splash-resistant goggles. Routine air monitoring and tight labeling stop most accidents before they start. I also recall smaller outfits finding success with job rotation, limiting the total hours any one worker spends near these monomers. Sharing up-to-date material safety data with all staff makes a big difference, too.

The push for greener chemistry is slowly changing what enters our factories in the first place. Companies that prioritize less toxic alternatives without giving up product quality stand out. Work remains, but steady improvements in safety gear and training keep risks manageable, turning what could be a hazardous chemical into just another controlled tool in the toolbox.

Anyone who’s handled chemicals like 1,9-Nonanediol Diacrylate knows caution isn’t just a suggestion—it keeps people out of trouble. What stands out right away is its reactivity. The name might sound technical, but the lessons from dealing with strong acrylates or diacrylates stick: one stray bottle, one hot shed, and suddenly a safe science project turns into an emergency clean-up.

This compound reacts when it gets too warm. My own work in university labs taught me freezer space sometimes runs short, but finding a cool, shaded shelf makes a real difference. Temperatures above 30°C push this stuff toward polymerization—hardening, sometimes with unwanted heat or even a pressurized bottle. If you stash it below room temp, say around 10–20°C, stability holds up for much longer.

Leaving 1,9-Nonanediol Diacrylate exposed to sunlight, even through a window, is asking for trouble. Ultraviolet rays start reactions that even trained chemists can’t easily stop. You want solid, sealed cabinets or containers—think brown glass or metal cans—to keep the light out and the risk down. I’ve seen messy spills stained bright under UV during safety checks; most were avoidable with just a curtain or a better box.

Water in the air and open lids let tiny droplets sneak in, slowly breaking down the diacrylate. Even condensation on a bottle cap will get things moving in the wrong direction. Airtight containers with well-fitting seals always do better. Some labs pump dry nitrogen into their cabinets, but at home, just a tight cap and a casual glance for leaks stops most of the everyday problems.

One mistake too many new researchers make: lining up bottles of diacrylates, organic peroxides, strong acids, and oxidizers right next to each other. Learned from experience, this combination suits neither beginners nor veterans. Just a tiny spill or broken vial can start an unpredictable series of reactions. A couple shelves apart, clear labeling, and a chart listing what shouldn’t touch what make surprisingly strong defenses.

Big bulk bottles seem cheaper, but once you open them, every time you re-cap, the shelf life ticks down. Using smaller bottles and opening them only as needed cuts down on lost product and surprise crystallizations. I’ve seen giant containers clump up or leak long before the label’s expiration. Smaller portions cut those losses.

It’s easy to think “nothing ever goes wrong here”—until it does. Having spill kits, absorbent material, and a printed chemical safety data sheet within reach stops a small mishap turning major. I always made sure anyone around the lab could grab what they needed, not just the person who signed off on the storage plan.

Caring for 1,9-Nonanediol Diacrylate isn’t about making the storage room look tidy. It’s about looking after the people who work nearby and respecting the power inside even plain, clear liquids. Years in the lab taught me that good habits pay off every single day, whether you’re a first-year student or the most seasoned chemist in the building.

1,9-Nonanediol diacrylate turns up most often in products made with ultraviolet (UV) or electron beam (EB) curing. The acrylate groups at each end of this molecule react swiftly under UV light, making it a favorite ingredient for chemists trying to build strong and flexible networks. Picture the clear, hard coatings on your phone screen or the scratch-resistant layers on your sunglasses. Those sometimes owe their durability to acrylates like this one.

Modern assembly shops and packaging lines lean on adhesives that stand up to heat, moisture, and wear. This molecule’s long, flexible carbon chain offers toughness without getting brittle. That comes in handy for manufacturers making waterproof labels, automotive assemblies, or medical tapes that must weather rough handling. A few years ago, at a packaging facility, technicians swapped out older, softer adhesives for new blends containing 1,9-nonanediol diacrylate. Packages came off the line with cleaner bonds, fewer pop-offs in transit, and less sticky residue — reducing complaints and rework.

Anyone who’s handled the gooey resins used by UV-cured 3D printers knows some stay sticky and soft, others turn out too brittle. This acrylate gets added to control shrinkage, make printed parts more flexible, and boost resistance to cracking. Lab techs often tell me they mix it with stiffer acrylates to dial in just the feel and stretch they want. In prototyping shops, the engineer can print a set of dental brackets or a phone case that doesn’t shatter after one drop.

Print shops face constant pressure: fast turnaround, sharp images, and ink that doesn’t run. 1,9-Nonanediol diacrylate steps in to help with curing under UV lamps, bonding pigments into a harder layer. This is the ink you might find on outdoor packaging or signage. In a print trial I watched last year, swapping in this compound cut smudging and made the color pop, drawing compliments from clients needing labels for frozen foods and cleaning products. Less reprinting, happier customers.

Gadgets, electric circuits, and even resilient floors bank on thin coatings to keep moisture and abrasion at bay. Paints or coatings built on this acrylate stick well to surfaces, flex a touch, and harden when zapped with UV light. These features mean fewer chips on a home office chair’s castors, fewer accidents with spilled coffee shorting keyboards, and lower maintenance headaches for facility managers.

Safe handling remains a focus. Like many acrylates, direct skin contact can trigger irritation, so experienced users work behind gloves and ventilated hoods. Companies tracking safer chemistry keep records on these compounds and teach staff proper application. European and North American regulators ask for clear documentation and push for greener alternatives where possible. The demand for reliable, robust materials isn’t going anywhere, and specialty acrylates like this one will keep shaping products we rely on, from gadgets in our hands to cartons on our store shelves.

1,9-Nonanediol Diacrylate doesn’t just roll off the tongue. The name paints a picture for anyone who’s spent time with molecules. Start with nonanediol, a nine-carbon chain with an -OH group at each end—sort of like a rope with sticky tape at both tips. Scientists put acrylate groups on these tips. Acrylate is a vinyl group tacked onto a carboxylic acid, but the acid hydrogen gets swapped for an ester bond. By mixing those together, you get a backbone with both flexibility and two reactive ends—a golden ticket for polymer chemistry.

Think of 1,9-nonanediol diacrylate as a long chain with identical flags at either end. CH2=CHCOO–(CH2)9–OOCCH=CH2 spells it out: the main body is nonane, a 9-carbon stretch, and each "flag" is an acrylate group. Those acrylate ends are eager to react with other chemicals. In the lab, that means this molecule can link up with many others—forming polymers, resins, and crosslinked networks strong enough to anchor the coatings and adhesives we use every day.

There’s nothing abstract about this stuff for people working with coatings or 3D-printed dental parts. Those acrylate "flags" kick off the reaction when hit with UV light or a little heat, meaning that inks set in a flash and floors cure hard enough for forklifts to roll across. Factories rely on this speed. Companies save energy and time, and, since this chemical can be tuned for low toxicity, workers breathe easier.

It’s clear and pourable under normal conditions, which sounds ordinary but makes handling much safer compared to brittle powders or toxic glues. Its chain length gives flexibility—shorter chain relatives can turn rigid and brittle, longer ones get oily or soft. That fourteen-atom span (nine in the main chain, two in each acrylate tail, and the oxygens) balances toughness with ease of reaction.

Everyone in a lab wants chemicals that work as promised, but also don’t hide nasty surprises. 1,9-Nonanediol diacrylate, with its clearly defined structure, helps in assessment. Its diacrylate ends allow high reactivity and encourage full curing, which means fewer stray monomers left behind to irritate lungs or skin. Regulations around acrylates keep tightening; safety data updates all the time. Gloves, goggles, and fume hoods should never feel optional.

In the materials I’ve handled, whether mixing dental resin at a clinic or following up on performance claims at a trade show, thorough curing stands out. Unreacted diacrylate can trigger allergies after repeated contact, so lamps and UV guns matter just as much as the molecule. Responsible companies publish full safety documentation and back it with independent testing, because trust builds with evidence. Crosslinked acrylate networks built from simple structures like this give elasticity, toughness, and chemical resistance the world depends on—from medical devices to wind turbine blades.

Sustainable chemistry has pushed for new acrylate sources from renewable feedstocks. Some current work tries swapping the nine carbons for plant-based backbones or reducing energy demands for curing. Consumers want longer product life and safer indoor air, which means everyone in the industry keeps an eye out for alternatives that can do the same job with fewer side effects. Until then, knowing the chemical logic behind 1,9-nonanediol diacrylate goes a long way in making smart, safe choices—both in the lab and out on the job site.

| Names | |

| Preferred IUPAC name | di(prop-2-enoyloxy)nonane |

| Other names |

1,9-Nonanediol diacrylate

Diacrylate ester of 1,9-nonanediol Nonanediol-1,9-diacrylate Nonamethylene glycol diacrylate 1,9-Diacryloyloxynonane |

| Pronunciation | /ˈnəʊ.nən.daɪ.ˈɒl daɪ.ˈæk.rɪ.leɪt/ |

| Identifiers | |

| CAS Number | 41132-60-7 |

| Beilstein Reference | 1363087 |

| ChEBI | CHEBI:87054 |

| ChEMBL | CHEMBL512619 |

| ChemSpider | 17615342 |

| DrugBank | DB14625 |

| ECHA InfoCard | 03d9abc8-8333-4a73-9c57-f1a3e888c063 |

| EC Number | 609-061-9 |

| Gmelin Reference | Gmelin 108157 |

| KEGG | C19147 |

| MeSH | D017709 |

| PubChem CID | 86638228 |

| RTECS number | RR1750000 |

| UNII | Q5W4EC6EZI |

| UN number | UN3082 |

| Properties | |

| Chemical formula | C15H22O4 |

| Molar mass | 312.41 g/mol |

| Appearance | Colorless to light yellow liquid |

| Odor | Faint acrylic odor |

| Density | 1.006 g/cm³ |

| Solubility in water | Insoluble |

| log P | 0.9 |

| Vapor pressure | <0.00001 mmHg (@ 25 °C) |

| Acidity (pKa) | 12.9 |

| Magnetic susceptibility (χ) | -65.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.458 |

| Viscosity | 29 mPa·s (25°C) |

| Dipole moment | 3.07 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 721.9 J/mol·K |

| Std enthalpy of formation (ΔfH⦵298) | -726.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4970.2 kJ/mol |

| Hazards | |

| Main hazards | Causes skin irritation. Causes serious eye irritation. May cause an allergic skin reaction. Toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H302, H315, H317, H319, H411 |

| Precautionary statements | P280-P305+P351+P338-P337+P313 |

| NFPA 704 (fire diamond) | 1-2-2-✱ |

| Flash point | > 137°C |

| Autoignition temperature | 215 °C |

| Lethal dose or concentration | LD₅₀ (oral, rat) > 5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): >2000 mg/kg (Rat, oral) |

| NIOSH | NA0870000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.05 ppm |

| Related compounds | |

| Related compounds |

1,6-Hexanediol diacrylate

1,4-Butanediol diacrylate 1,10-Decanediol diacrylate Neopentyl glycol diacrylate Polyethylene glycol diacrylate Trimethylolpropane triacrylate |