Decades ago, the chemical industry searched for new ways to toughen plastics and coatings without bumping into brittleness. Some smart chemists came up with 1,6-Hexanediol Diglycidyl Ether—an outgrowth of glycidyl ether technology that stretches back to the rapid push for better polymer resins in the late 20th century. As the need for flexible, resilient, chemical-resistant materials grew, this compound joined hardeners and crosslinkers in labs and factories focused on epoxies. Over time, it moved from being a pure research chemical to a staple ingredient in large-scale manufacturing thanks to its unique bridge structure and balanced reactivity.

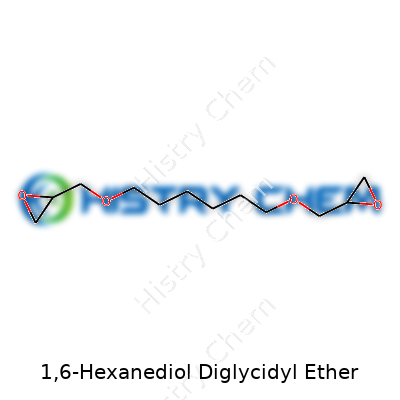

1,6-Hexanediol Diglycidyl Ether bears a molecular structure built around a six-carbon chain, flanked by reactive oxirane rings. This structure lends a rare blend of flexibility and chemical strength. Working in coatings, adhesives, electronics, and even composites production, the compound doesn’t just bridge polymers but improves the balance between hardness and elongation. Everyday items like floor coatings, electronics encapsulants, and some specialty plastics owe their performance to these chemical bridges.

Folks handling this chemical notice a colorless to pale yellow liquid, sweet odor sometimes surfacing in poorly ventilated labs. With a boiling point above 120°C and viscosity staying moderate at room temperature, users find it easy to mix into epoxy resin bases. Its low volatility means less inhalation risk, which fits demanding workplace safety standards. Chemically, its two epoxide groups make it a strong crosslinker, reacting readily with amines and acids. Water solubility sits low, so producers rely on organic solvents for blends and cleanups.

Manufacturers label drums and tins of 1,6-Hexanediol Diglycidyl Ether by purity, often at 98% or above, and they provide CAS numbers—though too many overlook batch traceability in their hurry. Shipping containers list UN numbers and GHS warnings due to the sensitizing risks the compound poses. Material safety data sheets drill into reactivity with acids, bases, and strong oxidizers, pushing companies to store the barrels in shaded, well-aired storage away from food and water supplies. The stuff usually arrives in 200-liter drums, clear plastic or aluminum-lined, for moisture and light protection.

Makers synthesize this chemical through a reaction of 1,6-hexanediol with epichlorohydrin, catalyzed in an alkaline environment. Reacting 1,6-hexanediol with excess epichlorohydrin sparks the formation of diglycidyl ethers; sodium hydroxide or another strong base then helps close the oxirane rings. Engineers pay close attention to temperature control and byproduct removal—tiny variations mean the difference between a pure product and resin clogged with side products. Filtration and vacuum distillation finish the job, stripping out water and unreacted monomers to deliver a clear, stable liquid ready for the market.

The double epoxide groups on this molecule crave reaction partners. In cured epoxies, they bond with amines, thiols, or carboxylic acids, so users can tune mechanical and electrical properties by choosing their hardeners carefully. Modifications abound: some research teams have grafted fluorinated or silane groups onto the parent molecule, hoping for lower flammability or better wetting properties in tricky applications like aerospace or electronics. The base ether link resists hydrolysis, but harsh acids do break it down—one reason why specialty environments, like acid tanks, demand extra attention in both design and maintenance.

Over the years, this compound picked up pack names across suppliers and contexts. Some call it 1,6-Diglycidoxyhexane or use trade names favored by multinational chemical houses: PEGDE-6, HDGE, Dihexanediol Glycidyl Ether, or even just “Flex-Epoxy-6” in industrial shorthand. Broader trade sees it tucked into product blends as a flexibilizer or crosslinker. Recognizing the synonyms matters, since regulatory documents and safety manuals hardly ever settle for a single label—experienced buyers always double-check to avoid mix-ups or supply chain confusion.

Long-term use of this chemical highlights the push and pull between performance and safety. Being a diglycidyl ether, it can sensitize skin and lungs on repeated exposure. I remember folks in the plant who started out forgetting gloves or goggles—their hands flared up with redness after a few weeks, teaching a lesson you never want to repeat. Workplaces using this compound have to enforce strong ventilation, gloves, eye shields, and regular air monitoring. Beyond personal safety, spill management demands sorbent pads and immediate disposal to avoid environmental discharge. Global regulations under REACH and OSHA keep getting tighter for glycidyl compounds, pressing industry to find substitutes or engineer better handling safeguards.

Walking around a big coatings or adhesives facility, you see 1,6-Hexanediol Diglycidyl Ether feeding into tank mixers, helping give epoxies their ability to flex without falling apart. Laminates for wind turbine blades, high-build floor coatings in warehouses, and specialty encapsulation for sensitive electronics all benefit from this chemistry. Compared with old-style brittle epoxies, resins treated with this compound shrug off microcracks and keep their shape under heat or stress. Automotive repair kits, marine maintenance supplies, and even some corrosion-control paints lean on the stuff to survive year after year.

Laboratories still treat this molecule as a base for innovation. R&D teams hunt for safer or greener production routes, aiming to consume less energy during the critical ring-closing steps. Some labs are tweaking the main chain length—testing octanediol or dodecanediol analogs to compare flexibility and cure rates. High-performance sectors want epoxy blends with milder emissions, and chemists use 1,6-Hexanediol Diglycidyl Ether as a building block for new prepolymers and oligomers. Published research keeps an eye not just on polymer strength, but also on sustainability, toxicity, and recyclability, as consumer pressure grows for safer, longer-lasting materials.

Toxicologists have dug into the effects of this compound, especially since epoxides can cause allergic reactions or irritation. Studies run by big universities and industrial safety groups show that repeated skin contact over months leads to sensitization in a slice of the population—even those wearing gloves sometimes run into problems if cleanup routines slip. Acute oral toxicity runs lower than many solvents, but chronic inhalation or ingestion spells trouble for kidneys and liver, prompting companies to beef up exposure controls and medical monitoring. The chemical rarely makes it into water tables or air, but in spill events, emergency teams act fast to limit animal and plant exposure.

Compatibility and flexibility drove early demand. Looking forward, the biggest opportunities link to green chemistry and circular production models. Makers dip their toes into bio-based alternatives for the hexanediol core, aiming to cut fossil fuel dependence and stand out in eco-label markets. There’s action in waterborne systems that cut solvent emissions—using 1,6-Hexanediol Diglycidyl Ether as a low-viscosity resin that still toughens up under UV or thermal cure. As electronics miniaturize and mobility options explode, the demand for durable, flexible, high-purity epoxies will not fade. Companies stuck on old routes risk falling behind as global bans tighten and customers grow savvier about what goes into their products. Training workers, upgrading ventilation, and finding less hazardous cousins to diglycidyl ethers—these moves promise not just compliance, but steady, responsible growth in chemical manufacturing, research, and safe application across countless vital industries.

Roll up your sleeves and step into a workshop where glue isn’t just glue—it’s chemistry in action. 1,6-Hexanediol diglycidyl ether shows up on containers labeled with lots of important safety instructions. Its main task? Making epoxies and resins work better. Imagine building a kitchen countertop, and you want staying power and some flexibility. This ingredient brings just that. It acts as a reactive diluent, which means those thick, sticky epoxies become easier to pour, brush, or mold. Thinner material flows into every crack, making repairs cleaner and builds solid without chipping like old pottery.

My first exposure to industrial adhesives happened in a woodworking shop, where scratches and dropped tools seemed to be part of every day. Folks there cared about the finish and strength, and those big drums with chemical names made all the difference. 1,6-Hexanediol diglycidyl ether lets epoxies flex just enough to handle heavy use without falling apart. So, if the weather swings or something heavy lands on that floor or bench, the bond holds strong. Curing gets a little more even, so you don’t get random weak spots. That makes projects last longer and withstand regular abuse.

Take a stroll through factories or shipyards: every painted metal surface you pass faces water, changes in temperature, and chemical spills. Paints and coatings mixed with 1,6-Hexanediol diglycidyl ether stand up to those challenges. That’s part of the reason marine coatings use this additive. The stuff keeps saltwater and chemicals from breaking through and eating away at surfaces. It does not cover only boats—pipelines, machines, and tanks that transport or store harsh stuff all count on this chemical’s strengthening power.

Safety and performance come first—there’s no trade-off. Manufacturers rely on data from tests that assess how well epoxies resist abrasion and chemical stress. Academic journals like the Journal of Applied Polymer Science provide studies showing improvements in both mechanical strength and chemical resistance with this specific ingredient. Industry regulators also set strict standards, tracking levels of volatile organic compounds and making certain that workers using these products know how much protection they need. Safety Data Sheets go deep into skin or eye risk, so gear up before you pour or mix.

Working from a sustainability angle, the science community hasn’t turned its back on 1,6-Hexanediol diglycidyl ether, but some are testing ways to lower risk. Safer handling practices—like improved ventilation and mixing stations—already help a lot. People are keeping their eyes on greener formulations, such as bio-based reactive diluents. The push comes from new environmental policies along with buyer demand for safer products. Still, ask anyone patching a concrete floor or sealing an industrial tank: they need materials that never buckle under pressure.

If you’re in the trenches, you want tools that fit the job. 1,6-Hexanediol diglycidyl ether brings workhorse reliability to industries that won’t accept shortcuts. Users balance cost, safety, and durability every project. Good training, strong rules, and better technology can dial down risk so we stay healthy while getting strong, flexible results. The end goal: keep buildings, boats, and machines running longer with less trouble. That’s real value, proven by both the numbers and common sense from the shop floor to the biggest shipyard.

Many folks in the coatings, adhesive, and plastics industry come across 1,6-Hexanediol diglycidyl ether, a chemical often used to toughen up epoxy resins. You might find it in paints that cover factory floors or those strong industrial glues that keep furniture together. Some also find it handy in the electronics world because it helps give circuit boards that durable, protective shell.

The big question a lot of people have: does being around this chemical put health at risk? No one wants to show up at work and wonder if what’s in the air will leave them with a sore throat—or worse, chronic breathing trouble down the line. A few years ago, while touring a mid-sized sheet molding plant, the smell coming from the resin room made my nose burn and eyes itch, which wasn’t reassuring. Supervisors handed out gloves and masks, but few took them seriously.

The Material Safety Data Sheets (MSDS) on 1,6-Hexanediol diglycidyl ether don't mince words: it can irritate eyes, skin, and lungs. Shortness of breath, headaches, or rashes aren’t rare if vapors hang heavy in a room. The European Chemicals Agency tags it with hazard statements noting risk of skin burns, allergic reactions, and eye damage. The US National Institute for Occupational Safety and Health (NIOSH) points to similar issues.

Some research suggests this compound can even cause respiratory sensitization. Once someone gets sensitized, even tiny amounts may trigger asthma-like reactions. Dermatitis isn’t uncommon either. It isn’t just about getting it on your skin—a common concern is inhalation. Vapors may not be visible, but spending hours around them can catch up to anyone who skips the ventilation or leaves personal protective equipment on the shelf.

The laws around this chemical aren’t as tough as they are for formaldehyde or lead, but plenty of countries set exposure limits. The Occupational Safety and Health Administration (OSHA) and European regulators require companies to keep workplace concentrations below certain thresholds and to provide ways for workers to avoid contact. My own experience lines up: plants that took employee training and spill control seriously saw fewer health complaints and staff stuck around longer.

Switching to safer alternatives isn’t always possible, so the next best thing boils down to tight controls and protection. Good ventilation cuts vapors fast, making masks and gloves less of a “last line of defense” and more of a backstop. Frequent air quality testing in production rooms, plus clear, consistent staff training, go a long way. Facilities I've visited that rotated roles and kept track of who spent time in the highest-risk zones saw fewer repeat issues and improved morale—folks didn’t feel like canaries in a coal mine.

Pressure grows on companies to find greener, safer chemicals. For now, though, taking exposure seriously keeps workers safer. Open windows, working extractor fans, and protective gear might not seem flashy, but sometimes the basics beat fancy promises. I’ve learned small investments in safety gear and better practices make the biggest impact on everyone’s day-to-day health.

Years of working with epoxy hardeners and reactive glycidyl ethers have taught me—nothing drags down a project faster than poor storage. 1,6-Hexanediol Diglycidyl Ether falls squarely into that group of specialty chemicals where mishandling invites bigger problems, whether you’re mixing up an advanced polymer or running a busy warehouse.

The molecule itself holds two reactive epoxide groups, so it's little surprise that this liquid looks for opportunities to react, even outside the lab or plant. Letting moisture or heat sneak into storage spaces doesn’t just hurt product quality; it risks health and safety, as well. Maybe that sounds overdramatic, but I've seen what happens when safety gear is left aside for “just a minute” — off-odors, skin irritation, ruined material. Once opened to moisture or high temperatures, jars of glycidyl ethers can thicken or degrade, losing their edge and, in turn, their intended use.

Over the years, facility managers realize that storage guidelines from the safety datasheet aren't theoretical. Keep 1,6-Hexanediol Diglycidyl Ether cool—usually below 30°C (86°F). Rooms without direct sunlight or heat sources prevent formation of peroxides and decomposition. Temperature swings accelerate reactions, so a consistent environment pays off. One distribution manager I worked with set aside one corner in the warehouse, capped it with a separate thermostat, and checked the reading every workday morning. That simple discipline saved more money than any other single process change.

Air matters just as much. Sealing containers tightly after every use keeps humid air out. Once air finds its way inside, epoxides start to lose their punch. I’ve made the mistake of thinking, “That pail looks closed enough.” Fast forward a week—filters in the ventilation system clog, the chemical darkens, performance slips. Double-checking lids and regularly swapping out damaged seals prevent wasted stock and fewer headaches for the team.

A locked chemical storage cabinet, made from steel with an epoxy lining, stands up to accidental splashing or small leaks. Any company—large or small—benefits from clear labeling, eye wash stations within arm’s reach, and a spill kit up to the task. I’ve also learned to keep incompatible materials miles apart. Storing strong acids, bases, or oxidizers next to glycidyl ethers invites fire hazards, some of which don’t give second chances.

Even a whiff of this stuff makes it clear—no one should take short cuts on personal protection. Nitrile gloves, safety goggles, and lab coats beat rashes or headaches every time. I insist on proper ventilation in storage rooms, not just for crew comfort but to limit any slow buildup of vapors, which could trigger headaches or worse. Safety data points out that 1,6-Hexanediol Diglycidyl Ether is toxic to aquatic life. Responsible outfits store and transport it up off pallets, ready to corral leaks before they hit a floor drain.

Regular checks matter more than any fancy equipment. I check container walls for sweating or bulges, since those signal runaway reactions. Any hint of yellowing or cloudiness—out it goes, no debate. Standard operating procedures may sound dull, but they keep teams confident, buyers happy, and regulators off your back. Documentation builds trust, inside and out. Over time, the difference between a smooth-running shop and a problem factory usually tracks back to basic habits around chemical storage.

Anyone who works with epoxy systems or advanced coatings finds themselves crossing paths with 1,6-Hexanediol Diglycidyl Ether eventually. It’s valued for its ability to improve flexibility and chemical resistance in finished products. There’s no denying its usefulness, but this is not a substance to take lightly. If you’ve spent enough time on factory floors or labs, you’ve seen what happens when someone gets complacent about chemical handling. Shortcuts on safety can lead to problems that stretch far beyond a sore throat or itchy skin.

Skin contact with this chemical brings on irritation in many cases. Extended exposure without proper protection can bring about rashes or worse, thanks to its corrosive character. Inhalation presents another range of problems — from sore nasal passages to more serious respiratory issues. During one summer internship, I watched a colleague suffer from headaches and persistent skin irritation, all traced back to a poorly sealed bottle and a skipped set of gloves. Proper training and protective gear weren't treated as optional after that incident.

Good airflow makes a difference, but fans and open windows serve as a first line of defense, not the finish line. Fume hoods, local exhausts, or effective general ventilation systems should always be working in laboratories or shops handling this chemical. These setups pull vapors away before they settle into lungs. Relying only on natural airflow invites trouble, especially in cramped or busy production spaces.

Nitrile or butyl rubber gloves stand up well to 1,6-Hexanediol Diglycidyl Ether. Standard latex gloves dissolve or tear too easily. Lab coats mean less risk to regular clothing and skin, and safety goggles with side shields stop splashes from reaching the eyes. Don’t forget proper respiratory protection when vapors or aerosols form. Disposable masks won’t cut it—use a half-face respirator with organic vapor cartridges. This practice keeps lungs in good shape, which everyone in the industry values over shortcuts.

Keeping this chemical in sealed, labeled containers, tucked away from heat and direct sunlight, slows down degradation and vapor release. Flammable storage cabinets offer extra security. I once walked into a workshop after a minor spill; clear signage and a simple checklist next to the response kit kept panic away and minimized the fallout. Absorbent pads, neutralizers, and clear processes work better than a mad scramble for paper towels or a hose.

No label or manual replaces hands-on experience with proper training. Creating a culture where even the most seasoned employees double-check procedures keeps everyone safe. Refreshers happen regularly where I work, so nobody forgets protocol or the reasons behind it. Safety walks and quick quizzes remind staff how easily mistakes can become medical emergencies.

Handling 1,6-Hexanediol Diglycidyl Ether safely is about respect—for both the chemical and the people near it. Proper procedures, tested gear, and the willingness to speak up about risks make the difference between smooth operations and avoidable harm. This might not grab headlines, but behind every clean bill of health is the quiet, ongoing dedication to doing things right the first time.

Anyone who’s ever worked with industrial polymers or epoxy coatings probably recognizes the name 1,6-Hexanediol Diglycidyl Ether. This molecule steps in to toughen resins or boost performance in everything from electronics to structural adhesives. Its chemistry explains why it gets chosen so often. A quick look at its structure: at the core sits a six-carbon hexanediol chain, decorated at each end with glycidyl ether groups. Both sides offer reactive epoxy rings, primed to connect with other molecules during reactions—think of them as docking points in big molecular assemblies.

The official formula looks like this: C12H22O4. Picture a flexible carbon chain, six links long, with hydroxyl groups swapped out for the much more reactive glycidyl ether extensions. What really stands out here are the epoxy groups (oxirane rings). Each creates an opportunity for the molecule to join with amines, acids, or other curing agents during polymerization. This lets users build tough, interconnected plastics or adhesives without much fuss.

I’ve worked on formulating epoxy resins, and I’ve noticed small tweaks in structure, like those in 1,6-Hexanediol Diglycidyl Ether, make a big difference. The long, flexible backbone actually softens and stretches the cured product instead of turning brittle. The glycidyl groups remain highly reactive, but the presence of a mid-length chain in between lets finished materials resist cracks better under impact or vibration.

This isn't just chemistry trivia. The physical work that these molecular structures do—they make stronger, more resilient composites or coatings, used in wind turbine blades, automotive body panels, or even the simple structural adhesives holding consumer products together. Epoxy groups latch onto other molecules tightly. In the process, they form networks with properties dialed in through the size of that backbone. So, a longer chain in the base structure, like in 1,6-Hexanediol Diglycidyl Ether, gives more flexibility, while all those reactive ends deliver strong adhesive bonds.

Environmental and health considerations always enter the picture. Workers exposed to these chemicals need solid training and proper protective gear. Epoxy compounds can cause skin sensitization or respiratory issues if misused. Safety data sheets stress handling with gloves and good ventilation. Some research focuses on finding safer alternatives, but as it stands, careful use lets industry benefit from the fine-tuned properties offered by this kind of molecule.

Demand for greener chemistry is rising. My experience tells me that industry seeks solutions both in how epoxies like these get synthesized and how they break down after their service life. Bio-based feedstocks for the starting hexanediol could cut fossil fuel use. Improved formulations aim to lower required curing temperatures, which saves energy and shrinks the carbon footprint of product manufacturing. Another idea gaining attention is recycling composite materials built from these epoxies, even though their tough cross-linked structure makes mechanical recycling tricky. New chemical recycling techniques are showing some promise, with researchers working to 'unzip' these complex structures.

All this sits on a foundation of chemistry—a molecule thoughtfully designed, balancing reactivity with flexibility. It shapes the practical products we use, and also steers the conversation about safer, more sustainable materials. Crafting these kinds of engineered molecules opens up both opportunities and hurdles, but pulling apart their structure gives real insight into how and why our materials perform the way they do.

| Names | |

| Preferred IUPAC name | 2-[[6-(oxiran-2-ylmethoxy)hexyl]oxymethyl]oxirane |

| Other names |

1,6-Bis(glycidyloxy)hexane

Hexane-1,6-diol diglycidyl ether 1,6-Diglycidyloxyhexane 1,6-Diglycidyl ether of hexanediol HDGE 1,6-Hexanediol-bisglycidyl ether |

| Pronunciation | /ˌhɛk.səˈniː.di.ɒl daɪˈɡlɪk.ɪdɪl ˈiːθər/ |

| Identifiers | |

| CAS Number | 16096-31-4 |

| Beilstein Reference | 1740530 |

| ChEBI | CHEBI:82717 |

| ChEMBL | CHEMBL2106748 |

| ChemSpider | 14172 |

| DrugBank | DB11274 |

| ECHA InfoCard | 29c90813-ef9f-4be5-9f97-6daf56e4d1b4 |

| EC Number | '603-983-2' |

| Gmelin Reference | 85916 |

| KEGG | C19614 |

| MeSH | D000077222 |

| PubChem CID | 24893408 |

| RTECS number | MP4825000 |

| UNII | QE2361MI5N |

| UN number | UN2735 |

| CompTox Dashboard (EPA) | 'C497871' |

| Properties | |

| Chemical formula | C12H22O4 |

| Molar mass | 258.33 g/mol |

| Appearance | Colorless to light yellow transparent liquid |

| Odor | Faint characteristic |

| Density | 1.06 g/cm³ |

| Solubility in water | miscible |

| log P | 0.5 |

| Vapor pressure | <0.01 mmHg (20°C) |

| Acidity (pKa) | 14.47 |

| Basicity (pKb) | 13.21 |

| Magnetic susceptibility (χ) | χ = -9.80e-6 cm³/mol |

| Refractive index (nD) | 1.4500 |

| Viscosity | 12-22 mPa.s (25°C) |

| Dipole moment | 2.12 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 476.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -4706 kJ/mol |

| Pharmacology | |

| ATC code | D01AE22 |

| Hazards | |

| Main hazards | Causes skin irritation. Causes serious eye irritation. May cause an allergic skin reaction. Toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H317, H319, H411 |

| Precautionary statements | P261, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-1-1 |

| Flash point | 108 °C |

| Autoignition temperature | 230°C |

| Explosive limits | Explosive limits: 1.3–23% (V) |

| Lethal dose or concentration | LD50 (oral, rat): 2,500 mg/kg |

| LD50 (median dose) | LD50 (oral, rat) 2,330 mg/kg |

| NIOSH | SE3775000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 3 ppm |

| Related compounds | |

| Related compounds |

1,4-Butanediol diglycidyl ether

Neopentyl glycol diglycidyl ether 1,2-Cyclohexanedimethanol diglycidyl ether Poly(ethylene glycol) diglycidyl ether Bisphenol A diglycidyl ether |