Years before advanced organic synthesis entered mainstream laboratories, chemists were already searching for building blocks to link, extend, and functionalize carbon chains. 1,6-Dibromohexane became a reliable backbone for these efforts, first as an offshoot of simpler dihalide syntheses and eventually as a specialty chemical in its own right. Early research on haloalkanes in the early 20th century focused on short chains and their reactivity. Once laboratory glassware and purification caught up, the six-carbon dibromo variant started to see use in industrial and pharmaceutical settings as a linker for more complex molecules. This was a crucial moment: organic chemists could suddenly construct large, flexible chains for developing drugs, polymers, and advanced materials. I remember an old organic chemistry professor praising dibromohexane’s role in enabling modern phase transfer catalysis and building complicated compounds—its dependable reactivity and simple chain shape offered predictability in an era where synthetic chemistry faced so much guesswork.

1,6-Dibromohexane looks unassuming—a clear, oily liquid at room temperature, with a faint, halogen-like smell. Its molecular formula, C6H12Br2, gives it a certain heft in the bottle, and the two terminal bromine atoms are positioned precisely to invite nucleophilic attack, making it powerful as a chemical intermediate. Chemists look for these traits when designing new drug candidates, cross-linkable polymers, or advanced materials. Suppliers typically offer several levels of purity. The highest grades, purified by careful distillation, come packed in amber bottles to guard against light degradation—a subtle but crucial packaging detail that speaks to hard-learned experience in chemical handling. For researchers and manufacturers, a well-sealed bottle of 1,6-dibromohexane quickly becomes the lynchpin in multi-step synthetic plans.

1,6-Dibromohexane stands out as a dense, colorless to pale yellow liquid with a boiling point close to 260°C and a melting point around -4°C. The density, sitting at 1.5 g/cm³, immediately reminds one of its bromine content. It does not mix with water, blending much better with organic solvents like ether, chloroform, or acetone—a property that guides its separation, purification, and subsequent reactions. As with most long-chain alkyl dihalides, it shows chemical stability under normal conditions but reacts briskly with nucleophiles, making it particularly valuable in SN2-type substitutions. Its vapor may carry irritation risks, and direct skin contact feels slick but comes with cautionary tales about persistent dermatitis—words every new chemist hears in safety talks.

Chemicals like 1,6-dibromohexane rely on accurate labeling and tight quality control. Standard product labels list CAS number 629-03-8, molecular weight of 259.97 g/mol, and assay values, often above 98% for most research applications. Suppliers also note hazardous nature with the GHS pictograms for acute toxicity and environmental harm. Storage and transport information states that it should stay tightly closed in cool, ventilated spaces, far from strong bases and oxidants. Familiar safety jargon comes alongside, but operationally, what researchers rely on most is the assurance that product purity and labeling allow straightforward integration into synthesis schemes. I have experienced, in academic labs and process facilities, the immense frustration that comes from mislabeled or subpar intermediates, underscoring how technical specs are far from mere bureaucracy—directly impacting yield, purity, and safety.

Industrially, production of 1,6-dibromohexane uses a straightforward two-step approach. You start from the readily available 1,6-hexanediol or 1,6-dichlorohexane, then substitute halogens or hydroxyls for bromine using reagents like phosphorus tribromide or hydrobromic acid. It’s a reliable route: treat hexanediol with PBr3 under dry conditions and distill to isolate the dibromo product. Yields can reach 80% with careful drying and purification. On a lab scale, I’ve run this reaction in round-bottom flasks cooled in salted ice baths to keep the exotherms under control—one slip and you can lose significant product to decomposition or even glassware failure from pressure buildup. Industrial operations scale this up with jacketed reactors and in-line purification—for those of us with memories of cracked glass and wasted time, automation and hazard mitigation represent seismic progress.

1,6-Dibromohexane acts as a versatile linker in synthetic chemistry. Nucleophiles, such as amines or alkoxides, attack the terminal bromines, creating bis-functionalized compounds. You can quickly build amines, ethers, sulfides, or even complex macrocycles with a six-carbon tether at the core. A favorite reaction in the classroom and the industry involves coupling with primary amines to make hexamethylene-based diamines—materials that anchor segments in polymers, surfactants, or specialty ligands. Over the years, I’ve watched this molecule serve as both a tool for simply extending chains and as a gateway for inventing entirely new classes of cyclized compounds—its flexibility is concrete, not theoretical.

Chemists rarely use only one name for a compound, and 1,6-dibromohexane is no exception: 1,6-Bromhexan, hexamethylene dibromide, dibromhexane, and α,ω-dibromo-n-hexane have all appeared across catalogs, safety data sheets, and research papers. Some European suppliers favor Hexan-1,6-dibromid. For international researchers, knowing every variant matters once you start ordering chemicals from vendors that may default to IUPAC, common, or even trade names. Years of struggling with database searches have taught me never to rely on a single synonym when tracking down literature on dibromohexanes—you dig deeper when you have all the right names.

1,6-Dibromohexane deserves respect in the lab and factory both. It brings moderate toxicity, particularly as a skin and eye irritant, and inhalation overexposure leads to dizziness or nausea. Industrial hygiene guidelines do not recommend relaxation: wear gloves made of nitrile or neoprene, use chemical splash goggles, and operate only under fume hoods. For spills, granular absorbents help manage small accidents, but workers need chemical-lab training—improvisation in the event of exposure only leads to increased risk. Safety data stress the importance of waste control, as this compound’s halogenated nature means it must not enter general effluent. In my experience, rigid adherence to containment and decontamination protocols, supported by clear procedures, reduces both health risks and regulatory headaches.

Applications for 1,6-dibromohexane stretch across pharmaceuticals, polymer synthesis, analytical chemistry, and specialty materials. In the pharma world, it helps create long-chain diamines for drug conjugation or as a spacer in peptide modification. Polymers often start their journey here: synthesized dibromohexane links with diamines to make nylon-6,6 analogs, specialty polyurethanes, or custom elastomers with exact chain lengths. Chemical manufacturers rely on its reactivity for custom surfactant production. I once worked in a facility that designed macrocyclic compounds for environmental sensing—the controlled rigidity of the hexane core gave us products with binding sites precisely where we wanted. Sometimes the industry’s reliance on a compound like this doesn’t hit you until you hear how many different research groups cite it in unrelated fields, from electronics to biomedical coating development.

Every year, new uses and modifications for 1,6-dibromohexane keep showing up in journals. A significant share of R&D explores making functional molecules more efficiently, reducing hazardous byproducts, or navigating chiral synthesis to build helices and rings for advanced applications. Researchers have investigated green chemistry approaches, aiming to replace toxic solvents or reagents and to recycle bromine where possible. Multinational collaborations dive into its applications as a building block for cross-linked networks in smart materials, hydrogels, and drug delivery vehicles. Over time, synthetic challenges shift: new catalysts now offer more precise control, and process chemists look for higher selectivity and lower energy use in manufacturing. I've noticed a trend—every few years, a new, more sustainable scheme emerges, echoing the industry's growing responsibility to reconcile performance with safety and environmental stewardship.

Toxicologists studying 1,6-dibromohexane focus on its acute and chronic health impact. The primary concern has always been skin and respiratory irritation, but research has flagged potential liver and neural effects at high exposure levels. Animal studies suggest moderate systemic toxicity with prolonged contact, driving regulations to cap allowable workplace exposure. Data remain less robust for environmental fate; persistence and bioaccumulation remain open questions. I feel strongly about strengthening oversight here, both for worker safety and for surrounding communities—years in research and industry showed me too many cases where ignorance led to unnecessary health scares. Developing real-time detection systems and closed-loop handling might solve many of these problems before they start.

Looking ahead, 1,6-dibromohexane will still hold substantial importance. Green chemistry’s rise pushes manufacturers toward less toxic reagents and waste-free processes. The hope is that continuous-flow synthesis and innovative catalysts drive energy use down and reduce harmful emissions. Materials scientists and bioengineers remain hungry for reliable, high-yield linkers for assembling new functional systems, from responsive polymers to bioactive scaffolds. Digital chemistry and AI-guided synthesis may soon optimize conditions and reduce trial-and-error in process design. Still, much depends on transparent reporting of toxicological data, open platforms for sharing best practices, and honest commitment from all stakeholders to improve handling—from lab benches to bulk production lines. My time among chemists, policy-makers, and engineers leaves no doubt: responsible innovation, grounded in practical experience, shapes a future where chemicals like this both enable progress and protect people.

People don’t often talk about chemicals like 1,6-Dibromohexane outside of specialized labs, but its influence reaches wider than most think. This compound shows up a lot in the world of chemical synthesis. It works as a building block—literally a link in the chain when chemists put together bigger, more complex molecules. You find it at the bottom of many specialized supply shelves because its six-carbon chain with bromines at each end is perfect for certain custom reactions.

Polymer chemists like 1,6-Dibromohexane because it helps create long-chain molecules. The presence of two bromine atoms, one on each end, lets it attach cleanly to other chemical groups. This feature makes it a favorite for making specialty plastics or rubbery materials that call for particular stretches and strengths. Research articles often describe experiments where this compound became a bridge or cross-link between different polymers, improving how tough or stretchy the final material turned out.

Organic chemists use 1,6-Dibromohexane to build and modify molecules for everything from pharmaceuticals to smart materials. Bromine makes a great “leaving group,” so swapping it out for another functional group isn’t tricky when using standard lab techniques. With this flexibility, it’s common in studies where researchers look to build new drug candidates. I’ve watched grad students reach for it during those late-night trial reactions, hoping to get yields up without awkward byproducts clogging up their results.

Aside from lab benches, its influence drifts into manufacture of dyes, flame retardants, and sometimes specialty lubricants. Bromine’s chemical qualities help inhibit fires or improve heat resistance. Both are important for industries that make cables, fabrics, or specific electronic components. As a personal anecdote, a colleague from an electronics startup once explained how their safety testing relied on bromine-rich compounds, including ones closely related to 1,6-Dibromohexane, because nothing else handled the heat quite as well.

Alongside the benefits, handling chemicals like 1,6-Dibromohexane requires serious respect. It isn’t something to splash around in an open sink. It carries hazards—skin contact can burn, inhalation risks need ventilation, and spills need prompt cleanup. Research from the National Institute for Occupational Safety and Health (NIOSH) signals the dangers of brominated organic solvents, especially with prolonged or repeated exposure. Proper gloves, goggles, and fume hoods aren’t overkill; they’re basic hygiene. Legal guides on disposal show clear routes for safe chemical waste management, keeping it out of groundwater and away from curious hands.

Looking to the future, researchers now focus on ways to replace or reduce brominated compounds. The push for greener chemistry explores plant-based feedstocks and safer halogen alternatives that won’t leave lasting marks on soil and water. Some startups already review polymer supply chains with this in mind. Investment in safer substitutes and clear labeling of materials can lower risks for workers and nearby communities. For those in the field, constant education on the health and environmental side supports progress while keeping people safe both inside and outside the lab.

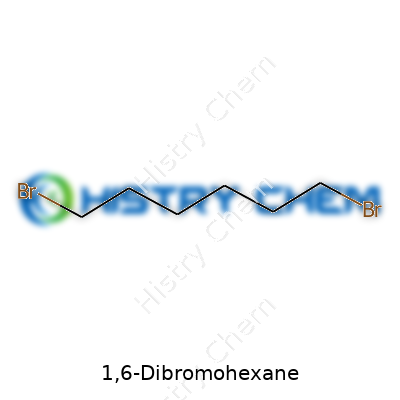

1,6-Dibromohexane carries a name that might trip up people who haven’t spent much time staring at organic chemistry textbooks. The name looks long, but it simply tells you how the molecule comes together: “hexane” is a six-carbon straight chain, and “dibromo” shows that two bromine atoms attach themselves to that chain—one at each end. Spend a little time in a college lab or flipping through a chemical catalog, and this kind of molecule pops up more often than you’d think.

In practice, 1,6-Dibromohexane ends up in real-life chemistry projects where building larger, more functional molecules matters. It’s not really trying to headline the bill on its own, but it works hard as a building block for certain drugs, plastics, and in the study of molecular electronics. The importance lies in how each part fits together—six carbons, twelve hydrogens, two bromines.

The molecular formula for 1,6-Dibromohexane is C6H12Br2. This formula stands as a basic but crucial snapshot, a shorthand for the shape and personality of the substance. Stick a bromine atom on each tip of that six-carbon chain, fill in the rest with hydrogens, and the blueprint comes to life.

Some people might overlook what this formula really tells us. Bromine weighs a lot more than hydrogen or carbon. Substances that include bromine often act quite differently than similar ones built only from carbon and hydrogen. It might seem trivial, but these two atoms drastically change how that chain behaves. In some applications, this makes 1,6-Dibromohexane uniquely reactive and good for forming links between other molecules.

Familiarity with something like C6H12Br2 goes beyond filling in a test answer for a chemistry class. Chemists working with new materials, polymers, or intermediates in the lab rely on knowing these formulas cold. Deciding to pick 1,6-Dibromohexane isn’t something that happens randomly—it happens because someone understands both what’s inside it and what it can do.

This knowledge also strengthens chemical safety. Brominated compounds often bring hazards like toxicity or environmental persistence. Simple awareness of these issues, backed by a clear understanding of what the formula means, can help researchers make better choices about storing, handling, and disposing of chemicals. Safety data sheets and regulatory agencies, such as OSHA and the EPA, mandate proper handling of brominated compounds, and proper training can prevent both lab accidents and broader pollution problems.

Newer techniques in green chemistry aim to phase out or reduce heavy halogen use, including bromine, when possible. Alternatives are coming along, but long-chain dibromoalkanes like this one still carry value in industrial settings. Education on proper use and disposal, stronger emphasis on recycling, and continued search for safer, more sustainable reactants will help limit the downsides. Teachers, laboratory managers, and researchers all play a part in this effort. Simple respect for the formula isn't just academic—it's practical, supporting more sustainable and responsible chemistry over time.

1,6-Dibromohexane shows up in many chemical labs and research facilities. It’s a clear, colorless liquid with a sharp smell. On paper, it seems simple: a chain of six carbon atoms with a bromine atom on each end. In practice, though, you have to pay attention. The chemical gets used to build bigger molecules, especially in making pharmaceuticals and specialty plastics. Its structure makes it reactive and useful, but that same reactivity brings hazards into play.

I remember seeing colleagues trip up with brominated compounds during a routine synthesis. Skin contact left bright red burns; one guy had trouble breathing for hours after a fume hood failed. The safety data sheets paint a similar picture. 1,6-Dibromohexane can irritate the skin, damage the eyes, and cause coughing or sore throat when inhaled. It barely takes a drop on bare skin to cause irritation. Eyes feel a burning pain, and lungs tighten up if the vapor builds up while working in a poorly ventilated area. Swallowing this compound causes stomach pain and vomiting.

Toxicological studies back up these reports. Animal tests show 1,6-Dibromohexane can damage organs with repeated or long-term exposure. Studies point out that certain brominated chemicals are possible carcinogens. Preliminary evidence ties long-term exposure to liver and kidney problems. Working with chemicals like this means those risks hang in the air. Chronic exposure, through the skin or breathing in fumes, adds up quickly, especially if basic safety gets ignored.

Wearing gloves and goggles isn’t just about ticking a box for compliance. Even the most experienced chemists can slip up. I always turn on the fume hood. If a fume hood fails, step away until it’s fixed. Wash exposed areas with water and strip off contaminated clothing right away. Every workplace should have clear spill procedures and plenty of fresh air moving through the lab. Supervisors should keep safety sheets in plain view and refresh training every few months. New lab workers often rush, thinking they’re safe with just a window cracked open. Brominated solvents and intermediates reward that kind of neglect with immediate health problems.

Disposal deserves more attention. Pouring leftover chemicals into the sink sends toxic bromine compounds into water supplies. Water treatment plants don’t break down 1,6-dibromohexane effectively. It can build up and threaten plants, animals, and communities. Quality control on waste handling and regular inspection of storage tanks does more than just keep the EPA happy. It keeps hazardous chemicals out of rivers and groundwater.

Getting away from hazardous solvents and intermediates makes sense, but progress stays slow. Green chemistry solutions take time and investment. In the meantime, sticking to strict storage, wearing protection, and keeping workspaces ventilated saves real lives. Manufacturers can add clear warnings and smart packaging to lower the odds of accidental contact. Safety isn’t some extra chore—it’s a crucial part of working with chemicals like 1,6-Dibromohexane.

1,6-Dibromohexane isn’t a chemical you leave lying around. Anyone who’s spent time in a lab knows some things claim your respect by their very nature. 1,6-Dibromohexane, with its strong alkylating potential and harmful vapors, falls squarely in that category. I once watched a colleague struggle with corroded shelving from a poorly stored brominated solvent—not 1,6-Dibromohexane, but a reminder that these materials bring real risks. Adequate storage isn’t about ticking off a checklist. It’s about protecting people, property, and the results of your work from unnecessary hazard.

I always recommend a dedicated, labeled storage cabinet for brominated organics. Cabinets fitted with chemical-resistant surfaces and spill containment make a huge difference. My mentor’s rule: never stack incompatible bottles. So, don’t slot this compound next to oxidizers, acids, or sodium. Leaks and accidental mixes become emergencies with brominated organics, not just inconveniences.

Room temperature might suit some materials, but experience has shown that climate-controlled storage pays off for temperature-sensitive or volatile liquids. 1,6-Dibromohexane can slowly develop pressure in sealed bottles if it gets too warm. Keep it in a cool, dry area, shielded from sunlight. I’ve seen glassware fog and even stoppers loosen on hot days because of vapor pressure changes.

Dryness isn’t just a luxury; water and brominated organics don't mix well. Moist air increases hydrolysis risks, and I watched a batch of dibromoalkane degrade into acidic byproducts because a careless labmate secured the cap loosely. The odor tipped us off first, but by then the contents turned useless. Don’t just screw down the cap—use plastic or rubber seals that actually keep moisture out.

Engineered controls, like ventilated chemical storage cabinets, protect more than one person. Airflow hoods and fume cabinets keep toxic vapors from building up. In college, our chemistry stockroom had a persistent problem with solvent odors until we replaced the standard locked case with a ventilated model. Accidental exposure dropped, and so did the unexplainable headaches staff used to report.

Make sure to place emergency spill kits, eye wash stations, and proper PPE nearby. Chemical burns and inhalation hazards with 1,6-Dibromohexane are real. Goggles, nitrile gloves, and lab coats work, but only if people use them properly. Regular training keeps safety procedures top-of-mind. I’ve seen forgetfulness and overconfidence lead to dangerous shortcuts. Ongoing reviews and clear signage help reinforce habits.

Used or expired 1,6-Dibromohexane has to go into solvents waste streams, not down the drain. Given its toxicity and persistence, any leak or spill demands immediate action. Absorbent pads and neutralizers target small mishaps; bigger problems ask for professional help. Having clear protocols gives staff the confidence to respond without delay. Early in my career, the absence of a written procedure led to confusion and wasted time during a spill; now I make sure that every work area displays step-by-step instructions.

Respecting 1,6-Dibromohexane starts with careful storage. The rules you set and follow limit personal risk and support everyone’s health. It takes more than a locked cabinet and forgotten label; it’s a mindset that every bottle carries its own story and risks. Trust in the basics: containment, climate, compatibility, and control. The payoff shows up in safer labs, healthier staff, and more reliable chemistry.

Picture a clear, colorless liquid—one that doesn’t draw attention by sight or smell, but packs a heavy punch by touch and chemistry. 1,6-Dibromohexane comes as a slick, oily substance, much like many other brominated organics I’ve seen in labs. You might notice a slight odor, just enough to remind you not to handle it carelessly. It doesn’t evaporate right away, and the liquid clings to glass, a reminder of its density.

Working with heavy liquids can be deceiving. 1,6-Dibromohexane lines up with that expectation—clocking in at about 1.6 grams per cubic centimeter at room temperature. Compare this with water, and you’ll notice a test tube tipped full of this stuff feels heavier in your hand. This density comes straight from its two bromine atoms, which bring mass and make it settle quickly if spilled in a beaker of lighter solvents.

Fire up the hot plate, and 1,6-Dibromohexane hangs tight till about 255°C before boiling off into vapor. Cold rooms, freezers—these don’t bother it much. It freezes up only at about -2°C, so it stays liquid under most storage conditions. These moderate extremes open it up to a bunch of industrial uses that need chemicals to stick around in liquid form, even with minor temperature swings in process lines or lab benches.

Try mixing it with water, and nothing happens—brominated alkanes won’t play well with polar solvents like H2O. You’ll see the two layers separate right away. Drop 1,6-Dibromohexane into something nonpolar, like diethyl ether or chloroform, and it blends right in. I’ve found this trait handy when pulling extracts or setting up organic phase reactions where polar solvents just don’t deliver.

You don’t get clouds of vapor rising from an open vial at room temperature, but give it enough heat, and the pressure builds steadily. Vapor pressure at 25°C sits around 0.02 mmHg—low enough that accidental inhalation risk drops, but not to the point you ignore fume hoods. Years working around similar compounds has taught me not to treat low volatility as a license for careless handling; brominated organics have a reputation for shifting between phases when you least expect it.

What makes 1,6-Dibromohexane more than just a chemical name on a label? Its physical properties shape how chemists use it for making polymers, linking chains, or modifying molecules in the electronics or pharmaceutical industries. For instance, that lack of water solubility means reaction clean-up involves extra effort—careful wash steps, more time on the separation table. The high boiling point lets reactions run hot without losing your main ingredient, but it also means any accidental spill is tougher to remove. Cleanup becomes more chemical than physical, often calling for strong detergents or organic solvents.

Gloves and goggles are more than window dressing when working with 1,6-Dibromohexane. Its density, stubbornness in water, and volatility at higher temperatures all point to careful, thoughtful handling. Engineers in industrial settings can lower risk with sealed pumping systems and well-ventilated workstations. Chemists and technicians need disposal protocols for brominated waste, since dumping into the sink causes more problems than it solves.

Substituting or improving processes to minimize brominated solvent waste stands out as the obvious path forward. Greener alternatives with similar chain-linking properties have started to show up in recent journal articles, pushing organic chemistry into safer territory. Tighter regulations and real-world experience tend to drive labs toward these solutions, nudging older chemicals like 1,6-Dibromohexane into specialty uses—where their mix of density, boiling point, and insolubility can’t easily be matched.

| Names | |

| Preferred IUPAC name | 1,6-dibromohexane |

| Other names |

Hexamethylene dibromide

Hexane, 1,6-dibromo- 1,6-Dibromo-n-hexane |

| Pronunciation | /waɪ.ɛn.sɪks daɪˈbrəʊ.moʊˈhɛk.seɪn/ |

| Identifiers | |

| CAS Number | 629-03-8 |

| 3D model (JSmol) | `JSMOL-1.6Dibromohexane: C(CBr)CCCCBr` |

| Beilstein Reference | 1206815 |

| ChEBI | CHEBI:51734 |

| ChEMBL | CHEMBL13737 |

| ChemSpider | 16524 |

| DrugBank | DB14174 |

| ECHA InfoCard | 11bbbab9-e1be-428a-a194-35604d4cbcd2 |

| EC Number | 207-069-8 |

| Gmelin Reference | 138182 |

| KEGG | C07344 |

| MeSH | D003965 |

| PubChem CID | 80527 |

| RTECS number | MO3850000 |

| UNII | R8B4Y5X5QW |

| UN number | UN2289 |

| CompTox Dashboard (EPA) | DTXSID0021773 |

| Properties | |

| Chemical formula | C6H12Br2 |

| Molar mass | 271.95 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Odorless |

| Density | 1.394 g/mL at 25 °C (lit.) |

| Solubility in water | Insoluble |

| log P | 2.94 |

| Vapor pressure | 0.0081 mmHg (25 °C) |

| Acidity (pKa) | 14.0 |

| Magnetic susceptibility (χ) | -7.9e-6 cm³/mol |

| Refractive index (nD) | 1.500 |

| Viscosity | 2.18 cP (25°C) |

| Dipole moment | 2.5197 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 386.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -110.8 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3918.8 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS06,GHS07 |

| Signal word | Warning |

| Hazard statements | H302 + H312 + H332: Harmful if swallowed, in contact with skin or if inhaled. |

| Precautionary statements | P210, P261, P280, P303+P361+P353, P305+P351+P338, P405, P501 |

| NFPA 704 (fire diamond) | 1-2-0 |

| Flash point | 97 °C |

| Autoignition temperature | 355 °C |

| Explosive limits | Explosive limits: 0.9–6.4% |

| Lethal dose or concentration | LD50 oral rat 910 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50 = 795 mg/kg |

| NIOSH | TT2975000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 100 mg |

| IDLH (Immediate danger) | IDLH: 50 ppm |

| Related compounds | |

| Related compounds |

1,4-Dibromobutane

1,5-Dibromopentane 1,8-Dibromooctane 1,6-Dichlorohexane 1,6-Diiodohexane Hexane |