Chemistry’s story with 1,4-cyclohexanedimethanol kicked off decades back, as polymer scientists searched for new building blocks to advance plastics and fibers. Researchers saw the unique structure of this diol—two alcohol groups on a cyclohexane ring—offering properties regular glycols didn’t provide. Early work focused on hydrogenating aromatics, and gradually, as industry demand for better polyesters climbed, factories produced more of it, shifting from lab curiosity into large-scale production. The journey closely mirrored the broader shift in chemical research, where practical solutions to daily challenges drove innovation, pushing companies and labs to dig deeper for compounds with better durability, performance, and processing ease. By the time PET plastics and new-age fibers took off, this molecule had already carved a niche as a critical monomer shaping industrial chemistry.

At its core, 1,4-cyclohexanedimethanol brings together cyclohexane’s stability and two methanol branches, packaged as a crystalline substance. The chemical formula is C8H16O2, and it often comes as a white to off-white powder or granule, depending on the grade. Industries lean on it for its efficient reactivity, simple integration into current processes, and compatibility with common catalysts. The world of polyester and plastic additives relies heavily here—CHDM delivers specific benefits in toughness, clarity, and weather resistance that widen its reach beyond standard alternatives.

This dihydric alcohol has a melting point near 87°C, and its boiling point lands around 295°C. CHDM dissolves well in alcohols and some glycols, but water and most hydrocarbons barely budge it. The two hydroxyl groups open doors for esterification, making it a natural fit for polyester synthesis. The cyclohexane ring shields against UV and chemical attack, extending performance in coatings and engineered plastics. On the bench, the substance feels waxy or grainy, with low odor and negligible volatility at room temperature, making it manageable during manufacturing and handling.

Manufacturers typically offer CHDM at purity levels above 99%, verified by gas chromatography and delivered in moisture-proof sacks or drums. Labels must show batch numbers, purity percentages, and storage advice, owing to sensitivity to moisture and oxidation. Storage practices ask for cool, dry, and ventilated spaces, and safety data sheets come packed with hazard codes and handling guidelines required by regulations like REACH in Europe and the EPA’s rules in the US. End users and reseller facilities both check for these specs before accepting a delivery, since slight variances can shift downstream quality.

Production usually starts from dimethyl terephthalate, which undergoes hydrogenation over a metal catalyst, transforming the aromatic ring into a cyclohexane backbone. The intermediate then reacts with methanol, cleaving the ester bonds and releasing methanol as a byproduct. Plants optimize temperatures and pressures carefully, since yields and purity tie closely to keeping side reactions in check. Catalyst recycling and waste minimization factor heavily, especially with tightening environmental laws. Some facilities explore alternative feedstocks, hoping to find greener, cheaper, or safer ways to make the product. Though most preparation flows draw from petrochemical sources today, rising interest in bio-based hydrogenation could reshape this landscape.

1,4-Cyclohexanedimethanol readily participates in condensation with carboxylic acids to form esters, a mainstay step in polyester and resin synthesis. The cycloaliphatic structure enhances thermal stability and chemical resistance of final materials. Other reactions involve conversion with isocyanates for specialized urethanes, or grafting onto acrylate backbones for advanced coatings. Its alcohol groups are tough against oxidation yet handle substitution reactions without complex conditions, letting chemists tweak physical properties for niche applications like toughened engineering plastics or high-gloss films. This flexibility stands out to those developing next-generation polymers or adhesives.

Chemists and industry alike know this compound by several labels. Besides 1,4-cyclohexanedimethanol, you’ll see CHDM and 1,4-bis(hydroxymethyl)cyclohexane, reflecting its formal IUPAC name. Some suppliers use product codes such as EINECS 212-012-0 or CAS No. 105-08-8. Occasionally, legacy or in-house names pop up, but global commerce largely settles on CHDM for brevity and clarity.

Even though CHDM carries low immediate toxicity, safe handling matters. Inhalation or prolonged skin contact may irritate sensitive individuals. Plants and labs require protective gloves and eyewear, especially during large-scale transfers or compound mixing, to sidestep skin and eye exposure. Dust control systems keep airborne levels within regulatory limits, and spills are swept up while avoiding water drains, given persistence in aquatic environments. Emergency kits and eyewash stations back up these procedures. Training tackles both accident prevention and emergency response, as the industry’s push for zero-incident workspaces gains momentum.

Much of the global output flows into polyester production, making bottles, films, and textile fibers stronger and clearer. Resin systems for high-durability coatings or automotive plastic parts build in CHDM for its weathering and scratch resilience. Electrical insulation, adhesives, and specialty urethane panels also carry CHDM-based polymers, riding on their impressive balance of flexibility and endurance. In these fields, performance demands keep rising, and this compound’s versatility lets engineers meet targets in strict regulatory environments, whether for food contact materials or emissions compliance.

Current R&D circles around greener manufacturing and novel formulations. Investigators chase bio-based feedstocks and improved catalysts to slash waste and energy use. The integration of CHDM into new co-polyester blends attracts interest, especially in packaging and medical devices needing clarity, sterilizability, and strength without added plasticizers. Teams explore processing refinements to cut cycle time, reduce material defects, and extend product lifetime. Academic and corporate researchers publish steadily on reaction mechanisms, structure-property links, and recycling methods that could close the loop on polymer products.

Toxicologists put CHDM through a long list of acute and chronic studies. Data suggest minimal risk at standard occupational exposures, provided safety guidelines stay in place. Animal tests over the years show low rates of systemic toxicity, mutagenicity, and skin sensitization. Wastewater and soil fate studies, though, highlight slow natural degradation, prompting concern in regions with heavy manufacturing density. Analysts encourage ongoing biomonitoring and environmental testing, not just during production but across the lifecycle of CHDM-based materials, aiming to head off problems that could show up years down the line.

Demand for CHDM tracks alongside global needs for recyclable, high-performance plastics and fibers. Biopolymer innovations, tougher emission standards, and a growing green chemistry movement all provide new directions for improving and expanding CHDM’s role. The search for drop-in bio-alternatives and circular economy solutions draws investment into process upgrades and feedstock diversification. Researchers working on upcycling old PET have started exploring CHDM’s unique structural contributions, envisioning both product upgrades and reduced waste. In the years ahead, success hinges on blending chemistry breakthroughs with community accountability—balancing higher efficiency, lower cost, and minimal impact. The story of 1,4-cyclohexanedimethanol remains far from finished, and its ongoing evolution reflects both the possibilities and challenges facing the entire material sciences field.

1,4-Cyclohexanedimethanol, often just called CHDM, floats quietly under the radar in our daily lives. Most people don’t recognize it, but anyone who spends time around plastics, resins, or household products has come across it in some shape or form. I’ve seen how this chemical makes its mark, especially working alongside folks in manufacturing and consumer goods. Its real strength comes from the way it helps create sturdy, clear plastics that don’t shatter easily and keep their shape.

Manufacturers turn to CHDM primarily when producing copolyester plastics. These are the kinds of plastics used in water bottles, electronics casings, food packaging—even the lenses on your sunglasses. Polyethylene terephthalate glycol (PETG) relies on it, and so does a growing number of packaging alternatives that don’t grow brittle over time. As someone who’s handled plenty of consumer products, I notice the trend: folks want better clarity and durability without the danger of breakage or leaching chemicals, and CHDM fits these needs.

Research shows that CHDM-based plastics avoid yellowing and offer flexibility under stress. In a time when plastic waste draws scrutiny, there’s an effort to create items that last longer and don’t crack right away. This appeals to companies wanting to reduce returns and waste. More than a sales pitch, these qualities make a difference for people and the environment.

CHDM’s impact stretches far past bottles or containers. In the coatings sector, it improves resistance to scratches and weathering. You see the results on painted appliances or metal cans. The chemical structure lets coatings stay glossy and resilient after years of touch and abrasion. Textile fibers also benefit, especially in carpets and performance fabrics, where strength and shape retention matter. Polyester fibers spun from CHDM-based monomers can handle repeated laundering and foot traffic without looking tired.

Transparency matters, not only for manufacturers but for consumers. Agencies like the U.S. Environmental Protection Agency review CHDM’s safety profile regularly. Current research suggests CHDM doesn’t pose the same risks as notorious chemicals like bisphenol A (BPA). Still, environmental and health experts keep their eyes open for possible long-term impacts, especially as recycling rates for plastics stall in many regions. Without responsible end-of-life management, all the durability in the world won’t offset the bigger pollution problem. Community efforts and investments in advanced recycling promise some relief, but progress moves slowly.

The answer won’t come from simply banning chemicals or demanding instant replacements. Drawing from my time talking with chemists and product designers, I’ve seen value in collaboration between industry, public health researchers, and regulators. This approach brings forward safer, longer-lasting materials and clearer labeling, so shoppers can make choices with confidence. CHDM’s track record so far suggests a useful future—if the people making and using it keep pushing for better oversight and smarter waste handling. Looking ahead, making plastics with CHDM more recyclable and more transparent in labeling helps everyone.

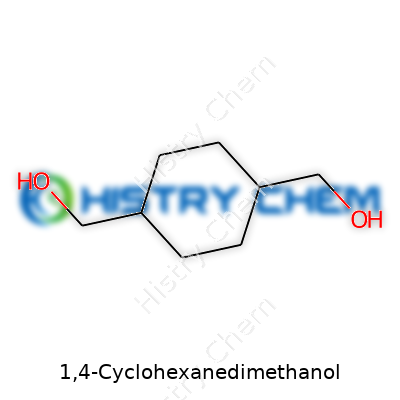

1,4-Cyclohexanedimethanol, often called CHDM, draws interest from chemists and manufacturers alike. Its chemical structure starts with a cyclohexane ring—picture a six-carbon ring shaped like a slightly puckered hexagon. Attached to this ring, at carbons 1 and 4, are two methanol groups. Each methanol group features a carbon bonded to an alcohol (–CH2OH), branching out from opposite sides of the ring. It gives the molecule some bulk and makes for interesting three-dimensional geometry. For reference, its molecular formula reads as C8H16O2. The most approachable structure drawing would show a cyclohexane ring with two –CH2OH arms sticking out at the top and the bottom.

Looking at familiar plastics, especially water bottles or clear packaging, the tough and lightweight qualities tie back to molecules like CHDM. Its chemical structure creates a strong, flexible backbone for certain polyesters, including PETG (polyethylene terephthalate glycol-modified). Those two hydroxymethyl groups on the ring aren’t just decorative; they serve as reactive sites. Manufacturers use them to make long polymer chains by connecting them with acids or other diacids. The cyclohexane ring provides rigidity, while the methanol groups bring in some flexibility. This balance gives rise to plastics that don’t shatter easily and show off glass-like clarity.

As someone who’s handled soda bottles or smartphone cases, that click or bounce isn’t just a trick of design—it’s rooted in how molecules like CHDM build shock resistance into the material. In the lab, trying to break down a PETG sample or looking at how it interacts with dyes and coatings, I’ve seen how these methanol-arms welcome chemical reactions that plastics without such groups struggle to achieve. That chemical invitation opens doors for recyclability, printability, and easier coloring. It also means bottles don’t suddenly go brittle in the cold or melt in a warm delivery truck.

No building block comes without its set of worries. Some questions surround the raw materials that go into making CHDM, often sourced from fossil fuels. If supply chains lose oversight, environmental impact ramps up. Research points to resource-heavy production steps and carbon emissions as legitimate issues, especially as demand for durable plastics rises. There’s also concern over microplastics and end-of-life disposal for polymers made with CHDM. Scientists investigate biodegradation rates and recyclability, trying to tip the balance in favor of a cleaner outcome.

Improving CHDM’s footprint starts with pursuing greener chemistry. By shifting to bio-based cyclohexane sources, manufacturers can cut ties to oil and gas. Pilots have tested renewable feedstocks like glucose or plant sugars for synthesizing cyclohexane rings, and though scaling up brings hurdles, it’s progress worth celebrating. On the consumer end, pushing for clear recycling marks and better collection systems helps keep these valuable materials in play, not in landfills. Policy makers and scientists can work together by funding research into alternatives or enhancing current recycling techniques, blending tough plastics with sustainability.

1,4-Cyclohexanedimethanol, often known in the plastics and resin world as CHDM, plays a big role in making copolyesters tougher and more impact-resistant. It shows up in the structure of some water bottles, food packaging, and even in the clear trays used to display fruit in grocery stores. I’ve seen plenty of stories float around online about “hidden” chemicals in daily products, but naming something chemical-sounding like CHDM as toxic doesn’t do anyone any favors. It’s worth digging into what the science says and applying a bit of common sense.

Articles that toss around the label “toxic” without explanation tend to stir up worry, even when the facts tell a calmer story. According to both the European Chemicals Agency and the U.S. Environmental Protection Agency, CHDM scores a low hazard profile for humans during normal use. Industry studies and chemical safety assessments show that it doesn’t usually lead to immediate health effects just by touching or using items made with it. Working with large amounts during chemical production, especially as a fine mist or dust, brings its own risks, as with any industrial substance — eye and skin irritation, mostly. Breathing in high levels can irritate the airways. But that’s a concern for factory floors, not kitchen tables.

Most people encounter CHDM mixed into the backbone of sturdy plastics. This means it’s chemically locked into the final product. I’ve met parents who worry about plastic drink bottles leaching weird chemicals, thanks to news stories about BPA and phthalates. But regulatory bodies like the FDA and Health Canada have done migration testing on plastics containing CHDM and found levels far below anything considered risky to human health. Migration tests really matter here — they place plastics in hot, acidic, or fatty foods to see if anything sneaks out. Manufacturers aiming for safety certificates run these tests as part of product approval.

No chemical is totally harmless if handled the wrong way. Factory workers or transporters who deal with pure CHDM need basics: gloves, goggles, and good ventilation. Spills should get cleaned before dust can build up. In the rare case of a spill, safety data sheets call for soap, water, and a mop, not a hazmat suit. Local environmental releases shouldn’t cause panic, but accidental dumping can harm organisms in waterways if it’s widespread enough. Regular lab tests check levels in workplace air and water just to be safe.

People ask, “Why use CHDM if there’s any risk at all?” It comes down to trade-offs. Plastics made with CHDM end up safer to use long-term, needing fewer plasticizers and withstanding rough handling better. Regulators update their safety targets as new studies come out, and consumer groups push for transparency. Better labeling and public science outreach would go a long way to helping people make informed choices. I watch these conversations spark online every year, and I believe curiosity beats fear every time. Let’s keep testing, keep reading, and keep asking questions about anything that touches our food, water, or hands — chemicals included.

Most folks who handle specialty chemicals day to day know the margin for error stays narrow. I’ve spent enough time around industrial storerooms and smaller labs to see things go sideways just because a chemical ended up by a sunny window or open container. 1,4-Cyclohexanedimethanol—often used to make polyesters and resins—calls for the same kind of careful attention as any mid-level reactive organic. Storing it right doesn’t just keep the workplace safe. It also keeps the chemical useful, which saves money and supports product quality.

1,4-Cyclohexanedimethanol attracts moisture from the air and dissolves into clear, somewhat sticky lumps if exposed. Its solid form gives a false sense of security, since improper handling can still introduce contaminants or degrade its quality. Temperatures matter, too. Temperatures that run too warm can stress stability and speed up unwanted reactions. Humidity, direct sunlight, and dusty conditions add more complications.

I’ve seen firsthand what a messy storeroom can do. Unlabeled bins and sagging bags collect dust. Someone grabs what looks like clean chemical, but it’s been opened too long or let water seep in. Unplanned downtime, product rejection, and sometimes recalls follow from small storage mistakes.

Anyone working with 1,4-Cyclohexanedimethanol should stick with a few straightforward practices. Good storage needs proper containers. I recommend tight-sealing, corrosion-resistant drums or pails. Wide temperature swings inside a warehouse—hot summers, chilly winters—undercut purity and possibly increase fire risk. Store this chemical as close to room temperature as possible, usually between 20 and 30°C, unless your supplier tells you otherwise. Don’t set drums near heat sources or in direct light.

Moisture control matters. Store containers slightly off the concrete floor, maybe on wooden pallets, to avoid temperature gradients and spills. Keep containers shut tightly unless you’re measuring out product. A dry, well-ventilated space gives you the biggest safety margin—minimizes inhalation, limits mold and corrosion, and discourages pests.

One mistake sticks in my head from a client’s facility: all the drums looked identical, but two rows contained completely different chemicals. Legible, durable labels on every container and shelf really do make the difference—no guessing needed, no time wasted. Beyond labels, give everyone a desk-free chance to refresh on safe handling, spill response, and how to spot early signs of degradation.

Broken bags, cracked lids, or residue around seals tell you it’s time to remove that batch. A quick visual check every time you walk by helps more than inspection paperwork months later. Have spill kits and absorbent pads visible, not locked away. Teach staff how to use them before they need to.

The foundation of safe storage comes down to consistency and clear habits. Small investments in good shelving, diligent labeling, and control of heat and moisture spare everyone trouble. Product integrity means less risk for everyone downstream—customers, coworkers, and even the community. Secure storage, paired with routine checks and basic training, helps any shop or lab avoid accidents, cut costs, and deliver safe, high-quality goods.

1,4-Cyclohexanedimethanol shows up as a solid at room temperature, often melting right around 85°C. In a typical lab, the off-white, crystalline appearance stands out. Science calls it CHDM for short, and chemistry folks rely on its firm consistency before heating. Unlike some other diols, it doesn't clump or get sticky unless placed in much warmer conditions. This marks it as easier to handle and weigh than the oily stuff like glycerol or propylene glycol.

Density gives some clues to its feel and weight in a flask. CHDM clocks in close to 1.06 grams per cubic centimeter—so it sinks in water, but not as fast as metal salts. Its moderate density lets suppliers pack it in bags or bottles without worrying about serious crushing.

The water solubility might surprise some. CHDM dissolves in water at room temperature, but only up to about 4 grams per liter. Try mixing more and the rest just settles down, showing that it likes sticking with itself in cooler settings. Once you add heat, you can coax it into solution with a bit more ease, but you won't get anywhere near the solubility of white sugar or table salt. People looking for a real water-loving chemical might lean on ethylene glycol instead.

No sharp odor hits the nose with CHDM, which can't be said for many of its cousins in the alcohol family. In the time I've handled the powder, I noticed that it feels oddly soft to the fingertips, almost like rubbing talc or cornstarch. Makeup producers and plastics engineers appreciate this because it doesn’t rough up machines or scatter fine dust around. Unlike naphthalene or some aromatic alcohols, CHDM avoids headaches from fumes.

For product manufacturers, a clear melt point matters. CHDM softens just below 90°C and gets fluid rather quickly after that. Its boiling point doesn’t come into play during regular polymer work, since it tends to decompose before vaporizing—something to keep in mind for anyone curious about distillation. That’s why most CHDM modifications run below 200°C. I remember a process engineer emphasizing that heating above this leads to side reactions, gunk, and ruined batches. Keeping tight tabs on temperature saves time and costly cleanups down the road.

CHDM stands up to air and light. Storage on open shelves doesn’t lead to sticky messes or darkening. In my experience, this stability lets companies keep it on hand for months, only worrying about humidity and stray contaminants.

Why bother looking at all these numbers and descriptions? For one, the melting and solubility matter a lot to the polyester and polyurethane makers. CHDM joins up with acids to build tough, clear plastics—these go into water bottles, durable fibers, and specialty films. The solid form makes dosing and shipping safe. Water's reluctance to dissolve chunky loads of CHDM keeps blending steps controlled and repeatable. Users know to watch out for sudden solubility changes at higher temperatures, which can affect mixing or product texture.

Low odor and gentle handling matter for anyone making consumer goods. Worker safety managers count on the calm aromatics and solid feel, lowering the risk of irritation and stress. Texture clues workers in whether moisture has snuck into the product. Powder that clumps up signals the need to tighten storage conditions.

Some manufacturers push for finer granulation, which shrinks clumping risk in humid factories. Others look at better packaging barriers, keeping moisture out. Some blend in desiccants or store under nitrogen. Sharing best practices through technical groups lets new producers avoid common pitfalls. Every choice comes back to understanding and respecting the physical quirks CHDM brings to the table.

| Names | |

| Preferred IUPAC name | bis(hydroxymethyl)cyclohexane |

| Other names |

CHDM

1,4-Bis(hydroxymethyl)cyclohexane Dimethylolcyclohexane Cyclohexane-1,4-diyldimethanol |

| Pronunciation | /ˈwʌn.fɔːr saɪ.kloʊˌhɛk.sən.daɪˈmɛθə.nɒl/ |

| Identifiers | |

| CAS Number | 105-08-8 |

| Beilstein Reference | 408320 |

| ChEBI | CHEBI:52776 |

| ChEMBL | CHEMBL16601 |

| ChemSpider | 10304 |

| DrugBank | DB01855 |

| ECHA InfoCard | 13b42f99-2e8b-433b-9b48-f403ba22f81b |

| EC Number | 219-941-5 |

| Gmelin Reference | 77866 |

| KEGG | C06561 |

| MeSH | D003527 |

| PubChem CID | 10909 |

| RTECS number | GV2800000 |

| UNII | 4B6A2L6S1N |

| UN number | Not regulated |

| CompTox Dashboard (EPA) | `DTXSID2020187` |

| Properties | |

| Chemical formula | C8H16O2 |

| Molar mass | 142.20 g/mol |

| Appearance | White solid |

| Odor | Odorless |

| Density | 1.06 g/cm³ |

| Solubility in water | soluble |

| log P | 0.81 |

| Vapor pressure | 0.01 mmHg (20°C) |

| Acidity (pKa) | 15.19 |

| Magnetic susceptibility (χ) | -61.7·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.462 |

| Viscosity | 15.8 mPa·s at 75 °C |

| Dipole moment | 2.34 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 290.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -358.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4095 kJ mol⁻¹ |

| Hazards | |

| Main hazards | May cause respiratory irritation. Causes serious eye irritation. Causes skin irritation. |

| GHS labelling | GHS07 Warning |

| Pictograms | GHS07,GHS08 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | P210, P233, P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1,1,0 |

| Flash point | 124 °C (255 °F; 397 K) |

| Autoignition temperature | 385 °C |

| Lethal dose or concentration | LD50 oral rat 5,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): >5,000 mg/kg (oral, rat) |

| NIOSH | MF8575000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 10 ppm |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Cyclohexanedimethanol

1,2-Cyclohexanedimethanol 1,4-Cyclohexanedicarboxylic acid Cyclohexanediol Dimethyl terephthalate |