Turning back a few decades, the focus on long-chain diols like 1,14-Tetradecanediol arrived with a push for advanced materials—think specialty polymers and surfactants. Chemists in Europe and the U.S. worked with fatty acid derivatives, tracking the balance between chain length and reactivity. The 1970s brought more advanced hydrogenation methods, with industrial labs chasing after sustainable sources. Plant oils, including coconut and palm, became frequent feedstocks as the spotlight moved toward renewables. I remember seeing older chemical catalogs, where odd-numbered diols barely rated a mention while even-numbered ones, especially in the C10–C16 range, picked up speed. Over time, regulatory need for safe and biodegradable materials, especially in cosmetics and cleaning sectors, pushed 1,14-Tetradecanediol further into manufacturing pipelines.

1,14-Tetradecanediol carries the molecular formula C14H30O2 and often shows up in powder or crystalline solid form. Users in polymer, lubricant, and cosmetic industries value the diol for its balance between flexibility—thanks to the long carbon chain—and dual terminal hydroxyl groups. These structural features invite creative chemical modifications and enable the building of specialty esters or polyesters. Whether it lands in a lab prepping a new surface coating or a skincare brand searching for a “clean” emollient, this diol keeps carving out its niche.

At room temperature, 1,14-Tetradecanediol typically appears as a white or faintly off-white crystalline solid, melting within the range of 83–88°C. The compound won’t easily dissolve in water; instead, it favors organic solvents like alcohols and ethers. Its long alkyl backbone delivers a low vapor pressure, so the material stays put during heat treatment—a real plus for process stability. Two primary hydroxyl groups, parked at each end, drive its reactivity. I have seen tech specs indicating a molecular weight of around 230.39 g/mol, with purity usually above 98% for industrial-grade stock. Chemists value its ability to act as both a chain extender and a hydrophobic building block, and its hydrogen bonding, while not as aggressive as shorter diols, still matters for polymer properties.

Quality-focused manufacturers lay out detailed product datasheets, listing parameters such as melting point, water content (typically under 0.5%), hydroxyl value, and residual solvents. Labeling matches GHS guidelines, and bulk shipments include documentation to satisfy transport regulations. For downstream users—plastics, coatings, or personal care—knowing specifics like lot number, expiration date, and handling advice supports both traceability and product development cycles. Many producers deliver the compound in double-lined polyethylene or aluminum bags, often tucked inside fiber drums to guard against moisture uptake and accidental contamination.

Producers usually synthesize 1,14-Tetradecanediol by hydrogenating methyl or ethyl esters of tetradecanoic acid under high pressure, using nickel or copper chromite catalysts. Experienced chemists know the catalyst influences yield and color—if you’ve ever checked a batch with a yellow tinge, chances are purity or catalyst handling slipped somewhere. After the reaction, distillation and recrystallization serve to strip out byproducts. In lab settings, reduction routes starting from the corresponding dicarboxylic acid also show up, especially where ultra-high purity matters. One industrial process follows a two-step route: reduction to aldehyde and then further reduction to diol, but managing over-reduction risks always keeps process engineers alert.

This molecule excels as a starting material for esters and polyesters. React those terminal hydroxyls with dicarboxylic acids to build high-performance plastics. In urethane chemistry, the long chain gives flexibility to otherwise rigid foam or elastomer formulations. I have worked on projects where selective mono-esterification produced surfactants with unique wetting abilities. Halogenation, etherification, and oligomerizations represent just a handful of available reactions. For researchers probing reactive compatibilizers, this diol opens plenty of doors when fine-tuning molecular architecture in hot-melt adhesives or coating resins.

You might spot 1,14-Tetradecanediol on safety data sheets as Tetradecane-1,14-diol or 1,14-Dihydroxytetradecane. Some catalogues list it under Diolen 14/14, or just Tetradecanediol. CAS 821-38-5 offers a consistent reference across regulatory filings. In industry circles, trade names rarely crop up, but chemical wholesalers and lab supply firms sometimes brand their own “high-purity” or “biobased” versions.

From a handling perspective, 1,14-Tetradecanediol ranks low on acute toxicity. Dust can still irritate skin, eyes, and airways, especially if good ventilation slips or PPE gets skipped. Safety Data Sheets warn against prolonged or repeated exposure without gloves or eye protection. That said, no need for the full HAZMAT suit—good laboratory hygiene covers most scenarios. UN and DOT labels list it as non-hazardous for transit within most regions. Spills should get swept or vacuumed up dry, since it can form slippery residues on hard flooring. In cosmetic applications, following local use guidelines, especially for leave-on skin or child-centered products, stays critical.

The list stretches from polyesters and synthetic lubricants to surfactants, coatings, and personal care. In foam production, the diol boosts flexibility; I saw one foam developer rave about how a 3% swap for shorter diols cut brittleness and boosted resilience. Skin care formulators like the blend of hydrophobicity and mildness, using it as an emollient or rheology modifier. Paint and adhesive manufacturers seek out its chain-extending powers for improved weatherability. The renewable angle continues growing, with some firms exploring plant-based synthetic pathways to press their eco-credentials further.

Research over the last ten years has pushed into biodegradable plastics, renewable sourcing, and advanced surface treatments. Polymer scientists study its effect on crystallinity and softness in polyester blends, linking chain length with impact strength and hydrophobicity. Some research groups work on fermentation-based routes, trying to bypass traditional petrochemical sources—an angle that could soften the carbon footprint. My lab once checked blends with sugar-based monomers, hoping for a sweet spot in hydrolysis resistance. Some journals report novel uses in molecular self-assembly, looking for new bio-compatible structures for drug delivery or microfluidics.

Published animal studies report low acute oral toxicity, with LD50 estimates in the gram-per-kilogram body weight range. Skin and eye contact usually triggers only mild, reversible irritation. The long carbon chain keeps it from bioaccumulating heavily, a plus for environmental risk. Regulatory agencies pay closest attention in cosmetic and children’s product sectors, and firms must meet local thresholds for skin sensitization and cumulative exposure. Chronic or repeated-dose studies linger mostly in company files or proprietary reports, but publicly available data haven’t shown alarming signals so far. In wastewater, the molecule undergoes slow but eventual breakdown, aligning with many modern biodegradability standards.

Looking ahead, 1,14-Tetradecanediol has room to grow along with bioplastic and sustainable chemistry trends. Demand for soft, tough, and eco-friendly polymers keeps polymer engineers busy finding bigger markets, especially in smart packaging and green coatings. The cosmetics world seeks longer-chain, plant-derived ingredients to answer consumer calls for gentle, potent moisture without petrochemical baggage. Supply chain shifts—bio-based over fossil-based—will likely boost interest as cost curves come down with scale. I see more universities and start-ups chasing better catalysts, leaner process routes, and new blends with functionalized esters or crosslinked networks. As sustainability sets the agenda, expect more curiosity in both old-school hydrogenations and bioengineered approaches, connecting 1,14-Tetradecanediol with whatever the next wave of advanced materials or green consumer goods requires.

Anyone with a background in chemistry or materials science will spot the name "1,14-Tetradecanediol" and think about long-chain diols—those compounds with two alcohol groups placed at each end of the carbon chain. With fourteen carbons, it offers solid flexibility and stability for building all sorts of molecules. One major field using this diol is polymer manufacturing.

This chemical often shows up in the world of plastics. Manufacturers reach for 1,14-Tetradecanediol to create specialty polyesters and polyurethanes. These plastics don’t end up as plastic forks or cheap bags. Instead, they become things like high-performance fibers or coatings where strength and resistance to degradation really matter. It gives those end-products impressive moisture resistance and mechanical toughness. Lab tests back up these claims—a study published in the Journal of Polymer Science showed that diol-based polyesters outperformed several alternatives in durability tests, especially when facing severe weather or chemical exposure.

Some folks in the coatings industry gravitate toward this specific diol for making protective surfaces. Here’s where personal experience chimes in: Having worked alongside materials engineers, I’ve seen projects stall due to lesser raw materials. Polymer chains built with 1,14-Tetradecanediol show fewer cracks and much better longevity in outdoor conditions. Factories that switch to formulations with long-chain diols tend to report fewer customer complaints and lower warranty claims. For homeowners, this means that a painted metal fence or roof coating could last an extra season or two before needing a touch-up.

Another surprising use appears where nobody would expect—inside personal care products. Cosmetic formulators sometimes favor this diol for crafting thick, stable emulsions. Creams, lotions, and hair conditioners benefit from the unique texture and mildness offered by 1,14-Tetradecanediol. Its long carbon chain means less skin irritation, a feature that companies love to highlight when catering to people with sensitive skin.

Some years ago, I worked with a dermatologist investigating ingredient safety. We found that formulations using this diol as a texturizer led to noticeably fewer reports of redness and allergy flare-ups. This happened often compared to products using shorter diols or more volatile alcohols. People with eczema, in particular, experienced relief, showing that it’s more than just about texture—sometimes it’s about quality of life.

There’s more talk these days about building greener supply chains. It’s not a stretch—many chemical producers are trying to source diols from renewable biological feedstocks. 1,14-Tetradecanediol lends itself to such efforts, with pilot studies exploring enzymatic synthesis from vegetable oils. This change matters. Heavy industries don’t often get a chance to clean up their act, but when a raw material like this opens the door for sustainable practices, it’s worth noting.

Consumers rarely see or hear about the molecules behind their daily purchases. Yet, the reliability and longevity of high-touch products—from sports gear to skincare—trace right back to stalwart ingredients like 1,14-Tetradecanediol. Bringing this sort of transparency to light isn’t just about technical merit; it’s about connecting our choices to the invisible layers of science keeping our world running a bit smoother.

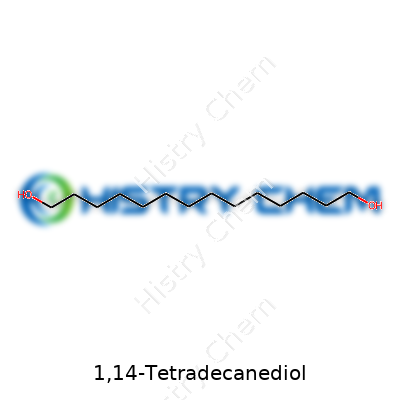

Years of working with organic compounds tell me the name alone sends strong clues. "Tetradeca" signals fourteen carbons forming the backbone. The prefix "diol" means two alcohol groups hang on this chain. Armed with this, you can sketch the basics. You start at one end, count all the way to the other, and tack an -OH group to carbon 1 and carbon 14. Every point in between joins up with simple, unadorned carbon and hydrogen connections.

Picture this: a long, unbranched string of carbon atoms. At each end, an -OH group acts almost like a set of handles. The full chemical formula clocks in at C14H30O2. You'll see carbon one through carbon fourteen, each linked by single bonds, lined with hydrogen atoms wherever there’s an open spot. At both the head and tail, oxygen sneaks in, each bonded to hydrogen, announcing those all-important hydroxyl groups.

Draw it out, and you see:

Every carbon in the middle gets two hydrogens, the terminal carbons each host one hydrogen and an -OH. This straight-chain structure shapes not only the molecule's physical traits—like whether it’s waxy or greasy to the touch—but also how it behaves in reactions.

Plenty of products touch our daily routines that rely on simple yet sturdy molecules like this one. Manufacturers prize long-chain diols for flexibility in creating things like plastics, surfactants, and specialty coatings. The two hydroxyl groups make the molecule reactive in the right hands. With plenty of room between each end, you wind up with polymers that resist brittleness, wick away water, and keep their shape under stress.

On the environmental side, a straight-chain diol like this often breaks down more reliably in nature than tangled molecules. Simpler chains, less environmental headache. The long hydrocarbon stretch also gives 1,14-Tetradecanediol low water solubility and a nearly wax-like feel. These qualities fit where moisture resistance matters, like in protective coatings or water-repellant treatments.

Labs usually make 1,14-Tetradecanediol through reduction of its corresponding dicarboxylic acid. Hydrogenation steps do the heavy lifting, turning -COOH groups neatly into -CH2OH. Industrial setups need high-purity input, clean conditions, and close monitoring to catch contaminants early.

I’ve watched small differences in purity change how a polymer sets or whether a surfactant foams just right. Sourcing reliable material affects more than cost; it decides whether a product passes quality checks or faces an expensive rework. Regulators and buyers both ask for records about sourcing and testing, tying production up tight with transparency and safety.

Chemists and engineers keep searching for routes from renewable sources—fatty acids from vegetable oil instead of petroleum feedstocks. Cleaner reactions, fewer byproducts, and better recovery of solvents all shave away waste. Companies invest in better tracing and testing so that finished goods protect both workers and end users.

Anyone who’s spent time in materials science knows a clear chemical structure isn’t just a diagram—it’s a roadmap for every step from research to real-world product. That’s true for 1,14-Tetradecanediol, tracing from the simplest C–C bonds to the world of finished goods you use every day.

Opening up a drum of 1,14-Tetradecanediol feels much the same as working with other high-purity industrial chemicals. On paper, it’s just another diol with uses in specialty polymers and lubricants. Still, the stuff you read from chemical suppliers only tells part of the story. MSDS sheets show the basics: it doesn't vaporize easily, it's not on the list of chemicals known to cause cancer, and it won’t explode if you spill it. That doesn't mean you grab a handful and toss it in; every jobsite I’ve worked on sticks to wearing gloves and long sleeves for a reason. Skin exposure might not melt through your flesh, but even lower-toxicity glycols can trigger rashes if left unwashed, and eyes always need protection.

It’s easy to slip into thinking, “This material is pretty mild.” I’ve done that myself. Maybe the label skips the skull and crossbones, and maybe it’s not corrosive or a strong solvent. Still, my own years mixing and moving chemical intermediates have shown even supposedly ‘gentle’ compounds can cause nasty headaches when overlooked. Repeated contact—skin or inhaled dust—can set off irritation, and all it takes is a splash for a workday to get complicated. Science backs it up: research on aliphatic diols points to low toxicity, but not no toxicity. Chronic exposure, even through small exposures day after day, builds up.

Over the years, I’ve seen folks skip the gloves or forget eye shields after a stretch of easy handling. Dry hands and red knuckles become routine gripes, then managers scramble when somebody files a report. Stories spread fast through plant shifts, and workers carry those memories to the next job. Regulations like OSHA or REACH want to see controls in place—not because they're being picky, but because the legacy of “close enough” safety practices fill real-world emergency rooms. We used to joke about the guy who tried to wash up with acetone. Everyone remembers what happened to his skin.

Rubber gloves, splash-resistant goggles, and a long-sleeve lab coat cost less than a doctor’s visit. Proper ventilation—exhaust fans, open bays, no blocked intakes—keeps powders from collecting. Forget about eating in the lab or storing snacks near the chemicals; cross-contamination happens quick, and nobody wants to taste diol. I learned to keep emergency eyewash stations clear, not buried under spare parts. Spill kits belong close to the action, not out in a storage shed. Actual training matters more than a line in the manual: run drills, walk the team through spill response, show what’s in the MSDS instead of shoving it in a drawer.

Nobody brags about “just another safe day,” but health is no accident—especially with compounds that don’t come with warning signs blaring from the bottle. Even mild exposures can turn serious, especially where safety culture runs thin or turnover stays high. My years working next to long-haul process operators and young techs lining up to start their chemical careers taught me plenty: habits matter, and good habits protect everyone. Let’s keep it that way, with 1,14-Tetradecanediol or anything else on the line.

1,14-Tetradecanediol stands out in the diol family with its fourteen-carbon chain capped at both ends by hydroxyl groups. I’ve handled it directly in the lab, so I’ve seen firsthand what distinguishes this compound. Chemists, manufacturers, and product developers look for reliable information on its solubility while weighing up options for plastics, coatings, or specialty chemicals.

In the most practical terms, 1,14-Tetradecanediol proves almost impossible to dissolve in water. Its long, nonpolar aliphatic chain pushes water molecules away. I remember watching the grains clump together at the bottom of a beaker — no matter how much I stirred, those white crystals refused to disappear in water. This aligns with published data: water solubility for this compound drops below a few milligrams per liter at room temperature.

Switching to organic solvents delivers much better results. Warm ethanol, acetone, and even chloroform take up 1,14-Tetradecanediol with little encouragement. These solvents accommodate long-chain molecules, so you see almost complete dissolution given enough solvent. A team at BASF published work demonstrating solubility in ethanol over 25 grams per liter, which is consistent with the way similar fatty diols behave.

Temperature plays a role. During one project, dissolving 1,14-Tetradecanediol in ethanol at 60°C reduced waiting times and left no visible residue. Cooling the solution, though, risked recrystallization — a challenge for manufacturers looking at storage or transport issues. Keeping mixtures above the melting point (about 87°C) keeps everything fluid, but bulk processing rarely happens at those temperatures because it costs more energy.

For producers of polyesters or specialty lubricants, poor water solubility means fewer headaches with finished product stability. Oils and coatings demand building blocks that withstand sweating, humid storage, or accidental water contact. Seeing this property as an advantage rather than a drawback makes sense for chemists designing new performance materials.

Any technician trying to incorporate this diol into a water-based system faces limitations. Surfactants or emulsifiers sometimes create workarounds, but the result usually falls short of true dissolution. In real-world settings, stable dispersions can look cloudy and eventually separate out, leaving a less reliable product. You can push for compatibility with high-shear mixing or by pairing with other alcohols, though costs and added complexity usually increase.

In the lab, creating pre-mixes in compatible organic solvents gets the job done. Diluting the diol in a solvent before adding it to a process avoids clumping and speeds up blending. On an industrial scale, process engineers opt for solvent-free extrusion or melt-processing, where the diol softens and mixes directly with other ingredients at elevated temperatures. This method lowers the need for aggressive solvents and works well for plastics and resins.

From my own projects, switching formulation strategy instead of battling solubility often yields smarter results. If a product must stay water-clear, I’ll pick shorter-chain diols. For applications in hydrophobic matrices, using the full chain length pays off in better end-product performance. Regulatory documents, like European ECHA dossiers and US EPA summaries, back up safe handling for this molecule when processed in non-aqueous surroundings.

Solubility gets overlooked until it causes problems in the plant or the lab. 1,14-Tetradecanediol thrives where nonpolar formulations dominate. Success with this diol depends on matching it to the right solvent and process — only then does its full value come through, both in everyday products and in specialty applications.

Anyone who's worked with specialty chemicals knows safe storage spells the difference between a good day and a disaster. 1,14-Tetradecanediol, which shows up as a waxy solid with a faint odor, doesn't seem dangerous at first glance. But underestimating even a simple diol can spell trouble. Fact is, the right storage extends shelf life, minimizes contamination, and protects folks who handle the substance every day.

1,14-Tetradecanediol melts at about 80°C and dissolves in alcohol but barely reacts with water. Leaving an open bag or drum of the stuff in a humid shop invites clumping and slow degradation. In my experience working with mid-chain diols, a dry, cool, and dark spot helps maintain the compound’s consistency and purity.

Direct sunlight triggers slow yellowing. Temperature swings cause condensation in containers. These small things chip away at a product’s predictability in processes as diverse as surfactant production and polymer modification. The evidence is easy to see: a sticky mess at the bottom of a drum means moisture or careless sealing allowed in contaminants.

Steel drums or thick-walled HDPE containers hold up against environmental hazards and ward off pests. Keeping them sealed doesn’t just stop moisture and dust. It prevents cross-contamination with other materials—especially in a busy plant. From experience, I’ve seen more than enough ruined batches from tiny lapses in protocol.

Breakrooms aren't storage spaces, and stuff stacked in narrow aisles invites accidents. A dedicated area, with labeled shelving and secondary spill containment, lowers both frustration and risk. Storage below 25°C protects against softening and sweating but avoids the low temps that make the solid tough to handle. I prefer logbooks at the entrance—details like date opened and batch numbers go a long way if a recall ever comes into play.

Reading material safety data sheets only gets you so far. Training builds judgment. Folks need to know why airtight closure matters and what happens if someone forgets to put the lid back on. Regular visual checks pick up the early signs of yellowing or crystallization before they affect batches downstream. There’s value in short, direct reminders during safety meetings to keep everyone alert.

Working without gloves or eye protection isn’t worth testing. Skin exposure leaves behind fatty residues that seem harmless until irritation sets in hours later. I’ve had colleagues who thought they could get away with complacency, only to pay with persistent dermatitis. Good habits aren’t about paranoia—they protect people and the final product.

Many mishaps begin with small oversights: a misplaced drum, a forgotten seal, a vague label. Building a safety culture where everyone can spot and fix these issues matters more than any one piece of advice. Regular drills, honest conversations, and clear accountability change habits for the better. In my years around chemical warehouses, the best results always came from teams where each worker owned their corner of the process.

| Names | |

| Preferred IUPAC name | tetradecane-1,14-diol |

| Other names |

1,14-Dihydroxytetradecane

Tetradecane-1,14-diol |

| Pronunciation | /ˌwʌn.wʌnˈfɔːr tɛt.rəˈdiːkəˌneɪnˌdaɪ.ɒl/ |

| Identifiers | |

| CAS Number | 111-20-6 |

| 3D model (JSmol) | /data/Jmol/models-2.0/TETRADECA-1,14-DIOL.mol |

| Beilstein Reference | 629881 |

| ChEBI | CHEBI:30015 |

| ChEMBL | CHEMBL140598 |

| ChemSpider | 151080 |

| DrugBank | DB07811 |

| ECHA InfoCard | 03b930e0-867d-4a62-ab9f-5d591e58c0c8 |

| EC Number | 01-2119974597-14-0000 |

| Gmelin Reference | 82881 |

| KEGG | C19601 |

| MeSH | D017175 |

| PubChem CID | 81284 |

| RTECS number | XD1400000 |

| UNII | GEC39P0EAF |

| UN number | UN1993 |

| Properties | |

| Chemical formula | C14H30O2 |

| Molar mass | 230.38 g/mol |

| Appearance | White solid |

| Odor | Odorless |

| Density | 0.912 g/cm3 |

| Solubility in water | Insoluble in water |

| log P | 1.94 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 14.40 |

| Basicity (pKb) | 3.68 |

| Magnetic susceptibility (χ) | -86.0e-6 cm³/mol |

| Refractive index (nD) | 1.459 |

| Viscosity | 22.6 cP (80°C) |

| Dipole moment | 2.67 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 481.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -393.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -8379.7 kJ/mol |

| Pharmacology | |

| ATC code | A14AB10 |

| Hazards | |

| Main hazards | Causes serious eye irritation. |

| GHS labelling | GHS labelling for 1,14-Tetradecanediol: `"Not a hazardous substance or mixture according to the Globally Harmonized System (GHS)"` |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | May cause respiratory irritation. |

| Precautionary statements | Precautionary statements: P280, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-1-0 |

| Flash point | 174 °C |

| LD50 (median dose) | LD50 (median dose): > 5 g/kg (rat, oral) |

| NIOSH | Not established |

| PEL (Permissible) | PEL not established |

| REL (Recommended) | 3 mg/m³ |

| Related compounds | |

| Related compounds |

1,12-Dodecanediol

1,16-Hexadecanediol 1,10-Decanediol 1,6-Hexanediol |