People have tinkered with organic molecules for decades, and 1,10-dichlorodecane is one of those compounds that quietly reflects the growth of industrial chemistry. Its story stretches back to the early expansion of the petrochemical sector. Companies seeking better intermediates for making surfactants, specialty lubricants, and chemical syntheses looked to chlorinated alkanes. Evidence of its relevance popped up in the literature as early as the 1960s, with researchers hunting for stable, versatile chain compounds that could introduce functional groups at both ends of a long carbon structure. The growth of industrial laboratories in Europe and North America allowed this molecule to move from mere academic curiosity to a specialty chemical that found practical slots in several sectors.

1,10-Dichlorodecane doesn’t make waves on supermarket shelves, but ask anyone working with advanced materials, and they’ll nod in recognition. Its molecular structure—ten carbons linked in a straight chain with a chlorine leaving group on each end—makes it a favorite for industries that need controlled reactivity. Manufacturers use it to create custom surfactants, plasticizers for unique resins, and in some cases, as a model compound for degradation and fate studies. Despite the lack of mass-market recognition, the importance of this chemical underscores how the building blocks of so many products start their life far from the spotlight.

1,10-Dichlorodecane holds its own among chlorinated hydrocarbons. It comes as a clear to pale-yellow oily liquid, carrying a faint odor that reminds some old-timers of cleaning chemicals. The boiling point hovers north of 300°C—enough to require proper equipment for distillation. Its density outruns that of water, so spills quickly settle at the bottom of containers. The reactivity boils down to those terminal chlorine atoms, ready to undergo nucleophilic substitution or even elimination with the right trigger. Chemical literature shows stability under regular storage, but under intense heat or in the presence of strong bases, the molecule willingly changes shape.

Technical grades of 1,10-dichlorodecane usually roll out at purities above 97%, unless a user specifically requests something tailored for research. Labels follow strict guidelines. Labels must show hazard statements tied to the GHS system, including warnings about skin and eye irritation and the environmental hazards if the chemical leaks into waterways. Packing comes in HDPE drums or glass bottles, with tamper-evident seals that keep the product clean and unadulterated from the producer to the end-user. Batch numbers, production dates, and regulatory classification codes dominate the technical data stickers, leaving no room for ambiguity. I’ve found that large suppliers often provide certificates of analysis for each lot, a peace of mind for labs hoping to avoid any costly contamination.

This molecule emerges from a straightforward, if robust, process in the world of chlorinated intermediates. Constructing 1,10-dichlorodecane starts with decane—a straight ten-carbon hydrocarbon common in petroleum fractions. Chemists employ chlorination at terminal positions, often with a controlled mix of ultraviolet light and chlorine gas. Some syntheses route through 1,10-decanediol as a precursor, first converting the diol to the corresponding dimesylate or ditosylate, then substituting with chloride ion. Either pathway demonstrates the discipline needed to ensure site-selective reaction, since indiscriminate chlorination would produce a confusing mess of isomers. The resulting product needs rigorous distillation and washing to eliminate side-products, unreacted feedstock, and color bodies. Plants with experience in multi-ton scale chlorination rely on scrubbing off residual chlorine and vent gases, keeping both the operators and the environment safer.

The two terminal chlorines practically beg for further chemistry. They get replaced in syntheses with everything from amines to thiols, driving the creation of di-functionalized derivatives. In the lab, 1,10-dichlorodecane serves as a springboard for constructing large ring compounds, ionic liquids, or even dendrimers—a testament to the power of a simple, flexible backbone. Some processes swap one or both chlorines for azide, leading to click-chemistry building blocks. The decane chain resists oxidation under ordinary conditions, which is crucial for users aiming to keep side-products to a minimum. I’ve seen group research in university settings take advantage of these properties to build supramolecular structures, showing how this one molecule can underpin a range of high-end science.

Anyone hunting through catalogues might find 1,10-dichlorodecane under several tags. Common synonyms include Decamethylene dichloride, Decylene dichloride, and Decane, 1,10-dichloro-. Major chemical vendors might simply call it 1,10-DCD or just “DC-10.” CAS numbers help take away confusion, with 2162-98-3 regularly cited in documentation and shipping manifests.

Working with chlorinated compounds comes with a set of non-negotiable safeguards. Long sleeves, impervious gloves, goggles, and well-ventilated hoods take priority. 1,10-Dichlorodecane, like other related chemicals, irritates skin and eyes on direct contact. Poor handling leads to headaches or respiratory complaints, mostly from vapor inhalation. Companies that deal with bulk volumes must install spill containment, eye wash stations, and must train every technician on rapid decontamination. Transport rules demand proper labeling as an irritant and a potential aquatic toxin. Storage in tightly sealed containers away from heat sources sits at the top of every standard operating procedure. As someone who’s made mistakes with less volatile chemicals, I can’t overstate the payoff from careful, consistent training and rigid housekeeping.

Chemical manufacturers blend 1,10-dichlorodecane into several industrial value chains. Surface-active agent synthesis remains a cornerstone. Its bifunctionality helps craft specialty surfactants for cleaning up the toughest grime. Companies producing polymeric materials use it as a chain extender or cross-linking agent in advanced resins—enabling custom plastics for automotive and aerospace parts. Electronics manufacturing and laboratory R&D sometimes use the molecule as a linker or as a platform to hang other functional groups. Some specialty lubricants and hydraulic fluids benefit from its presence, especially in environments dealing with aggressive wear and tear. Though it never makes headlines, it powers the backbone of manufacturing.

Academic and industrial scientists push the boundaries of 1,10-dichlorodecane. Recent years brought an uptick in studies about its behavior as a contaminant proxy in environmental fate and transport models, offering insights into how “semi-volatile” organics move through soil and water. Labs specializing in green chemistry seek better ways to harness its two reactive handles for efficient, less polluting syntheses. Research into the bioaccumulation potential has picked up due to growing concern about persistent organic pollutants. Colleagues working in supramolecular chemistry use it as a spacing unit within larger, self-assembling structures, tapping the straight-chain stability and reactivity to control the shape and function of their molecular constructs.

Safety data for 1,10-dichlorodecane runs thin compared to more high-profile industrial chemicals. What we know comes from in vitro studies, occasional animal testing data, and analog research using related chloroalkanes, showing skin irritancy and the potential for mild respiratory effects. It tends to persist in the environment, resisting biodegradation. Regulators in Europe and North America keep a wary eye on its aquatic impact, as chronic low-level releases may disrupt sensitive ecosystems. Organizations such as the US EPA and ECHA roll out guidance on permissible exposure and accident prevention. I've seen lab managers err on the side of conservatism—treating even small spills with the seriousness of a major contamination event. The absence of broad toxicity data highlights the gap researchers need to fill, especially given the ongoing concern about long-chain chlorocarbons.

1,10-Dichlorodecane won’t land on magazine covers, but its importance grows as industries demand tailored, robust base chemicals. The molecule’s versatility sits well with the push toward engineered materials, particularly in sectors investing in new surfactant or polymer architectures. Regulatory frameworks press manufacturers to improve handling and disposal, pushing firms toward cleaner technology and tighter emission controls. Interest in green chemistry opens the door for bio-based synthesis or new catalytic routes, hoping to shed its environmental burden. For me, the lesson is simple: chemicals like this may never become household names, but they’re instrumental in knitting together the work of scientists, engineers, and manufacturers around the world who shape the future one compound at a time.

1,10-Dichlorodecane lands on the list of specialty chemicals that most people never hear about, yet it shapes manufacturing behind the scenes. This compound, built from a simple ten-carbon chain bookended by two chlorine atoms, belongs with the aliphatic chlorinated hydrocarbons. These molecules pop up across chemical and industrial landscapes. I first ran into 1,10-Dichlorodecane on an internship in an industrial lab, surrounded by clouds of unknowns. The reality struck me—lab ingredients don’t arrive from nowhere; they all lead back to choices made in offices, research papers, or boardrooms.

Many chemists pick 1,10-Dichlorodecane for its usefulness as an intermediate. On paper, this just means it bridges steps during synthesis. The longer I spent around production teams, the more I learned that intermediates act like runners in a relay—they don’t get the spotlight, but without them, nothing reaches the finish line. Factories and labs in specialty plastic, agricultural, and pharmaceutical fields buy it up as a building block. The extra chlorine gives makers more ways to create rare or customized molecules.

This chemical also finds a place as a solvent for tricky reactions. A solid solvent can turn a mess into a masterpiece, letting experiments run at high temperatures or helping dissolve other chemicals that stubbornly clump together in water. I saw colleagues use it to help reformulate coatings and lubricants that need to survive both chemical attack and harsh physical conditions.

What sticks out is the underlying push behind every canister of 1,10-Dichlorodecane: necessity collides with risk. Chlorinated hydrocarbons catch flak for their persistence—the molecules don’t like to break down in soil or water, and some bring toxicity along. The first time I handled one, the training went on for hours covering disposal, exposure, and emergency response. It makes sense why companies debate alternatives and why regulators turn a hard eye to anything with chlorine in its name.

The chemical world doesn’t always turn on what’s safe; it turns on what’s available and what the market demands. Still, knowledge about the exposures goes further today than it did even ten years ago. Workers benefit from tighter controls, like enclosed handling or realtime air monitoring. Legislators aren’t shy about stepping in to set exposure limits or force companies to rethink production.

No single solution will fix the risks tied to compounds like 1,10-Dichlorodecane. Switching away isn’t as simple for factories as flipping a light switch, because downstream products often depend on the properties a molecule like this provides. Some industries experiment with greener alternatives: hydrocarbons with oxygen groups or molecules that snap apart more easily in the wild. But new solutions call for time, research, and money. Partnerships with universities and transparent data sharing help nudge things along. In my own work, I’ve seen the most honest discussions in rooms where regulators, chemists, and local leaders all have a seat at the table—everyone wants to protect jobs, the environment, and the community.

Understanding these chemicals pushes decision-makers to ask hard questions about what gets used, how waste gets managed, and where old habits need a shakeup. It’s not just about chemistry; it’s about the people who live near factories, the farmers who rely on safer products, and the workers at the plant who want to go home healthy.

People rarely think twice about the chemicals used in industrial processes or in consumer products. Yet, many basic compounds shape health outcomes, especially for workers and communities living near manufacturing sites. 1,10-Dichlorodecane is a good example. Used as an intermediate in making other chemicals, it doesn’t often draw headlines. Still, real questions exist about its impact.

1,10-Dichlorodecane counts as a halogenated hydrocarbon. Compounds in this group have a long history of surprising both scientists and regulators with effects nobody expected. Experiences with relatives such as polychlorinated biphenyls (PCBs) and certain chlorinated solvents have shown that the human body struggles to break down molecules with multiple chlorine atoms. These substances stick around in fat tissues for weeks to months. Over time, this persistence can lead to trouble.

Existing toxicological profiles do not always drill down on 1,10-Dichlorodecane specifically. Some animal studies point to the potential for liver and kidney stress if high amounts reach the bloodstream. Workplace studies suggest repeated skin contact or inhalation of vapors causes irritation. The heavier the chemical, the slower it leaves the body. Chronic low-level exposure has raised concerns, even if major agencies such as the EPA have not set strict exposure limits for this particular variant.

Communities living near chemical plants have taught researchers a lot about “safe” levels not always aligning with lived experience. Noses notice odd smells, eyes tear up, and skin itches long before official readings suggest a problem. Several times, local complaints about strong odors from dichlorinated compounds pushed independent testing, revealing leaks or spills that managers missed.

Parents worry about children playing in grass near chemical storage tanks. Workers speak out when rashes or headaches become common after shifts. Grassroots pressure often pushes policymakers to look beyond what is officially listed as hazardous, towards what keeps communities truly healthy.

It makes sense to treat 1,10-Dichlorodecane much like its better-understood cousins. Keeping good ventilation in indoor workspaces, using personal protective equipment such as gloves and masks, and routinely inspecting storage containers go a long way. After handling, washing up with soap and water protects skin and reduces residue on personal items. I recall stories from chemical plant workers who learned to trust their noses and support co-workers reporting odd reactions—safety cuts across job titles.

Manufacturers tracking usage and disposal can minimize leaks that reach waterways or soil. Families near industrial sites deserve answering when asking, “What’s in our air and water today?” Offering transparent testing results and respecting community concerns, instead of deflecting, builds real trust. Medical monitoring for those with long-term exposure makes sense, even without large studies showing clear problems—acting with caution often prevents bigger health issues later.

No one chemical shapes all risk, yet each one deserves honest scrutiny. New information about 1,10-Dichlorodecane will certainly emerge as more research unfolds. Meanwhile, sharing data, empowering workers, and valuing neighborhood reports offer protection, especially for people who deal with chemical exposure daily. Staying informed and pressing for responsible industry behavior helps keep invisible risks from becoming everyday health problems.

1,10-Dichlorodecane is a clear liquid and falls under organochlorine compounds. Anyone handling chemicals like this learns pretty quickly that simple stowing away doesn’t cut it. The hazards tied up in its chlorinated structure — volatility, potential toxicity, and reactivity — mean storage calls for attention beyond a label and a shelf.

Exposure to chemicals such as 1,10-Dichlorodecane puts skin, eyes, and lungs at risk. Chemical storage in real-world labs has taught me that even trace fumes can trigger reactions in sensitive staff or lead to headaches after longer exposure. For safety, ventilation isn’t negotiable. A well-maintained fume hood or local exhaust system reduces vapor buildup.

Glass often holds up best against chlorinated solvents. HDPE containers work in a pinch, but never trust flimsy or unidentified plastics. Over time, I’ve seen subpar containers degrade, turning into a leaking mess. Regular inspections of seals and container walls help catch trouble early. Labels come off, ink fades — it pays to relabel whenever there’s doubt.

Storing 1,10-Dichlorodecane inside a cool, dry space limits both evaporation and accidental activation of fire suppression systems. Direct sunlight and fluctuating temperatures raise vapor pressure inside containers, which increases risk of leaks or even rupture. Stash containers away from windows or heat sources. Steady room temperature, between 15°C and 25°C, feels about right.

Chlorinated hydrocarbons don’t always get along with other lab staples. Acids, alkali metals, and strong oxidizers can trigger dangerous reactions. At my last workplace, storing solvents too close led to a shelf fire from leaked vapors and a nearby open container of nitric acid. Make sure 1,10-Dichlorodecane has its own, dedicated section — ideally in a flammable liquid cabinet lined with chemical-resistant trays to catch any spills.

Spills can’t always be stopped by a locked cabinet. Emergency plans, with proper absorbents like activated charcoal or vermiculite, need to be close at hand. After a minor spill, evacuation can be avoided only by reacting instantly and having clear instructions posted right on the cabinet. Also, staff training makes the difference; no poster replaces hands-on drills.

Good airflow feels obvious, but air monitoring proves just as important. Simple badges or fixed sensors for chlorinated vapors let everyone know if something’s wrong before someone gets sick. After a friend collapsed in a poorly ventilated storeroom, I won’t trust “nose-tested” air quality alone again.

Track chemical stocks with accuracy, including dates when containers are opened. Keep access restricted to trained staff. Rules from OSHA, the EPA, and sometimes local fire departments set minimum safety standards. Regular self-audits or third-party checks flag gaps in compliance before regulators find them. Skipping those isn’t worth the fines or the risk to health.

Simple preventative steps take priority: sensible quantities, secondary containment, and regular training. Better practices mean fewer emergencies, fewer health complaints, and a lot less paperwork. 1,10-Dichlorodecane storage isn't about luck — it rewards the labs that respect both the letter and the spirit of chemical safety.

Few people outside laboratories ever come across 1,10-dichlorodecane, but for those who do, health risk stays on the mind. This chlorinated hydrocarbon has a reputation for being harmful to eyes, skin, and lungs. Breathing in its vapors or getting it on bare hands can lead to short-term irritation and possibly long-term damage. In my years working around industrial chemicals, I've seen mistakes with solvents lead to trips to the ER and long-term scars, both physical and personal. The importance of careful handling isn’t just an official memo—it's a lesson learned in the field and sometimes at a painful cost.

Nobody in their right mind handles this compound without proper gear. Chemical splash goggles, gloves made from nitrile or neoprene, and a long-sleeved lab coat form the basic uniform. Always work with a fume hood or provide ample ventilation. Even after a day surrounded by high standards, one slip—touching a contaminated doorknob, rubbing an eye, skipping a glove—can undo months of vigilance. Keeping clean habits stops accidents before they start. I've seen veteran techs use disposable pipettes and keep a clean bench, which sets the tone for the younger crew. Washing hands before leaving the lab is non-negotiable.

This chemical stores best in clearly labeled, tightly sealed glass or compatible plastic containers. Store these far from heat sources or sunlight, since both can speed up degradation and invite dangerous leaks. Segregate away from oxidizers and strong bases, since chemical incompatibilities can spark fires or explosions. A spill kit—absorbent pads, neutralizer, disposal bags—should be within arm’s reach. During inventory checks, watch container integrity. Small cracks add up to big headaches down the line.

Pouring leftover dichlorodecane down the drain poisons water systems and disrupts the lives of people downstream, not to mention the ecosystem. Environmental agencies, including the EPA, put strict rules in place for a reason: this chlorinated compound can persist in groundwater and build up in living things. Improper disposal leads to fines, lawsuits, and environmental cleanup that can bankrupt small operators. Companies large and small arrange collection with licensed hazardous waste contractors who process organic halides through incineration under high heat, destroying harmful compounds. At home, it's tempting to cut corners, but nobody wants to be the reason for fish kills or health warnings in the news.

The best safety programs start before anything is poured into a flask. Regular safety meetings, real-life spill drills, and open conversations about near-misses make a difference. Supervisors who walk the floor and check PPE racks aren’t wasting time—they’re preventing both injuries and lawsuits. Fact sheets and up-to-date Safety Data Sheets hang in view, reminding workers what’s at stake. Even after decades, complacency creeps in, so checklists and buddy systems hold everyone accountable.

Industries now rethink their need for 1,10-dichlorodecane, exploring substitutes that offer similar performance with fewer risks to people and the planet. Chemists often trial new solvents, review their toxicity profiles, and swap out hazardous materials for safer blends. Waste minimization starts with smart ordering—a full drum sitting for years creates more danger than the small bottle used up each quarter. Cleaner chemistry sometimes means changing the process, not just the ingredients. The culture of safety grows stronger when every worker feels responsible for not just themselves, but the community outside the lab walls.

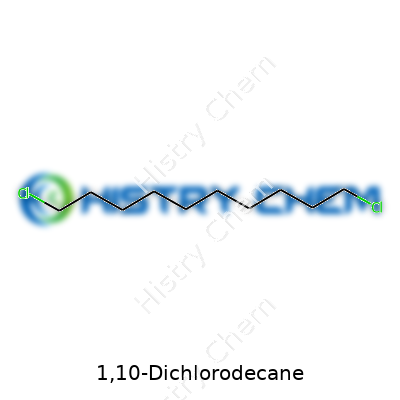

Chemistry classes often feel tough—until you get the chance to take apart a molecule like 1,10-Dichlorodecane. This compound carries a simple backbone, stretching out ten carbon atoms long, with a chlorine atom attached to each end. Its chemical formula reads C10H20Cl2. Every carbon except for the first and last is fully loaded with hydrogen atoms, while the two end carbons each hold a chlorine. Seen on paper, the structure runs: Cl-CH2-(CH2)8-CH2-Cl.

During my lab days, I saw first-hand how subtle tweaks—like swapping a hydrogen for a chlorine—can utterly change how a molecule acts. This compound’s symmetry is a lesson in molecular design: adding chlorine atoms at each end shields them away from the middle of the chain, affecting how the molecule handles heat or reacts with other substances. This design explains why these molecules are often more stable, less likely to evaporate, and tougher against some chemical changes.

For companies making specialty chemicals, having both chlorines at the end creates two “handles.” Those ends act like anchor points, letting chemists build larger, more custom compounds for oil, plastic, or cleaning industries.

After working as a lab assistant, I watched a co-worker get careless with a splash of chlorinated liquid—his gloves kept him safe, but the lesson stuck. Chlorinated compounds like 1,10-Dichlorodecane stand out for their persistence in the environment. They put up a fight against natural breakdown, sometimes sticking around in ecosystems for years.

Toxicity is an old story with chlorinated hydrocarbons. Some can build up in living things. Their effects depend on how the chlorine sits on the carbon chain. Long chains with just a couple chlorines show lower toxicity than those heavily loaded with halogens. Still, nobody in the chemical business skips gloves and goggles, and any waste gets locked down to keep it out of waterways.

Facilities that process plastics or lubricants value compounds like this for the way they improve smoothness or resistance to certain chemical reactions. Whenever a chain gets chlorinated—especially at both ends—it behaves differently. These chemicals often end up as intermediates, stepping stones toward more complicated products, or playing supporting roles in specialty industrial fluids.

Looking forward, chemists and manufacturers could limit environmental risk by using substitutes with similar properties but faster breakdown—or by designing recycling paths that keep these chemicals from building up outside factories. Industry groups evaluated halogenated hydrocarbons for decades. In the coming years, green chemistry could turn those lessons into new formulas that use renewable feedstocks, minimize waste, and improve workplace safety without losing product quality.

Clear-eyed, fact-based decisions rely on up-to-date research. The more is known about how and where these compounds end up, the more choices open up for handling them properly.

| Names | |

| Preferred IUPAC name | 1,10-dichlorodecane |

| Other names |

Decamethylene dichloride

Dichlorodecane 1,10-Dichlordecan |

| Pronunciation | /ˈwʌnˌtɛn daɪˈklɔːrəˌdiːkeɪn/ |

| Identifiers | |

| CAS Number | 10171-23-4 |

| 3D model (JSmol) | `CCCCCCCCCC(Cl)Cl` |

| Beilstein Reference | 1718737 |

| ChEBI | CHEBI:78353 |

| ChEMBL | CHEMBL49016 |

| ChemSpider | 12014 |

| DrugBank | DB07886 |

| ECHA InfoCard | 03e188b2-2a45-4018-985f-5186a1a8b32b |

| EC Number | 208-787-6 |

| Gmelin Reference | 37768 |

| KEGG | C19230 |

| MeSH | D010836 |

| PubChem CID | 12459 |

| RTECS number | JR2100000 |

| UNII | U9R0K3GPLA |

| UN number | UN3082 |

| CompTox Dashboard (EPA) | DTXSID7024573 |

| Properties | |

| Chemical formula | C10H20Cl2 |

| Molar mass | 227.18 g/mol |

| Appearance | Colorless liquid |

| Odor | Odorless |

| Density | 1.01 g/mL at 25 °C(lit.) |

| Solubility in water | Insoluble |

| log P | 5.76 |

| Vapor pressure | 0.012 mmHg (25°C) |

| Acidity (pKa) | 14.2 |

| Magnetic susceptibility (χ) | -7.76e-6 cm³/mol |

| Refractive index (nD) | 1.486 |

| Viscosity | 3.05 mPa·s (25 °C) |

| Dipole moment | 2.02 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | “519.7 J·mol⁻¹·K⁻¹” |

| Std enthalpy of formation (ΔfH⦵298) | -225.05 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -6617.7 kJ/mol |

| Pharmacology | |

| ATC code | V09AX02 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes skin irritation. Causes serious eye irritation. Toxic to aquatic life with long lasting effects. |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P261, P273, P280, P301+P312, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1,2,0 |

| Flash point | 113 °C (235 °F; 386 K) (Closed cup) |

| Autoignition temperature | 215 °C (419 °F; 488 K) |

| Explosive limits | Explosive limits: 0.9–6.3% |

| Lethal dose or concentration | Lethal dose or concentration: LD₅₀ (oral, rat) > 5000 mg/kg |

| LD50 (median dose) | LD50 (median dose): 3.06 g/kg (rat, oral) |

| NIOSH | Not established |

| PEL (Permissible) | Not established |

| REL (Recommended) | 0.5 ppm |

| IDLH (Immediate danger) | Unknown |

| Related compounds | |

| Related compounds |

1,10-Diiododecane

1,10-Dibromodecane 1,10-Difluorodecane |